Preparation method of concentration floating agent for copper and iron

A copper iron spirit and flotation agent technology, applied in flotation, solid separation and other directions, can solve the problems of serious pollution, high production cost, poor production process conditions, etc., and achieve the goal of reducing production cost, reducing pollution and improving production conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

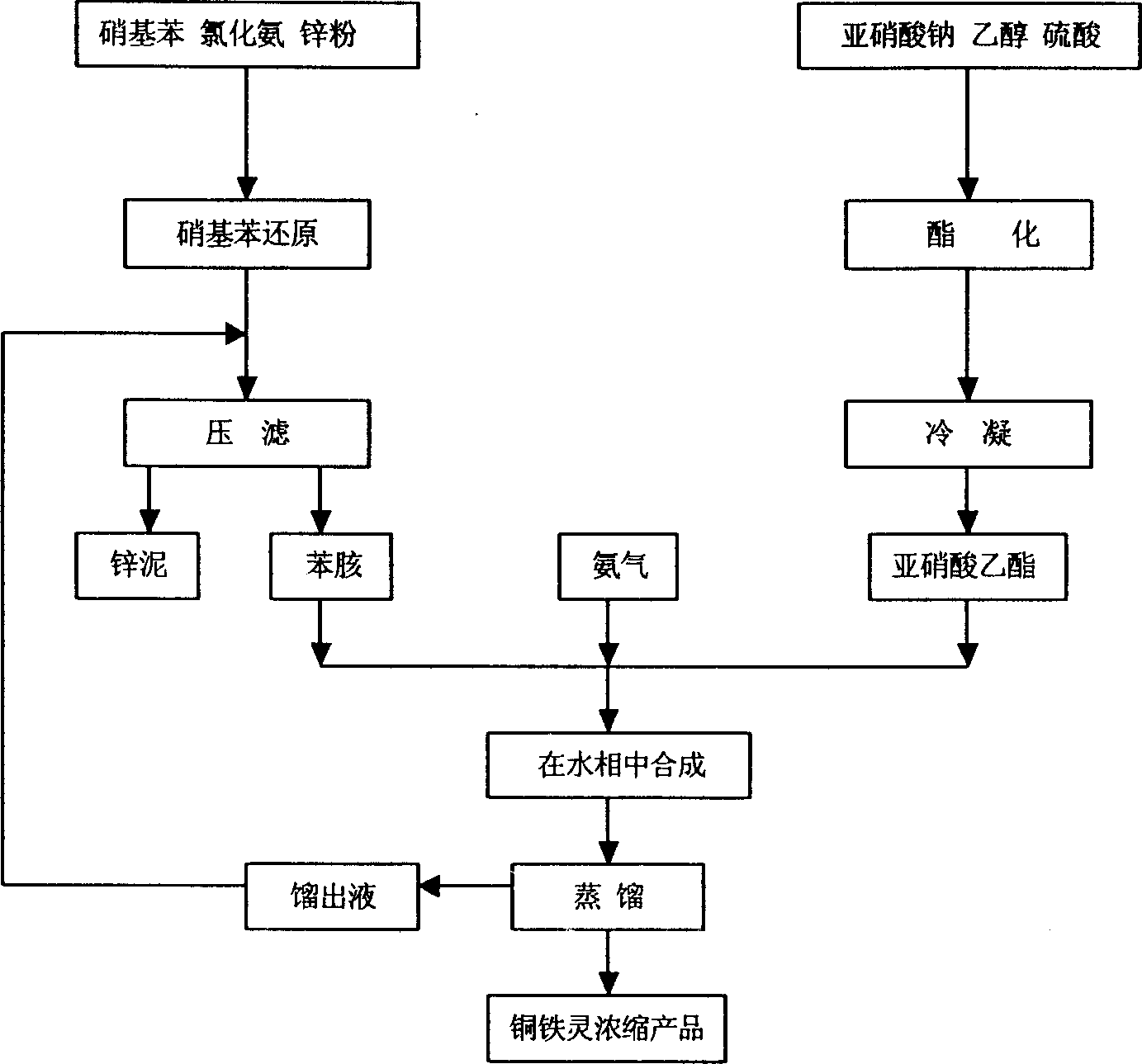

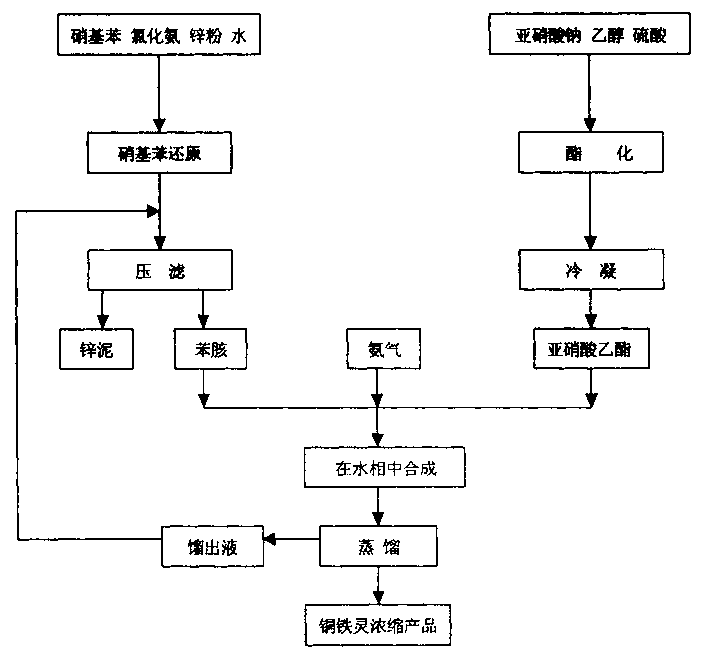

Method used

Image

Examples

Embodiment 1

[0015] Nitrobenzene reduction was performed in 2000 ml three-stem flasks. Add 800ml of water, 75g of ammonium chloride, and 126ml of nitrobenzene to the three-stem bottle in sequence, stir well and mix well. Zinc powder was added at 15°C. 180 g of zinc powder were added to the mixture over 20 minutes and the temperature was allowed to rise to 65°C. Continue to stir for half an hour after adding the zinc powder. Then vacuum filter the reaction product with a large Buchner funnel, and wash the filtrate twice with 200ml warm water (65° C.), the filtrate contains β-benzene, and the filter cake is mainly zinc oxide.

[0016] Synthesis of copper iron was carried out in 1000 ml three-stem bottles. Put the β-arginine solution in a three-stem bottle, and immerse the three-stem bottle in ice-salt water to cool down. After the temperature in the bottle is cooled to about 10°C, pass ammonia gas into it, and then slowly add 120ml of ethyl nitrite , During this process, continue to maint...

Embodiment 2

[0019] Implementation steps are the same as in Example 1. Among them, 126g of nitrobenzene, 180g of zinc powder, 75g of ammonium chloride, and 800ml of water, the initial reaction temperature for the preparation of β-phenylene is 10°C, and the maximum reaction temperature is 70°C. The initial temperature for synthesizing cupferrin was 2°C, the highest reaction temperature was 10°C, and the reaction time was 90 minutes. The cupferrin aqueous solution was distilled to finally obtain an aqueous solution with a weight of 516 g, and the content of cupferrin was 20.84%.

Embodiment 3

[0021] Implementation steps are the same as in Example 1. Among them, 126g of nitrobenzene, 150g of zinc powder, 75g of ammonium chloride, and 800ml of water, the initial reaction temperature for the preparation of β-phenylene is 15°C, and the maximum reaction temperature is 68°C. The initial temperature for synthesizing cupferrin was 5°C, the highest reaction temperature was 15°C, and the reaction time was 80 minutes. The cupferrin aqueous solution was distilled to finally obtain an aqueous solution with a weight of 498 g, and the content of cupferrin was 19.87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com