Method and equipment for raising speed of electronic cyclotron resonance chemical vapor deposition

An electron cyclotron resonance and chemical vapor deposition technology, applied in the field of plasma, can solve the problems of poor magnetic field distribution uniformity, low film deposition speed, complicated control, etc., and achieve the effects of low manufacturing cost, improved film deposition speed, and small device volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

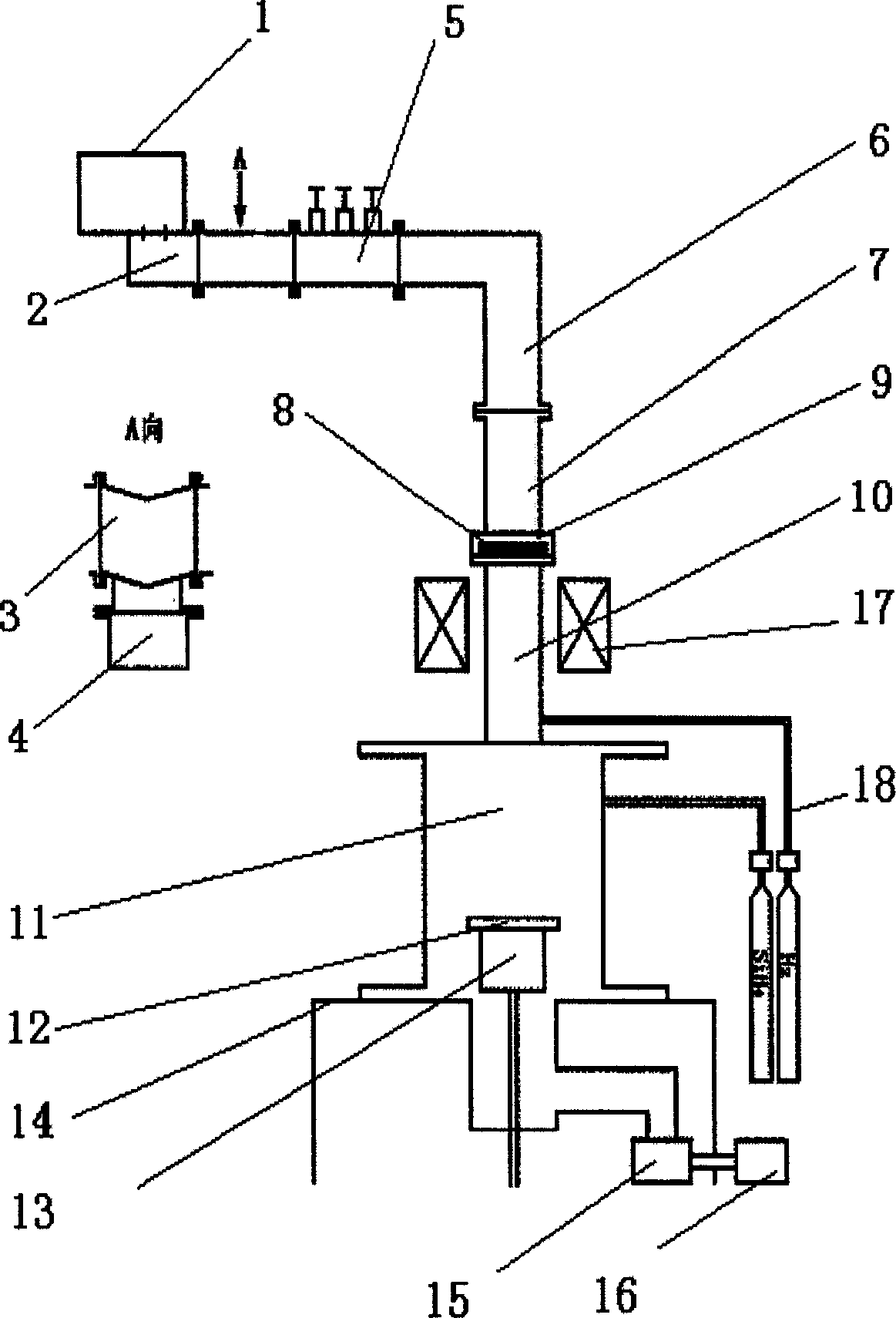

[0024]Example 1: The experimental condition is that the system is evacuated to 1×10 -3 Pa, hydrogen gas is passed into the resonance cavity 10 with a flow rate of 20 sccm, the air pressure is adjusted to 0.5 Pa, a current of 137A is passed into the magnetic field coil 17, and the actual output power of the microwave source 1 is 500W. Electron cyclotron resonance plasma can be generated in the resonant cavity 10 and the deposition chamber 11 under the joint action of the microwave and the coil magnetic field.

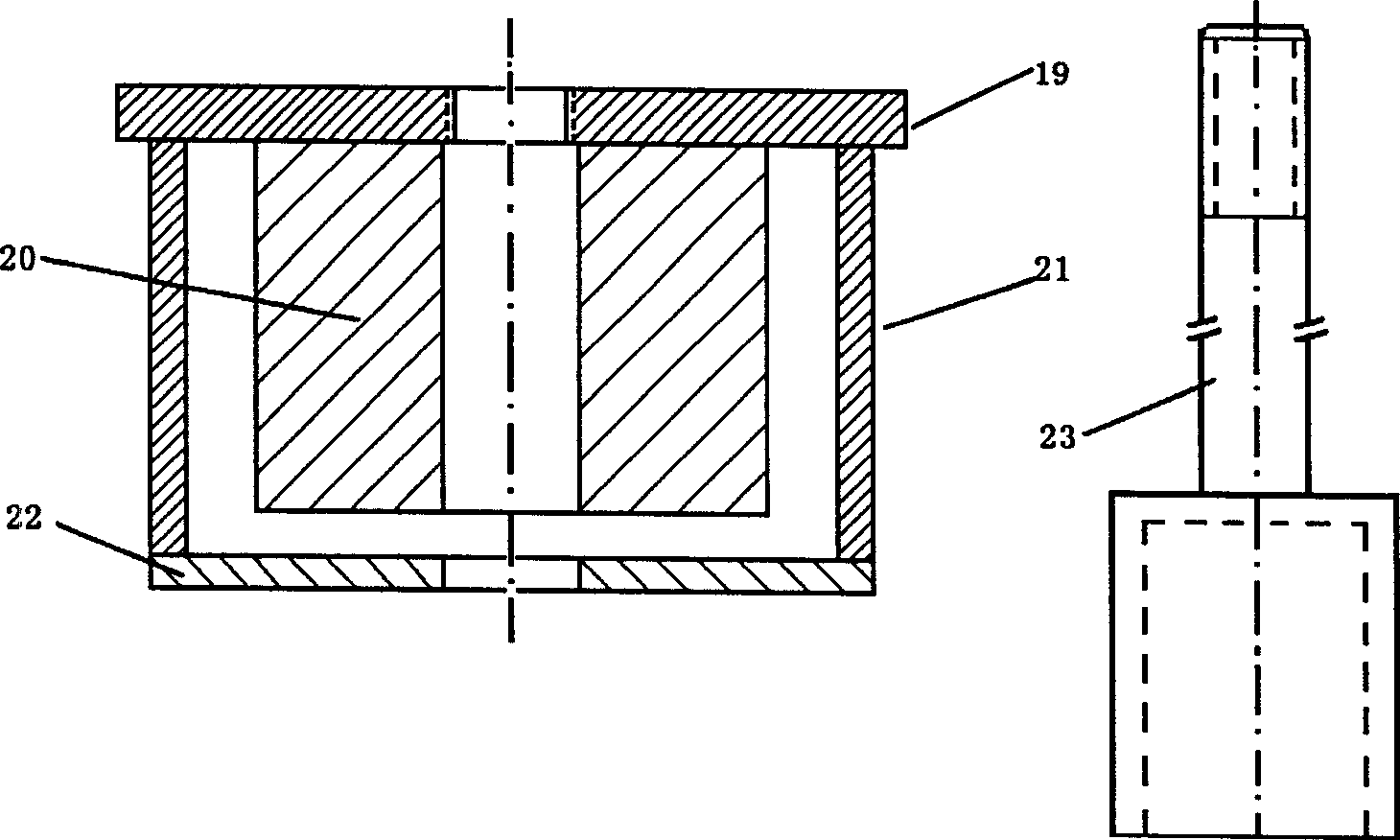

[0025] image 3 and Figure 4 They are the plasma photo when the single coil magnetic field 17 is used and the plasma photo when the single coil 17 magnetic field is combined with the permanent magnet unit 13 magnetic field. The plasma in the single-coil magnetic field is divergent in the vacuum deposition chamber 11; the plasma in the combination of the magnetic field of the single coil 17 and the magnetic field of the permanent magnet 13 unit is divergent in the vacu...

example 2

[0026] Example 2: Put a clean glass sheet with a size of 20mm×20mm×1mm on the sample stage 12, and the system is vacuumed to 1×10 -3 Pa, heat the sample to 280°C, feed hydrogen gas into the resonant cavity 10 with a flow rate of 20 sccm, feed silane into the deposition chamber 11 with a flow rate of 7 sccm, adjust the total air pressure to 0.5 Pa, feed a current of 137A into the magnetic field coil 17, and microwave The actual output power of source 1 is 500W. Under the joint action of microwave and coil magnetic field, electron cyclotron resonance plasma is generated in the resonant cavity 10 and the deposition chamber 11, and the amorphous silicon film is deposited on the glass sheet. The deposition rate of the amorphous silicon film is 5.2 Å / s when the magnetic field of the single coil 17 is used; the deposition rate of the amorphous silicon film is 12.2 Å / s when the magnetic field of the single coil 17 is combined with the magnetic field of the permanent magnet unit 13 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com