Quartz metal halide lamps with high lumen output

A metal halide, light output technology, applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of not improving the light output, etc., to improve lamp efficiency, reduce energy loss, and heat conduction loss Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

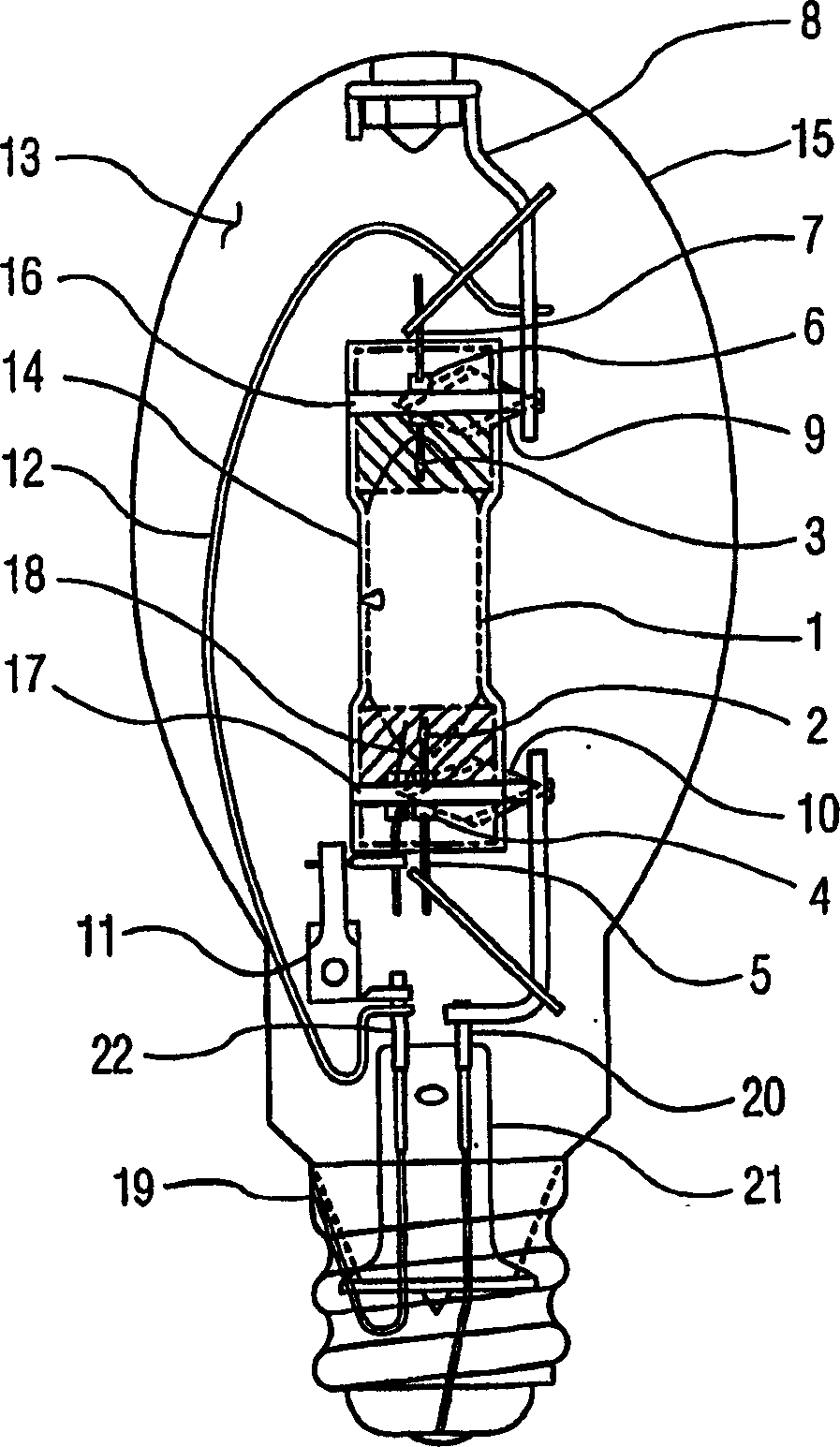

[0016] According to the present invention, referring to figure 1 , mark 1 denotes a quartz glass discharge vessel or arc tube filled with a filling including mercury; sodium halide; and one or more metals such as scandium, cesium, calcium, zinc, cadmium, and an inert gas such as argon , barium, mercury, gallium, indium, thallium, germanium, tin, thorium, selenium and tellurium and other halides. In general, iodides of these metals are preferred, although bromides and in some cases chlorides can also be used. The arc tube may contain one or more of sodium iodide, sodium bromide or sodium chloride, all of which are known in the art. According to the present invention, including silicon nitride (Si 3 N 4 ) coating 14 is deposited on the outer surface of the arc tube 1, preferably by chemical vapor deposition (CVD) before the lamp components are assembled into the lamp. Preferably, the arc tube is coated with about 30 nanometers to 200 nanometers of silicon nitride.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com