Method of establishing nano organic silane dressing layer on hydroxy apatite surfac

A hydroxyapatite, nano-organic technology, applied in medical science, prosthesis and other directions, can solve the problems of difficult to control the thickness of the coating layer, fast reaction speed, fast strength loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

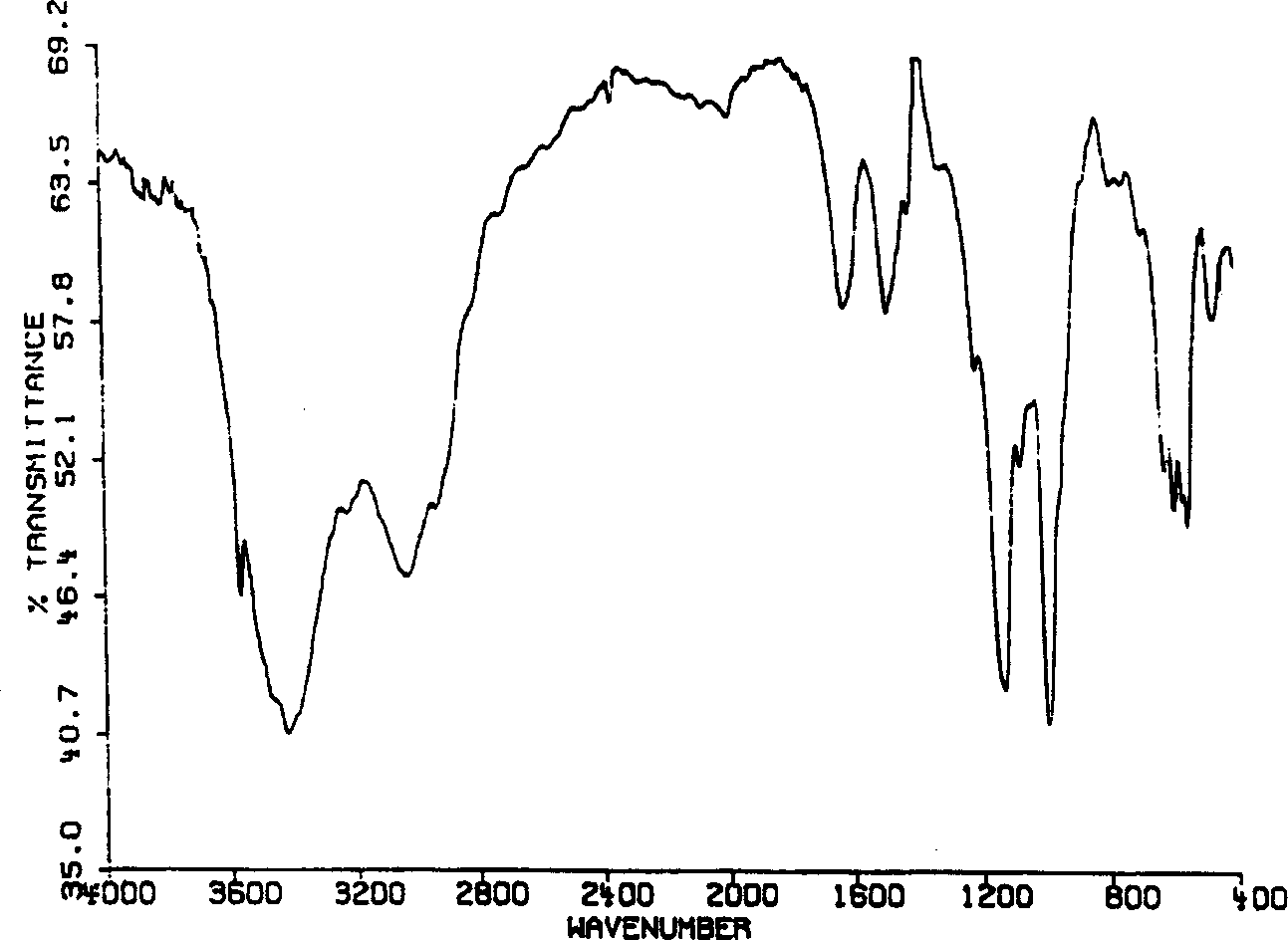

Image

Examples

example 1

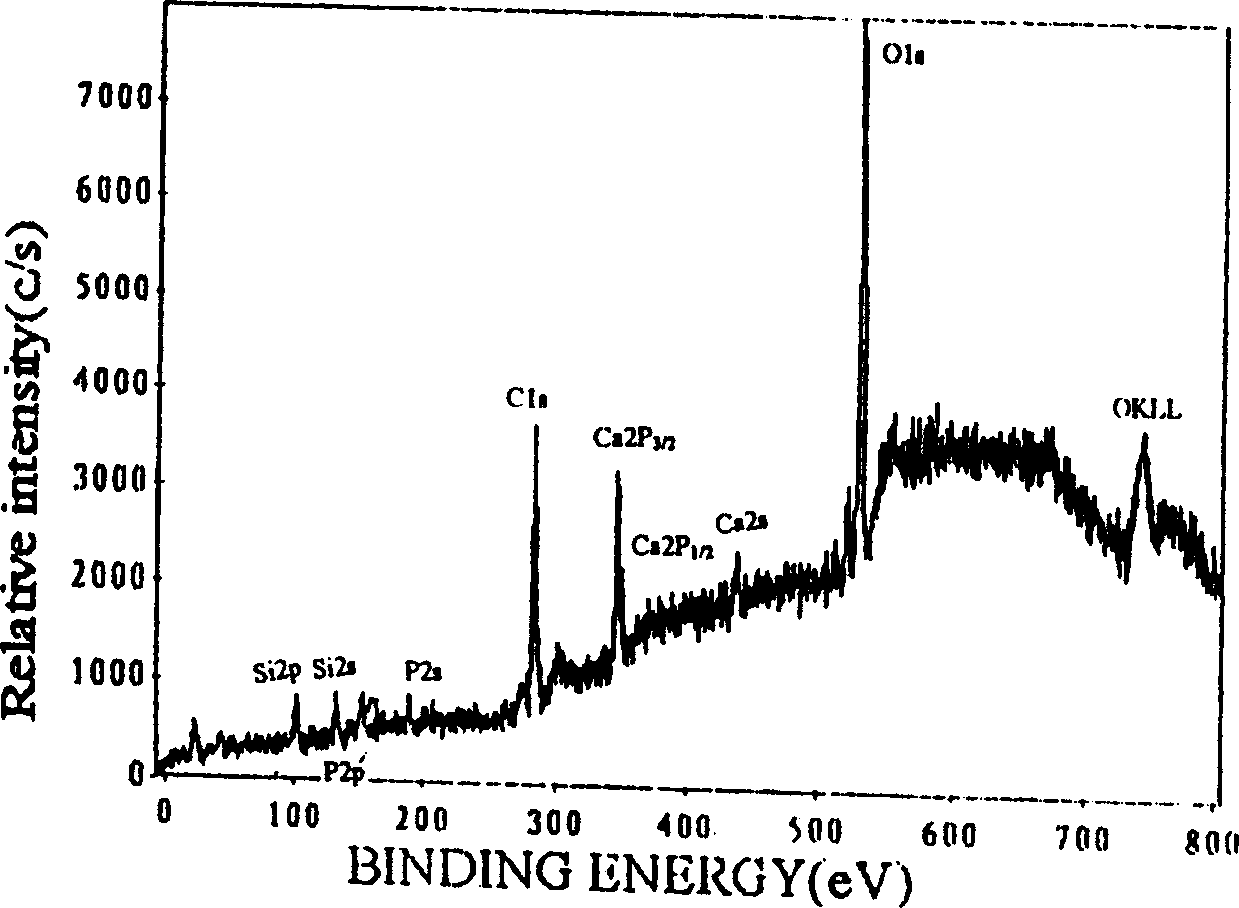

[0018] Example 1. Add 100 parts of hydroxyapatite micropowder (15-25 μm) into dry toluene under magnetic stirring, reflux under nitrogen protection for 0.5 hours, then add 2 parts of γ-aminopropyltriethoxysilane dropwise, and continue to reflux React for 12 hours; cool and centrifuge the reaction mixture, wash the precipitate three times with chloroform and absolute ethanol successively, dry at room temperature for 8 hours, and then dry in vacuum at 50° C. for 24 hours. According to the X-photoelectron spectroscopy (XPS) results, the thickness of the silane-modified layer is 1.8nm.

[0019] The calculation method is as follows:

[0020] Calcium atomic percentage (Ca Atom%) on the surface of unmodified hydroxyapatite: 18.6%, and the (maximum) thickness Th of the hydroxyapatite layer scanned by XPS at this time max = 10nm; and the calcium atomic percentage Ca Atom% on the surface of γ-aminopropyl triethoxysilane modified hydroxyapatite scanned by XPS is 15.2%, and the thickness...

example 2

[0021] Example 2. Add 100 parts of hydroxyapatite micropowder (15 to 25 μm) into dry N, N-dimethylformamide under magnetic stirring, reflux under nitrogen protection for 0.5 hour, then drop 2 parts of γ-(methyl Acryloyloxy)propyltrimethoxysilane, continue the reflux reaction for 13 hours; cool and centrifuge the reaction mixture, wash the precipitate with chloroform and absolute ethanol three times in turn, dry at room temperature for 8 hours, and then vacuum dry at 50°C 24 hours. According to the X-photoelectron spectroscopy (XPS) results, the thickness of the silane-modified layer was obtained by the same method as 2.7 nm.

example 3

[0022] Example 3. Add 100 parts of hydroxyapatite micropowder (15 to 25 μm) into dry N, N-dimethylformamide under magnetic stirring, reflux under nitrogen protection for 0.5 hours, then dropwise add 1 part of γ-(methyl Acryloyloxy)propyltrimethoxysilane, continue the reflux reaction for 14 hours; cool and centrifuge the reaction mixture, wash the precipitate with chloroform and absolute ethanol three times in turn, dry at room temperature for 8 hours, and then vacuum dry at 50°C 24 hours. According to the X-photoelectron spectroscopy (XPS) results, the thickness of the silane-modified layer obtained by the above method was 1.6 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com