Slide gate nozzle brick utilized in metallurgic cast and prepn. thereof

A sliding nozzle and metallurgical technology, used in foundry equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unsatisfactory comprehensive performance and high cost, and achieve excellent high temperature wear resistance, excellent performance, and improved adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] According to the example table (Table 1), take the processed raw materials and binder respectively, fully mix them evenly in the kneader, press the nozzle and the slide plate respectively with a brick press, and dry the adobe at room temperature -300°C, then reduce the Or in a neutral atmosphere, heat treatment at 1000°C / 16h and 500°C / 16h respectively to obtain a solid solution sliding nozzle brick with metal (aluminum)-oxygen-nitrogen, and then impregnated with asphalt, and the sliding brick is finally smoothed, hooped and assembled , Coated surface.

[0015] It is also possible to replace metal particles with metal fibers ranging from 0.2-0.5mm in diameter and 3-10mm in length at 0.5-3% respectively;

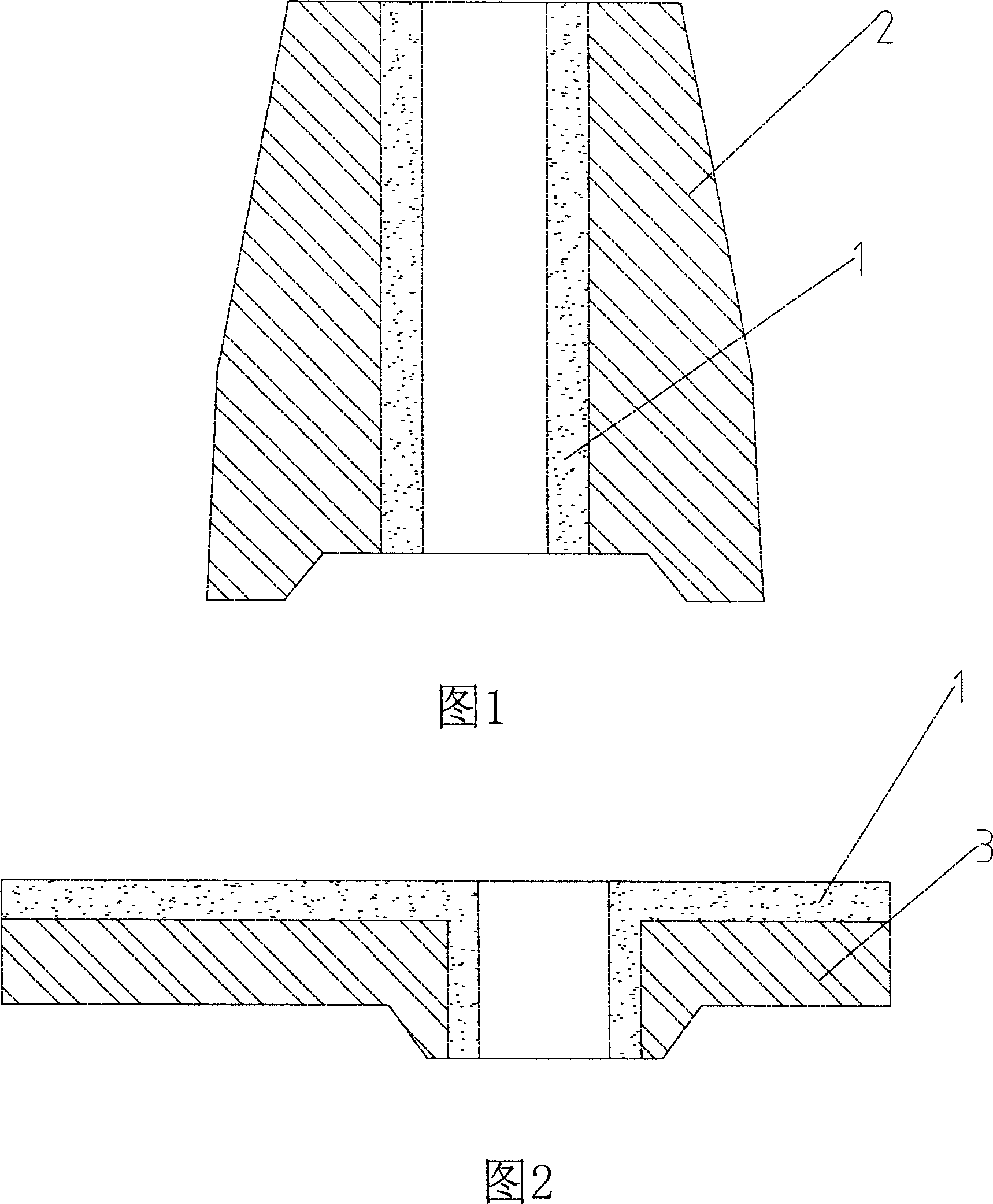

[0016] The raw materials of the above examples can also be used as the working surface layer material of the sliding nozzle brick, the thickness of the working surface layer is 15%, 30% and 50% of the thickness of the sliding nozzle brick, and the bottom layer is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com