Prepn process of nano level osteoid apatite crystal

A bone-like apatite, nano-scale technology, applied in chemical instruments and methods, prostheses, phosphorus compounds, etc., can solve the problems of strong irritating odor of ammonia water, harmful to human body, and large environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

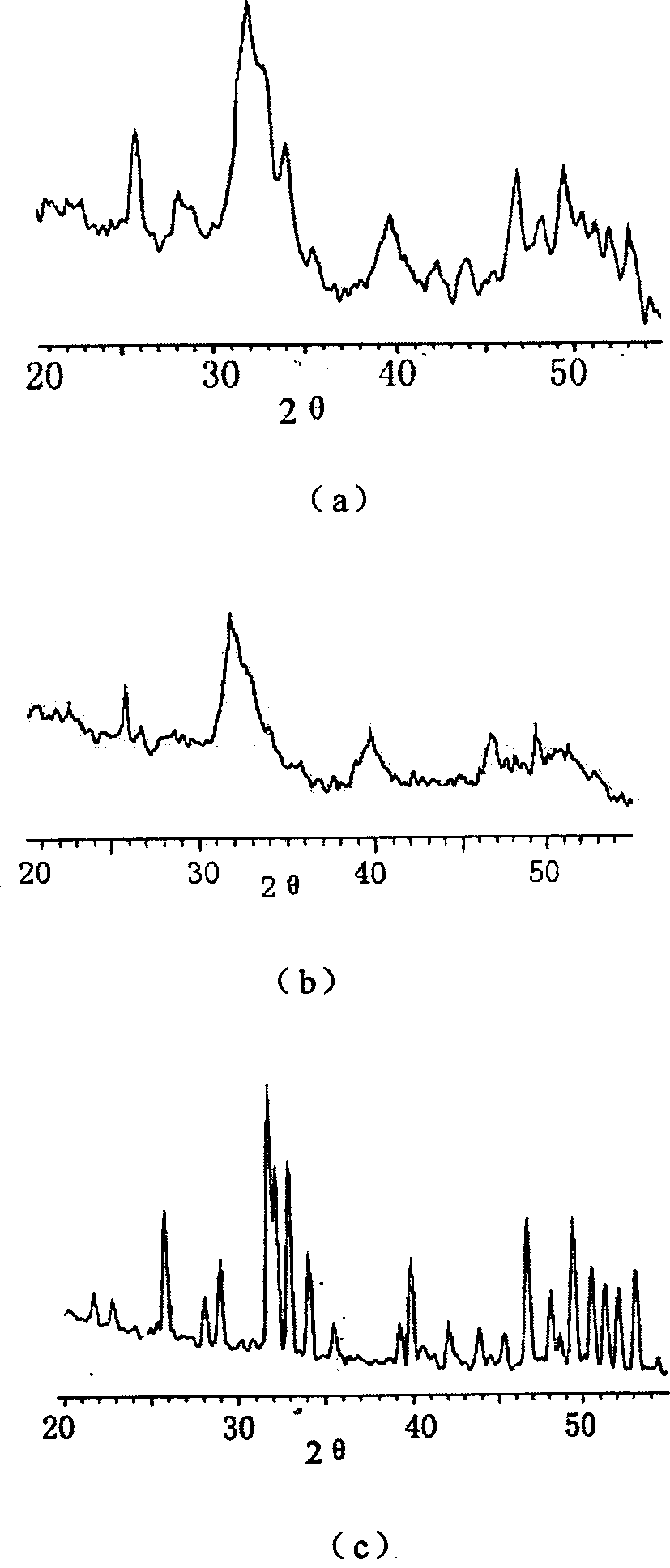

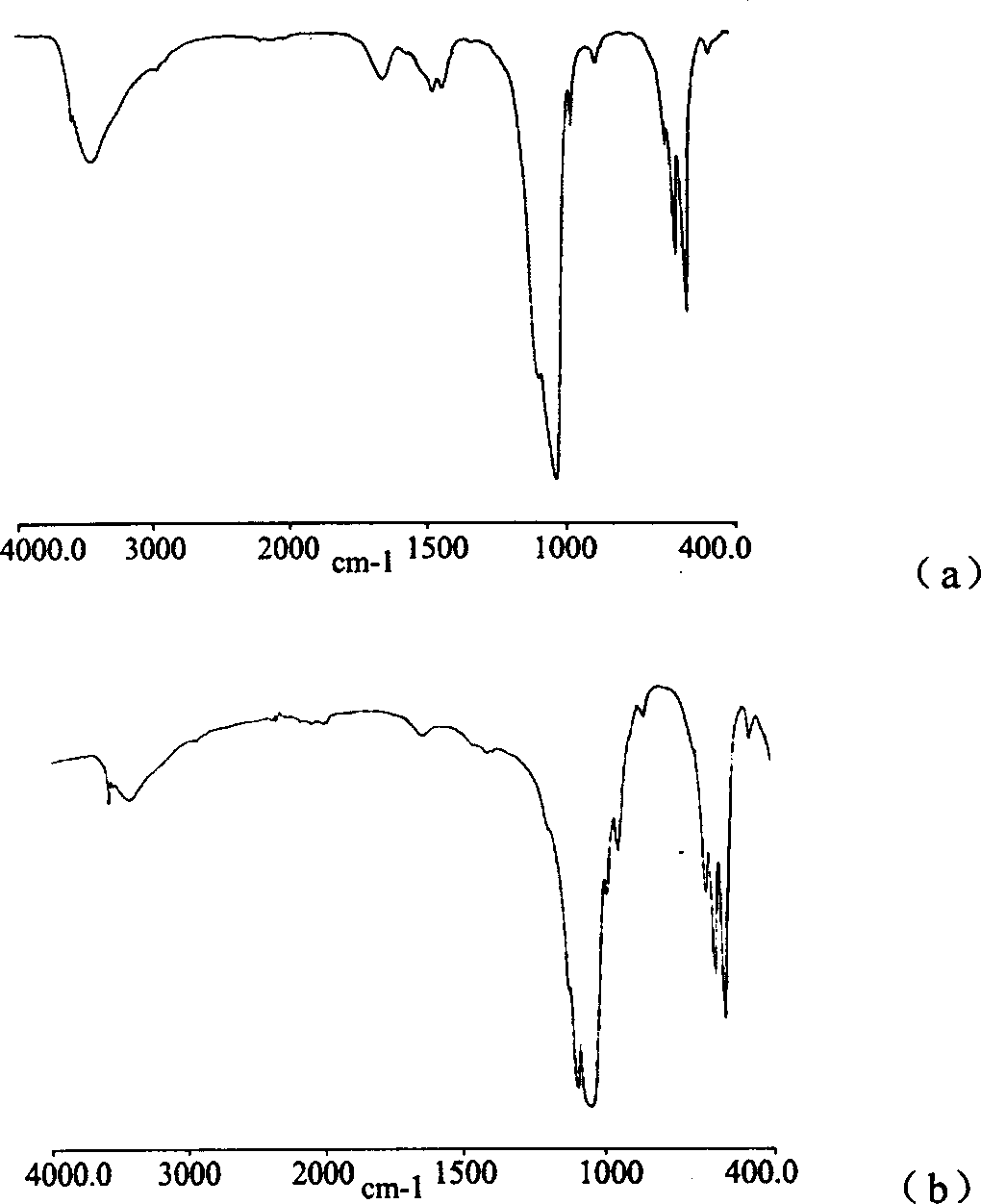

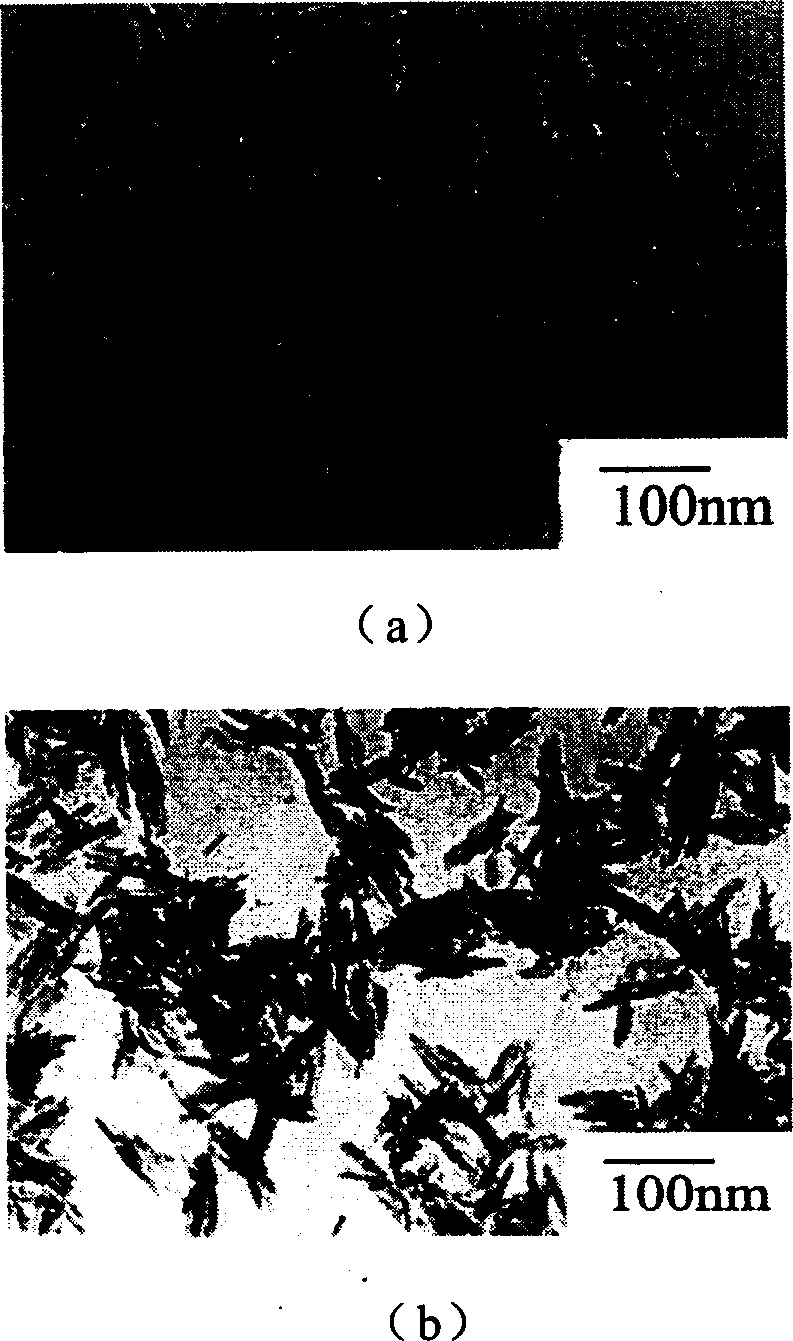

[0015] Get 12 grams of sodium phosphate (analytically pure) and dissolve it in 1000 milliliters of deionized water to form a solution, and then dissolve 20 grams of calcium nitrate (analytical pure) in 30 grams of acetamide while heating and keeping it at 70 ° C and constantly stirring. (Analytical pure) The resulting solution was slowly added dropwise to the sodium phosphate solution. After dropping, the mixture was stirred and reacted for 2 hours while maintaining the same temperature, and aged for 24 hours at room temperature. After centrifugation, the supernatant was discarded, and then washed with water for 3 times to obtain a slurry of nano-scale bone-like apatite crystal deposits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com