Benzene selective hydrogenation carried ruthenium based catalyst and its preparation

A technology for selective hydrogenation and ruthenium catalyst, applied in the chemical industry, can solve the problems of increasing the difficulty of industrial operation, energy consumption, unsuitability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

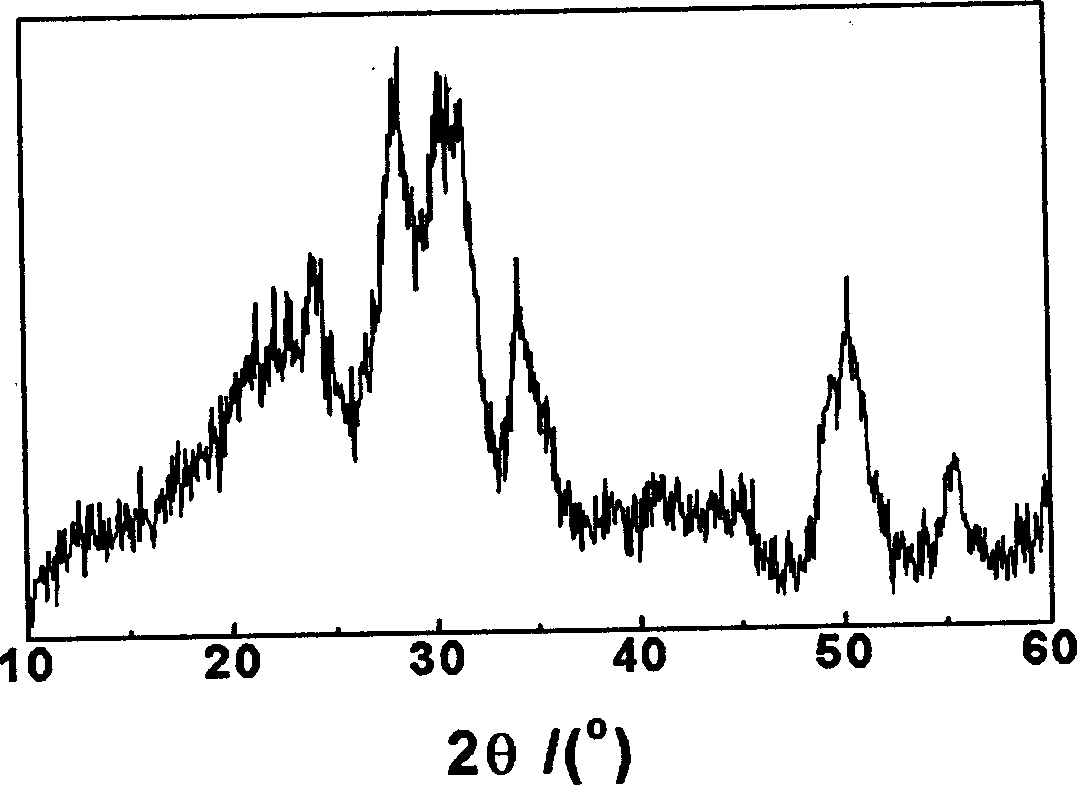

Image

Examples

Embodiment 2

[0017] Put 40mL of 2.0mol / L ZrOCl 2 The solution and 40mL of 3.0mol / L ammonia were added dropwise to RuCl at 50℃ with constant temperature stirring. 3 In solution (containing Ru1.6×10 -4 g / mL), the dropping rate is 1.0ml / min. After the addition is complete, continue to stir at constant temperature for 40 minutes, leave it at room temperature overnight, and centrifuge to wash it until there is no chloride ion. The reduction treatment of the catalyst is carried out in an autoclave. The washed catalyst, 100mL water, 4.0g ZnSO 4 ·7H 2 O was put into a 500 mL autoclave and replaced with hydrogen 3 times to remove the air in the autoclave. The reduction treatment conditions are as follows: the hydrogen pressure is 4.28MPa, the stirring speed is 1000r / min, the reduction temperature is 180°C, and the reduction time is 40min. Example 2: Ru-Zn / ZrO 2 ·XH 2 Preparation of O catalyst

[0018] ZrOCl 2 The solution and ammonia are added dropwise to RuCl with constant temperature stirring at 50℃ ...

Embodiment 3

[0020] Slowly drop a sufficient amount of ammonia (6M) into an appropriate amount of RuCl stirred at a constant temperature of 50°C 3 In the mixed solution with aluminum nitrate, the pH of the final mixed solution is 9.2. After the addition is completed, continue to stir and hydrolyze for 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com