Flash memory cell and its preparing process

A storage unit and flash technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as poor reliability of high-power consumption storage units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

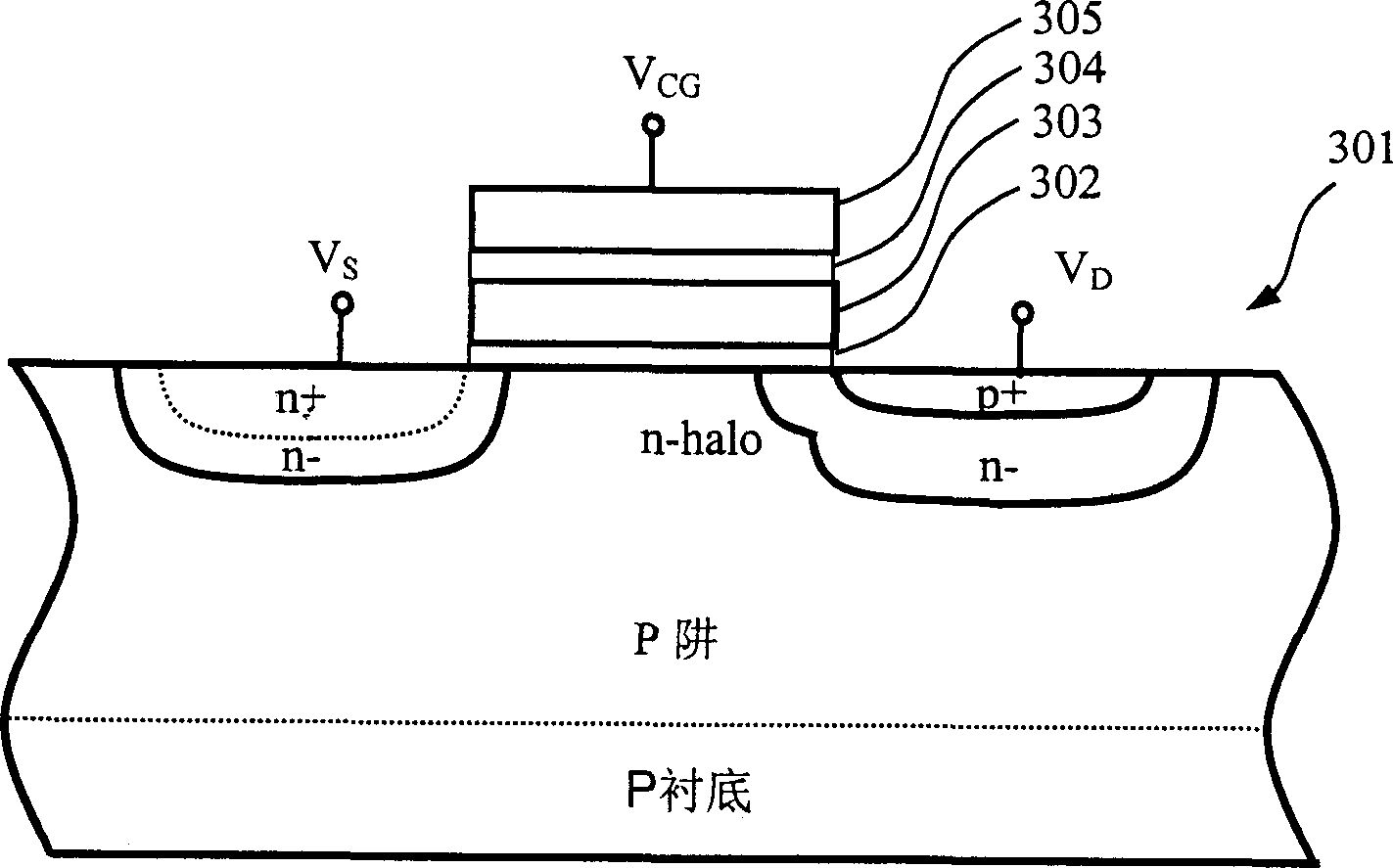

[0035] image 3 is a schematic cross-sectional view of a flash memory unit 301 on a p-type semiconductor substrate. It contains: a tunnel thin oxide layer 302 formed on the p-type semiconductor substrate; a stacked gate structure located on the tunnel thin oxide layer 302, the stacked gate structure includes a floating gate 303 and a control gate 305, The floating gate 303 and the control gate 305 are electrically isolated by a silicon dioxide / silicon nitride / silicon dioxide composite dielectric layer 304; a source region is formed in the first layer of the stacked gate structure composed of the floating gate 303 and the control gate 305. In the substrate at the edge, the source region includes a low-concentration phosphorus implanted n-source region located in the substrate at the first edge of the stacked gate structure and extending under the stacked gate structure, and a high An n+ source region implanted with arsenic concentration is located in the n-source region at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com