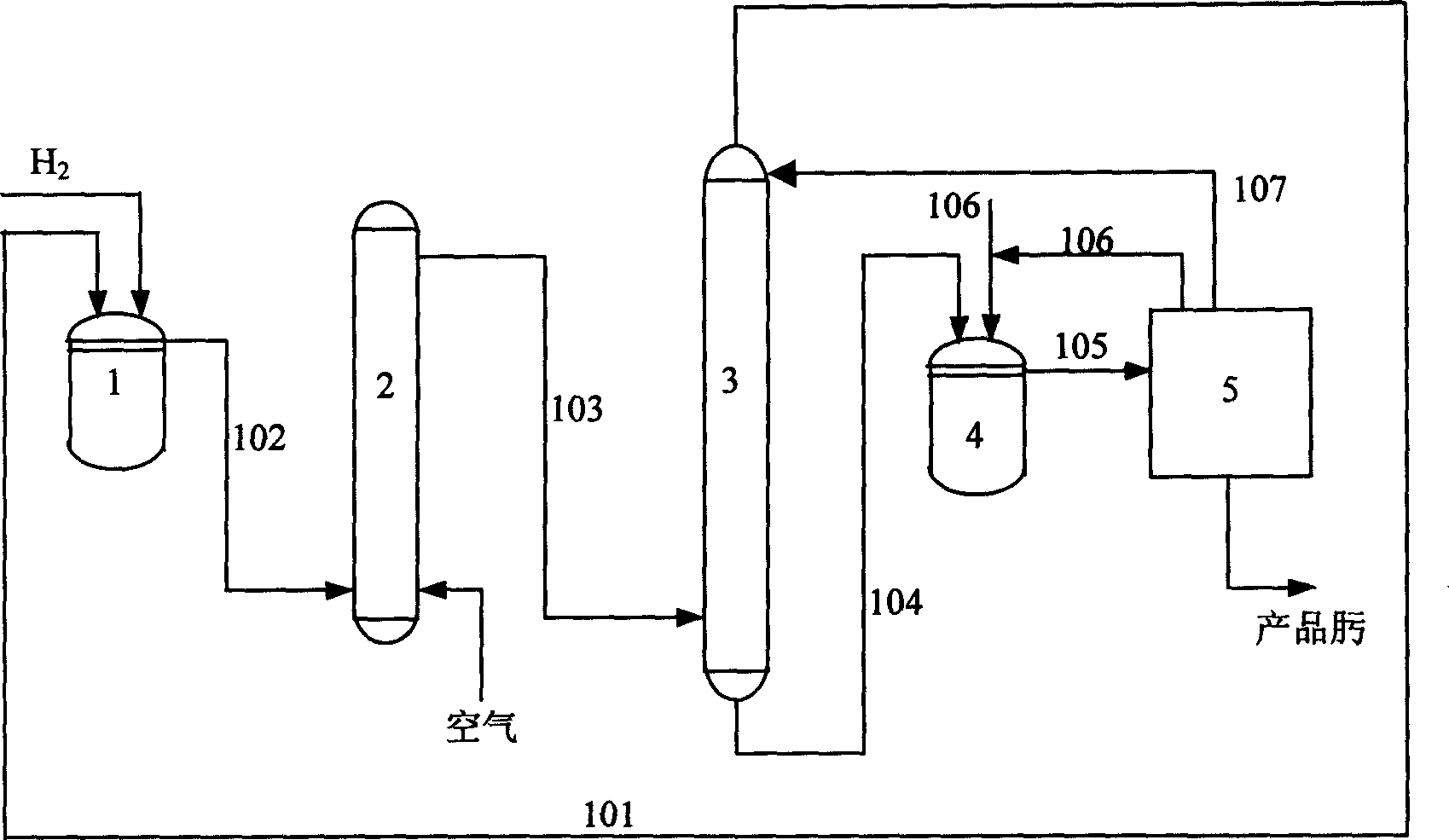

Procedure of producing cyclohexanone-oxime by preparation of hydrogen peroxide by combined anthraquinone process

A technology of H2O2 and cyclohexanone oxime, which is applied in oxime preparation, organic chemistry and other directions, can solve problems such as difficulty in storage and transportation, and achieve the effect of simplifying the process and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] C 9 The content of aromatics is 68.4% (mass), the content of trioctyl phosphate is 22.8% (mass), and the content of anthraquinone is 900ml of anthraquinone working solution of 8.8% (mass) for catalytic hydrogenation for 2 hours, and then the catalyst is centrifuged. Oxidize the separated hydrogenated liquid with oxygen at 40°C and 0.30MPa for 0.5 hours to generate H 2 o 2 working fluid. Use 70ml of 33.5% (mass) aqueous methanol to extract the H in the oxidation solution 2 o 2 , the extract H 2 o 2 The concentration is 9.9% (mass). Add 1.50g of titanium-silicon molecular sieve TS-1, 15.20g of cyclohexanone, and 22.90g of 25% (mass) ammonia water into a 250ml reaction kettle, mechanically stir at a speed of 800 rpm and heat up to 70°C, and wait for the temperature to stabilize , 70ml of extract solution was continuously added to the reaction kettle within 4 hours through a metering pump, and reacted for another 1 hour after the feeding was completed, then cooled do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com