Technique for welding car axle housing made by punching medium heavy steel plates

A welding process and thick steel plate technology, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of easy generation of nitrogen pores, strength reduction, and spatter, so as to ensure welding quality, increase welding strength, and improve bonding intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

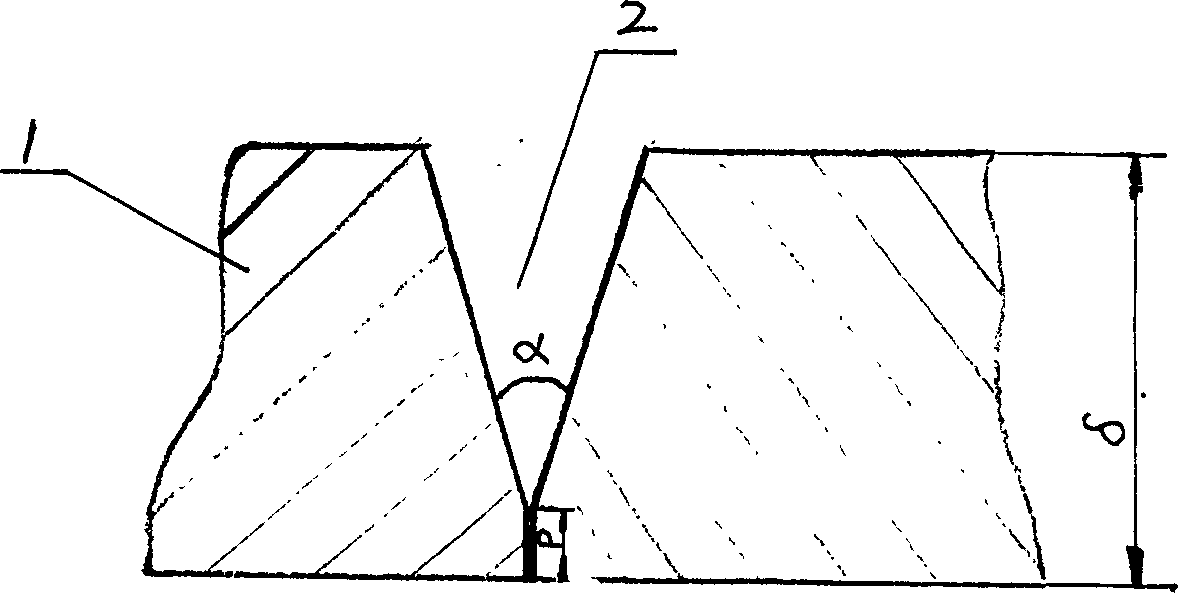

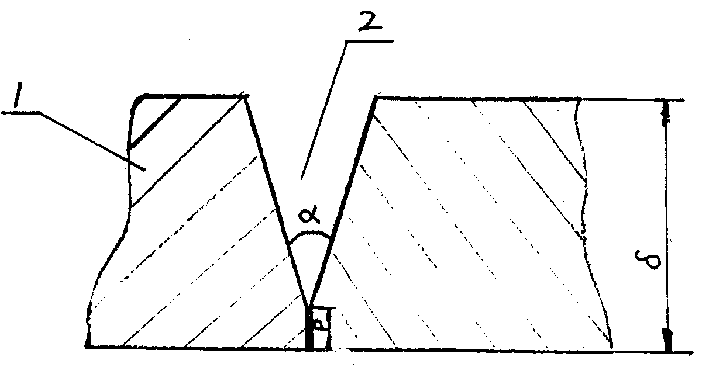

[0026] Example 1: When performing gas shielded welding on medium-thick steel stamped automobile axle housings, the thickness δ of the steel plate 1 is 12mm, and the butt joint steel plate 1 has a double-sided groove 2 in a Y shape, and the groove angle α is 6°, blunt The side height P is 0mm, the shielding gas is carbon dioxide, and the process parameters are: the diameter of the welding wire is 1.6mm, the welding voltage is 32V, the welding current is 500A, the welding speed is 0.4m / min, the welding tip height is 20mm, and the number of welding times is For one pass, the gas flow rate is 18L / min, the eccentricity is 8mm, the welding power source is DC reverse connection, the welding wire direction is reverse, the welding method is boat welding, and the penetration rate reaches 100%.

Embodiment 2

[0027] Embodiment 2: When performing gas shielded welding, when the thickness δ of the butt steel plate 1 is 20mm, the butt steel plate has a double-sided groove 2 in a Y shape, the groove angle α is 12°, and the shielding gas is argon and carbon dioxide mixed gas. The ratio is 4:1, and its process parameters are: blunt edge height P is 4mm, welding wire diameter is 2.0mm, welding voltage is 36V, welding current is 600A, welding speed is 0.8m / min, welding tip height is 25mm, welding The number of passes is one, the gas flow rate is 25L / min, the welding power supply is DC reversed, the direction of the welding wire is reversed, the welding method is flat welding, the design penetration rate is 66%, and the penetration rate reaches the standard.

Embodiment 3

[0028] Embodiment 3: When performing gas shielded welding, when the thickness δ of the butt steel plate 1 is 16mm, the butt steel plate 1 has a double-sided groove 2 in a Y shape, the groove angle α is 10°, and the shielding gas is carbon dioxide gas. The parameters are: the blunt edge height P is 3mm, the welding wire diameter is 1.6mm, the welding voltage is 34V, the welding current is 550A, the welding speed is 0.5m / min, the welding tip height is 20mm, the number of welding times is two times, and the gas flow rate is 22mL / min, the welding power supply is DC reversed, the direction of the welding wire is reversed, the welding method is boat welding, and the penetration rate reaches 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com