Insulating ceramic and its preparation method, and multi-layer ceramic capacitor

A technology of insulating ceramics and internal electrodes, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., can solve the problems of increased electrostatic capacitance, etc., and achieve the effects of high insulation resistance, low dielectric loss, and long insulation life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] First, weigh a certain weight of TiCl as the starting material for the preparation of the main component 4 and Ba(NO 3 ) 2 , react the two with oxalic acid to obtain a tetrahydrate barium titanyl oxalate BaTiO(C 2 o 4 )·4H 2 Precipitation of O. Decompose the precipitate by heating at 1000°C or higher to obtain BaTiO 3 , the BaTiO 3 Grinding to get BaTiO 3 powder.

[0069] In the ball mill, the auxiliary component Dy 2 o 3 , NiO, MnO 2 and SiO 2 According to the proportions in Table 1, wet mixing was carried out respectively, and the obtained mixture was calcined at 1000° C. for 2 hours, and then ground to obtain calcined co-component powder.

[0070] According to the ratio shown in Table 1, the BaTiO 3 The powder and the calcined co-component powder are mixed to obtain a powder mixture as an insulating ceramic raw material powder.

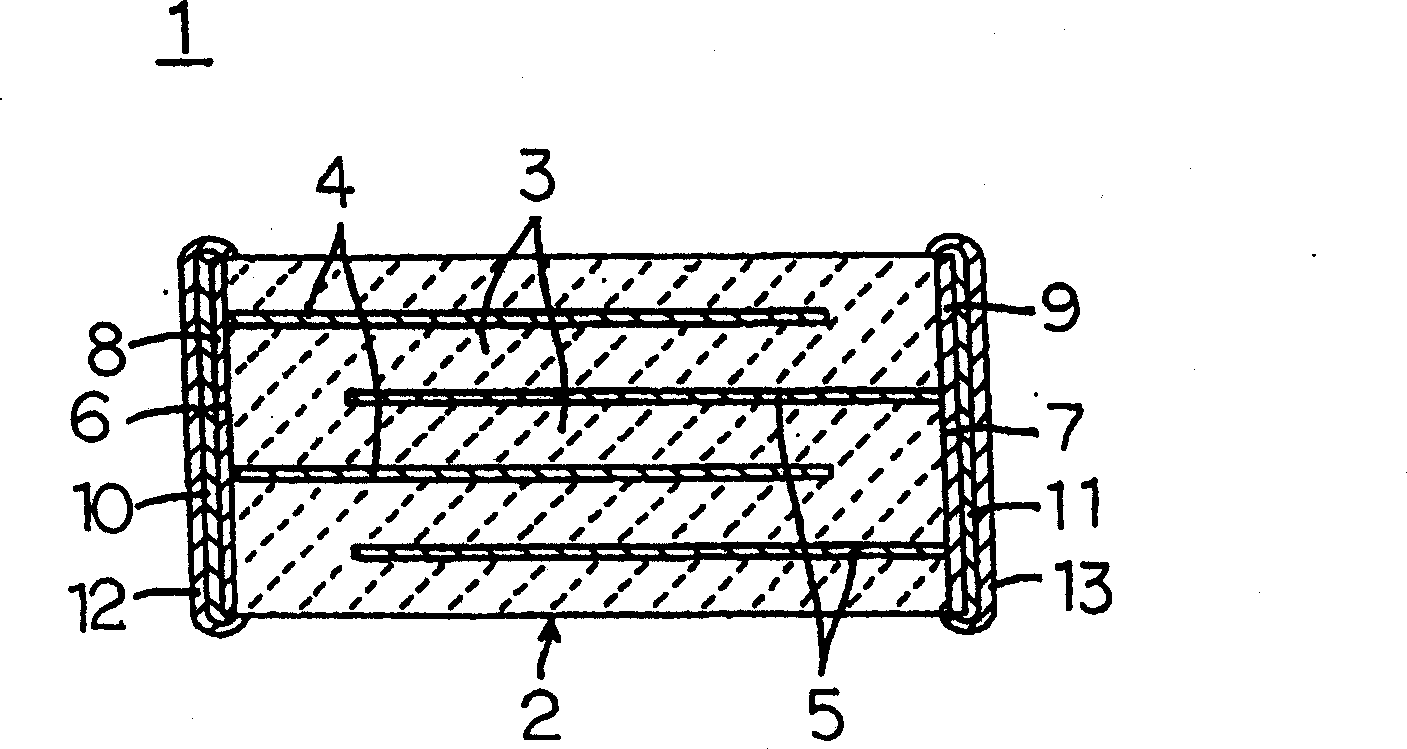

[0071]In a ball mill, a polyvinyl butyral binder and an organic solvent such as ethanol are added to the powder mixtur...

Embodiment 3

[0082] Adopt the method for embodiment 1 to prepare multilayer ceramic capacitor, difference is to adopt respectively as shown in table 1 (Ba 0.90 Ca 0.10 )(Ti 0.90 Zr 0.09 f 0.01 )O 3 as an ABO 3 Components, (Y 2 o 3 , Tm 2 o 3 )-NiO-SiO 2 As an auxiliary component, MgO was used as an added component, and fired at the temperature shown in Table 2 to obtain a multilayer ceramic capacitor. In this process, ABO 3 Components used (Ba 0.90 Ca 0.10 )(Ti 0.90 Zr 0.09 f 0.01 )O 3 By mixing BaO, CaO, TiO 2 , ZrO 2 and HfO 2 And calcined the resulting mixture to prepare. Comparative example 3

Embodiment 4

[0085] Adopt the method for embodiment 1 to prepare multilayer ceramic capacitor, difference is to adopt respectively as shown in table 1 (Ba 0.95 Sr 0.05 )(Ti 0.95 Zr 0.05 )O 3 as an ABO 3 Components, (Er 2 o 3 , MnO 2 ) as auxiliary component, V 2 o 5 , SiO 2 and MgO as additional components, and fired at the temperature shown in Table 2 to obtain multilayer ceramic capacitors. In this process, ABO 3 Components used (Ba 0.95 Sr 0.05 )(Ti 0.95 Zr 0.05 )O 3 By mixing BaO, SrO, TiO 2 and ZrO 2 And calcined the resulting mixture to prepare. Comparative example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Physical dimension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com