Terminal with ruthenium layer and component with the same terminal

A technology of terminals and parts, which is applied in the field of terminals and parts with the terminals, can solve problems such as unexplained solutions, unspoken gold layer peeling problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

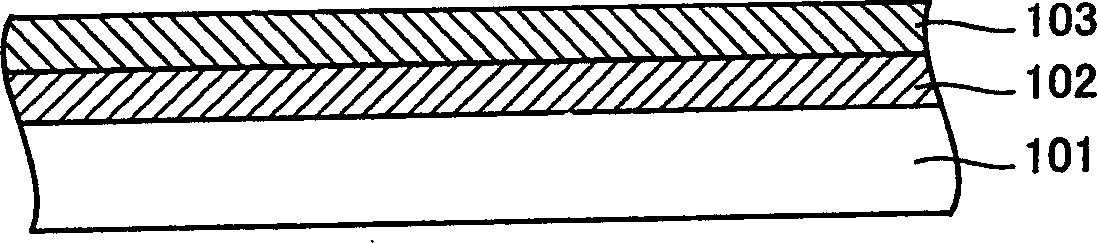

[0051] This embodiment is a connector terminal in which a ruthenium layer and a gold layer as a surface metal layer are sequentially formed on a conductive substrate. Refer to the following figure 1 Describe it.

[0052] First, as the conductive substrate 101, a strip-shaped nickel having a thickness of 0.1 mm was press-worked into a connector shape, and the continuous connector terminal shape was cut into a length of 70 mm. After cutting, it was washed with 50 g / l of an active agent (trade name: ACE CLEAN 30, manufactured by Okuno Pharmaceutical Co., Ltd.) at 53° C. for 3 minutes to perform a degreasing treatment. Then, after washing with water several times, 100 g / l of active agent (trade name: NCL astoru, manufactured by Okuno Pharmaceutical Co., Ltd.) was used at 50° C. at a current density of 5.0 A / dm 2 Wash for 2 minutes under certain conditions, and perform electrolytic degreasing. Then, after washing with water several times, it was treated with 5% sulfuric acid at ...

Embodiment 2

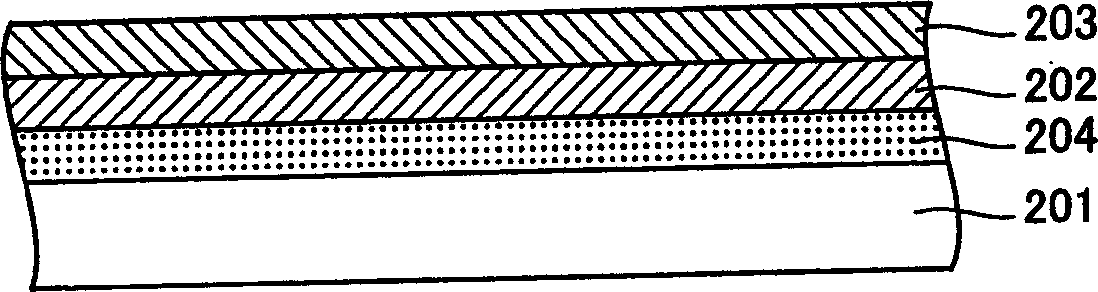

[0058] This embodiment is a connector terminal in which a base layer, a ruthenium layer, and a gold layer as a surface metal layer are sequentially formed on a conductive substrate. Refer to the following figure 2 Describe it.

[0059] First, as the conductive substrate 201 , strip-shaped phosphor bronze having a thickness of 0.1 mm was press-worked into the shape of a connector, and the continuous connector terminal shape was cut into a length of 70 mm. After cutting, it was washed with 50 g / l of an active agent (trade name: ACE CLEAN 30, manufactured by Okuno Pharmaceutical Co., Ltd.) at 53° C. for 3 minutes to perform a degreasing treatment. Then, after washing with water several times, 100 g / l of active agent (trade name: NCL astoru, manufactured by Okuno Pharmaceutical Co., Ltd.) was used at 50° C. at a current density of 5 A / dm 2 Wash for 2 minutes under certain conditions, and perform electrolytic degreasing. Then, after washing with water several times, it was trea...

Embodiment 3

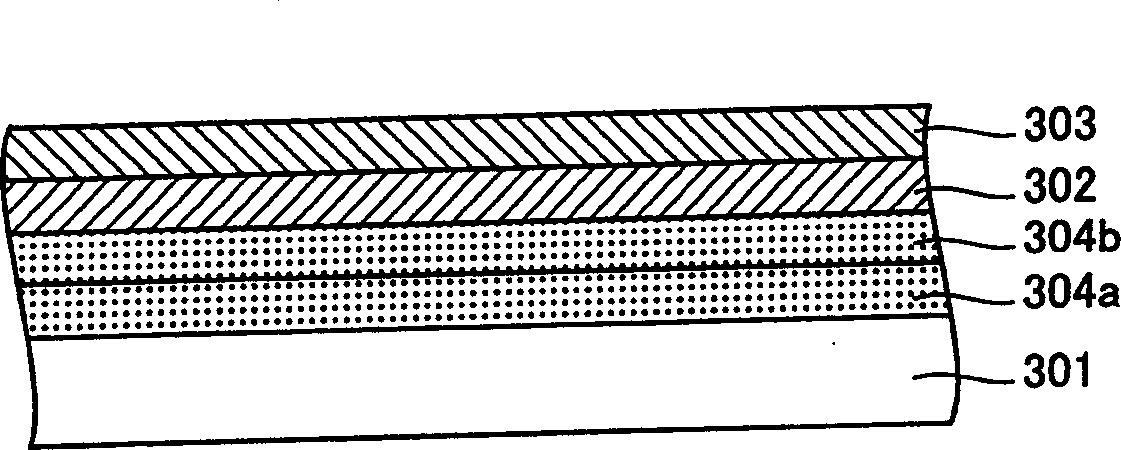

[0066] This embodiment is a connector terminal in which a plurality of underlayers, a ruthenium layer, and a gold layer as a surface metal layer are sequentially formed on a conductive substrate. Refer to the following image 3 Describe it.

[0067] First, as the conductive substrate 301 , a strip-shaped brass with a thickness of 0.1 mm was press-worked into the shape of a connector, and the continuous connector terminal shape was cut into a length of 70 mm. After cutting, it was washed with 50 g / l of an active agent (trade name: ACE CLEAN 30, manufactured by Okuno Pharmaceutical Co., Ltd.) at 53° C. for 3 minutes to perform a degreasing treatment. Then, after washing with water several times, use 100 g / l of active agent (trade name: NC Lastoru, manufactured by Okuno Pharmaceutical Industry Co., Ltd.) at 50 ° C and a current density of 5 A / dm 2 Wash for 2 minutes under certain conditions, and perform electrolytic degreasing. Then, after washing with water several times, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com