Silicofluoride containing acrylic copolyresin emulsion and paint

A technology of silicon copolymer resin and acrylic acid, applied in the direction of coating, etc., can solve the difficult problems of hydrophilic monomer vinyl ether compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

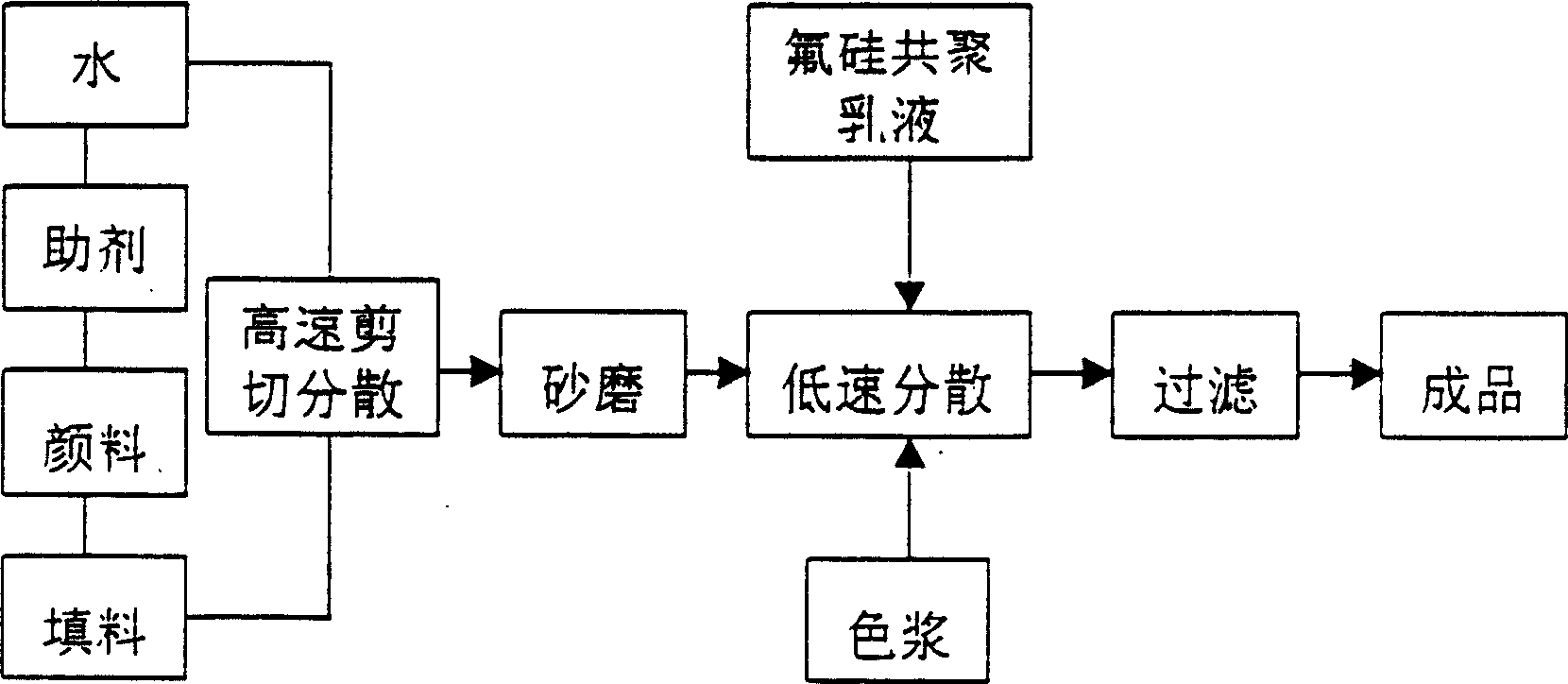

Method used

Image

Examples

Embodiment Construction

[0032] Illustrate the present invention with the following examples, but do not limit the examples of the invention: (1) Instruments and manufacturing techniques used in Examples 1 to 6

[0033] According to the components listed in Table 1, 70% of the solvent and deionized water, compound emulsifier, initiator and all acrylate mixtures are added at room temperature in a container equipped with a high-shear mixer, at a speed of 1000r / min , pre-emulsified for 0.5h. The obtained emulsion is placed in a dropping funnel to pass through nitrogen to remove oxygen for use.

[0034] In another four-necked flask equipped with agitator, condenser, thermometer and dropping funnel, add another 30% solvent and deionized water emulsifier and initiator, nitrogen deoxygenation, heated to 80 ℃, after 15 minutes of heat preservation, take 2 hours, control the temperature at 80 ℃, add the monomer pre-emulsion dropwise under stirring, after the pre-emulsion is dripped, then add the organosilane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com