Production method of single-layer organic photocon

A technology for a photoconductive device and a manufacturing method, which is applied in optics, instruments, electrical recording techniques, etc., can solve problems such as failure to be widely used, low photosensitivity, and difficult control of process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

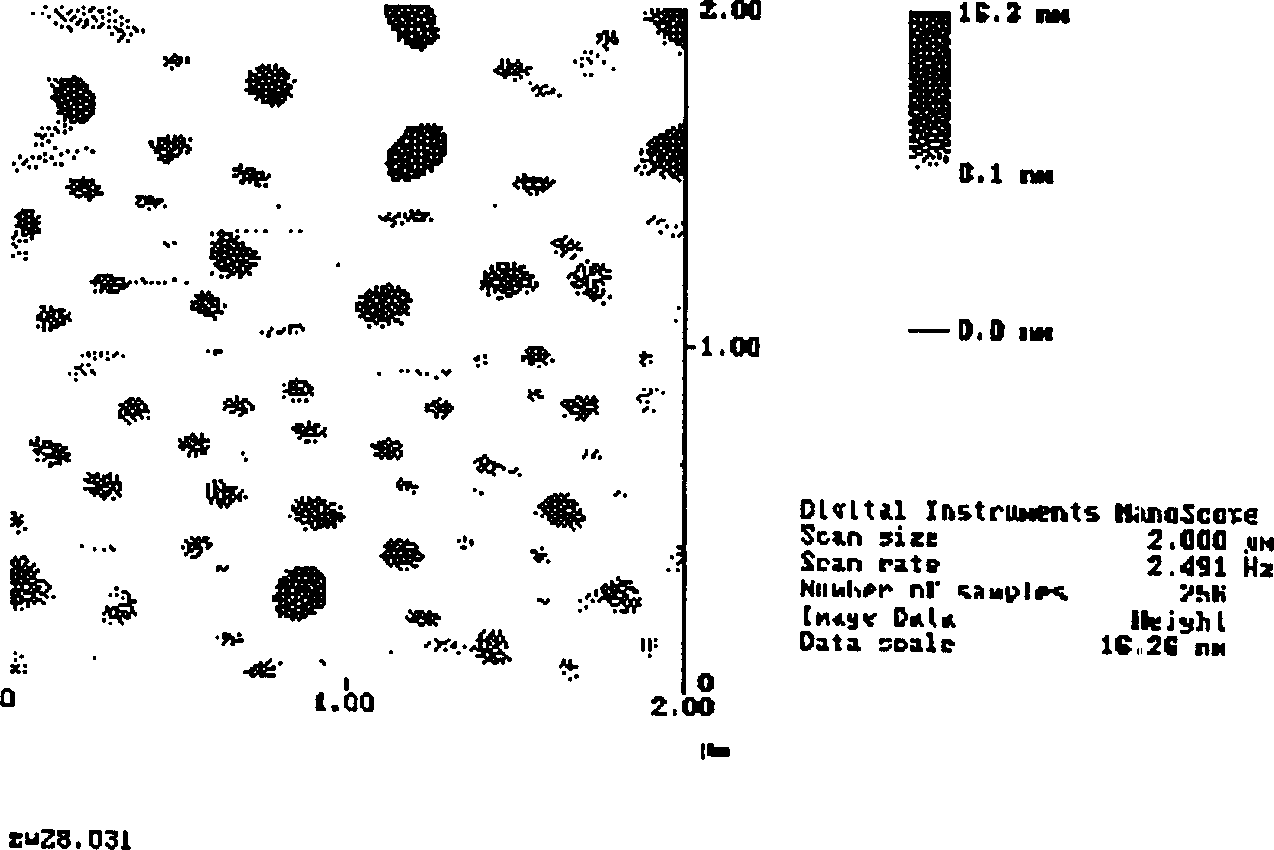

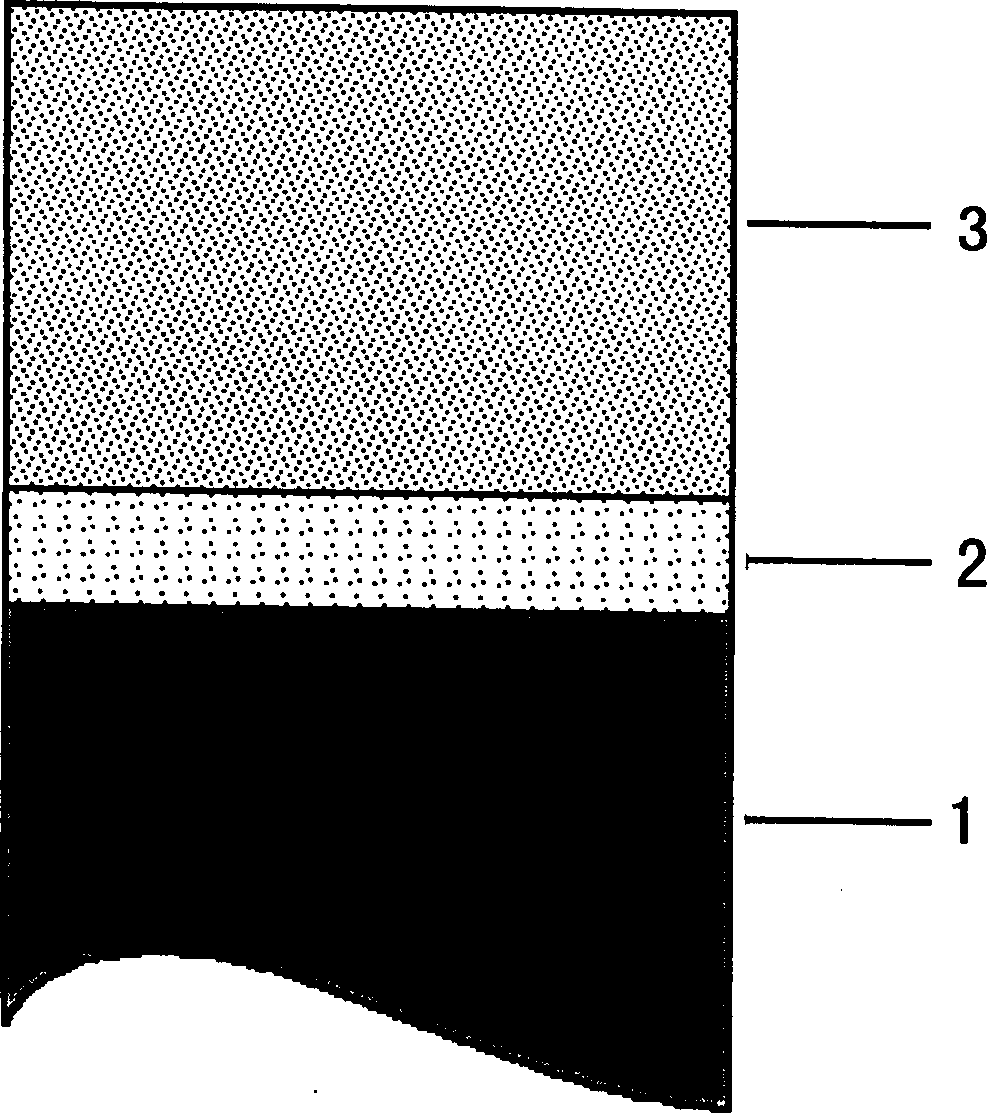

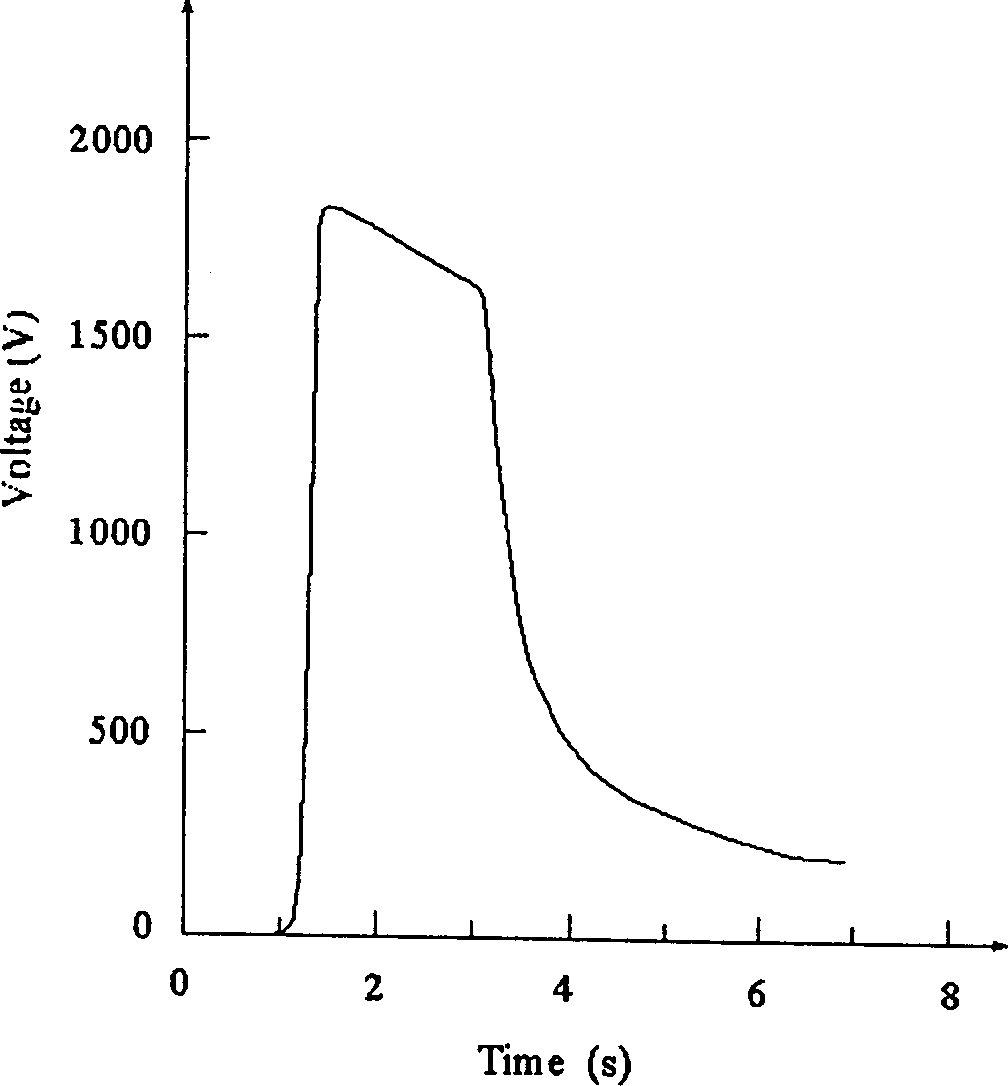

[0017] Example 1. Polycarbonate was dissolved in 1,2-dichloroethane solvent to prepare a film-forming agent solution. The mass concentration of the solution was 10%. Titanium phthalocyanine, p-diethylaminobenzaldehyde diphenyl The hydrazone and the film-forming agent solution are mixed in a mass ratio of 1:40:6000, put into a glass container, and reinforced glass balls with a diameter of 4 mm are added in a ratio of mixture: glass ball mass ratio of 1:2, and dispersed with a ball mill for 24 The coating solution was prepared within hours, and the size of the phthalocyanine oxyphthalide aggregates dispersed in the solution was 5-20 nm. figure 1 STM photographs of phthalocyanine oxyphthalide aggregates are shown. The coating solution was coated on the aluminum plate substrate pre-coated with pyruvate by the blade coating method, and dried at 90° C. for 1 hour. objects have charge transfer properties, figure 2 It is a schematic diagram of the structure of the device, in the fi...

Embodiment 2

[0018] Embodiment 2, polystyrene is dissolved in tetrahydrofuran solvent, prepare film-forming agent solution, its solution mass concentration is 5%, and the solution of vanadyl phthalocyanine, p-diethylaminobenzaldehyde diphenylhydrazone and film-forming agent solution is pressed according to After mixing in a mass ratio of 1:100:4000, the mixture was put into a glass container and dispersed with an ultrasonic generator for 24 hours to prepare a coating liquid. The coating solution was coated on an aluminum plate substrate pre-coated with halloysite by a blade coating method, and dried at 60° C. for 3 hours to prepare a single-layer organic photoconductive device with a thickness of 40 m.

Embodiment 3

[0019] Embodiment 3, dissolve polyvinyl butyral in cyclohexanone, prepare film-forming agent solution, and its solution mass concentration is 7%, mix titanium phthalocyanine, p-diethylaminobenzaldehyde diphenylhydrazone and film-forming agent After the solution is mixed in a mass ratio of 1:70:8000, it is put into a glass container, and reinforced glass balls with a diameter of 1 mm are added in a ratio of mixture: glass ball mass ratio of 1:2, and dispersed with a ball mill for 24 hours to make the solution. coating liquid. The coating solution was coated on an aluminum plate substrate pre-coated with halloysite by knife coating, and dried at 80° C. for 2 hours to prepare a single-layer organic photoconductive device with a thickness of 20 m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com