Lithium carbonate crystal separating process from carbonate-type bittern by means of solar battery

A crystallization, carbonate type technology, applied in the direction of lithium carbonate;/acid carbonate, solution crystallization, etc., can solve the problems of poor heat storage capacity, easy damage to the plastic shed, time-consuming and laborious salt collection, etc. Achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

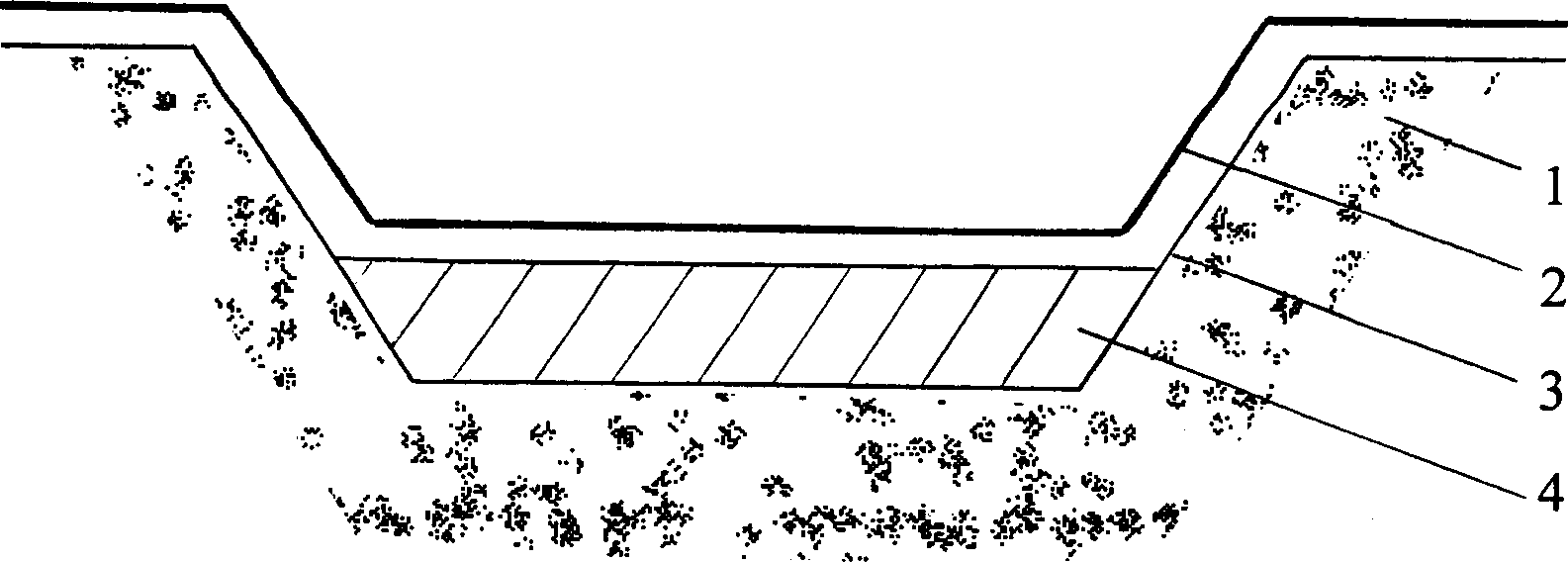

[0024] The solar pool lighting area is 1936 meters 2 , The slope ratio is 1:1, the inner wall of the pool is covered with black geomembrane as a liner, and the bottom of the pool is made of magnesite for insulation.

[0025] Using high-lithium, high-carbonate-brine in salt lakes as raw materials, it is concentrated to obtain Li + Lithium-rich brine with a concentration of 2.64g / l controls the depth of the lithium-rich brine in the solar pond to about 2.5m; pours about 50cm of clean fresh water into the brine layer, and the total depth of the brine and freshwater layers in the solar pond is about 3m. The operation time is from March 19 to May 4, 2002. After 40 days of solar energy storage, the temperature of the solar pool energy storage area reaches about 31.5°C, and the high-lithium mixed salt with a thickness of about 3mm is enriched in the pool and crystallized. The grade of lithium carbonate contained in the mixed salt is 83.1%. During the lithium sinking period, accordi...

Embodiment 2

[0027] The solar pool lighting area is 1936 meters 2 , The slope ratio is 1:1, the inner wall of the pool is covered with black geomembrane as a liner, and the bottom of the pool is made of magnesite for insulation.

[0028] The brine with high lithium and high carbonate in the salt lake is used as raw material, and after concentration, Li + Lithium-rich brine with a concentration of 1.8g / l controls the depth of the lithium-rich brine in the solar pool to about 1.69m; pours about 40cm of clean fresh water into the brine layer, and the total depth of the brine and freshwater layers in the solar pool is about 2.09m . The operation time is from May 17th to June 9th, 2002. After 23 days of absorbing solar heat and storing heat, the temperature of the solar pool energy storage area reaches about 40°C, and the pool is enriched with high-lithium mixed salt with a thickness of about 3mm, which crystallizes The grade of lithium carbonate contained in the mixed salt is 81.6%. During ...

Embodiment 3

[0030] The solar pool lighting area is 1936 meters 2 , The slope ratio is 1:1, the inner wall of the pool is covered with black geomembrane as a liner, and the bottom of the pool is made of foam plastic for heat insulation.

[0031] The brine with high lithium and high carbonate in the salt lake is used as raw material, and after concentration, Li + Lithium-rich brine with a concentration of 1.59g / l, control the depth of lithium-rich brine in the solar pool to about 1.5m; pour about 30cm of clean fresh water into the brine layer, at this time the total depth of brine and freshwater layers in the solar pool is about 1.8m . The operation time is from June 4th to June 30th, 2002. After 26 days of absorbing solar heat and storing heat, the temperature of the solar pool energy storage area reaches about 47°C, and the high-lithium mixed salt with a thickness of about 3mm is enriched in the pool and crystallized. The grade of lithium carbonate contained in the mixed salt is 82.8%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com