Semi-automatic control method of feedback ventilation temperature in producing aerobic compost

A technology of temperature feedback and aerobic composting, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of high labor intensity, the temperature of the lower layer cannot reach 55°C, and the poor effect of pathogenic bacteria, etc. The effect of temperature control time, shortening the processing cycle, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

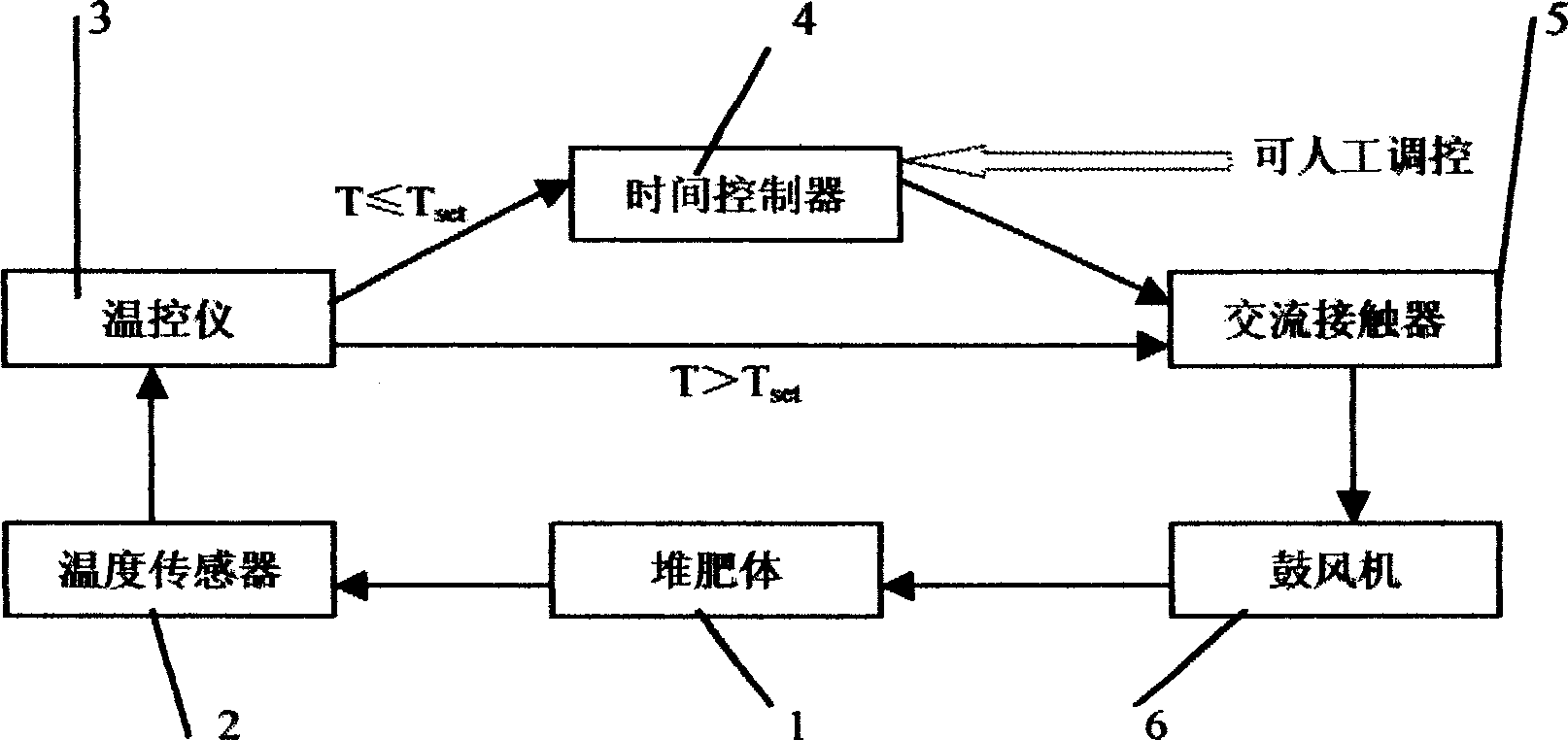

[0006] The invention relates to a semi-automatic control method for temperature feedback ventilation of aerobic composting. Composting is a method for processing organic solid waste. During the treatment process, the temperature control and ventilation adopts the semi-automatic control technology of temperature feedback ventilation combining automatic and manual. , That is, in the first stage, control the temperature of the center of the compost body at 70°C to 75°C, which can kill pathogenic bacteria; Good; in the later stage of composting, artificially adjusting the opening and closing time of the fan can still keep the temperature of the compost at 55°C-60°C. Its control process is to detect compost body 1 central temperature by temperature sensor 2 (as figure 1 As shown), the temperature controller 3 sends the control signal to the AC contactor 5 to control its on-off; decide whether the blower 6 is blowing air, when the temperature is kept at the predetermined temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com