Process for preparing carbon nano fiber knitting macro-particles containing high active nickel catalyst

A carbon nanofiber, nickel catalyst technology, applied in the field of catalysis, can solve the problems of macroscopic carbon particles that do not meet industrial requirements, particle strength damage, low catalyst activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take Ni 2+ 、Cu 2+ 、Al 3+ Mix about 300ml of nitrate solution, the molar ratio is: Ni: Cu: Al = 75: 2: 23, the total concentration of metal ions is 1M; the temperature is raised to 55°C in a constant temperature water bath, and the concentration of 1M Na 2 CO 3 The solution is about 220ml; after fully reacting, filter the above reaction solution; wash the filtered precipitate with 65°C deionized water for 5 times; dry the washed precipitate at 120°C for 5 hours; grind the dried precipitate and sieve Obtain particles with a size of 10 mesh; calcinate the above particles at 450°C for 10h to obtain Ni-Cu / Al with a molar ratio of Ni:Cu:Al=75:2:23 2 o 3 Catalyst: Take 100mg of the above-mentioned catalyst particles and place them in a horizontal tubular reactor with an inner diameter of 38mm. The catalyst is first reduced with hydrogen at 750°C for 4h, and then cooled down to 500°C under the protection of nitrogen, and the volume ratio of feeding is 2:1 The mixed gas of ...

Embodiment 2

[0023] Take Ni 2+ 、Cu 2+ 、Al 3+ Mix about 300ml of nitrate solution, the molar ratio is: Ni:Cu:Al=75:15:10, the total concentration of metal ions is 1M; the temperature is raised to 60°C in a constant temperature water bath, and the concentration of 1M Na 2 CO 3 The solution is about 170ml; after fully reacting, filter the above reaction solution; wash the filtered precipitate with 60°C deionized water for 3 times; dry the washed precipitate at 120°C for 5 hours; grind the dried precipitate and sieve Obtain particles with a size of 20-40 mesh; calcinate the above particles at 450°C for 10h to obtain Ni-Cu / Al with a molar ratio of Ni:Cu:Al=75:15:10 2 o 3 Catalyst: Take 100mg of the above-mentioned catalyst particles and place them in a horizontal tubular reactor with an inner diameter of 38mm. The catalyst is first reduced with hydrogen at 700°C for 2h, then cooled down to 600°C under the protection of nitrogen, and then pure methane is introduced to react. It was 68ml / min...

Embodiment 3

[0025] Take Ni 2+ 、Cu 2+ 、Al 3+ Mix about 300ml of nitrate solution, the molar ratio is: Ni:Cu:Al=75:30:45, the total concentration of metal ions is 0.5M; the temperature is raised to 65°C in a constant temperature water bath, and the concentration of 1M Na 2 CO 3 The solution is about 260ml; after fully reacting, filter the above reaction solution; wash the filtered precipitate with 55°C deionized water for 7 times; dry the washed precipitate at 120°C for 5 hours; grind the dried precipitate and sieve Obtain particles with a size of 10-20 mesh; calcinate the above particles at 450°C for 10h to obtain Ni-Cu / Al with a molar ratio of Ni:Cu:Al=75:30:45 2 o 3 Catalyst: Take 250 mg of the above-mentioned catalyst particles and place them in a horizontal tubular reactor with an inner diameter of 38 mm. The catalyst is first reduced with hydrogen at 750 ° C for 4 hours, then cooled to 700 ° C under the protection of nitrogen, and then pure methane gas is introduced to react. The...

PUM

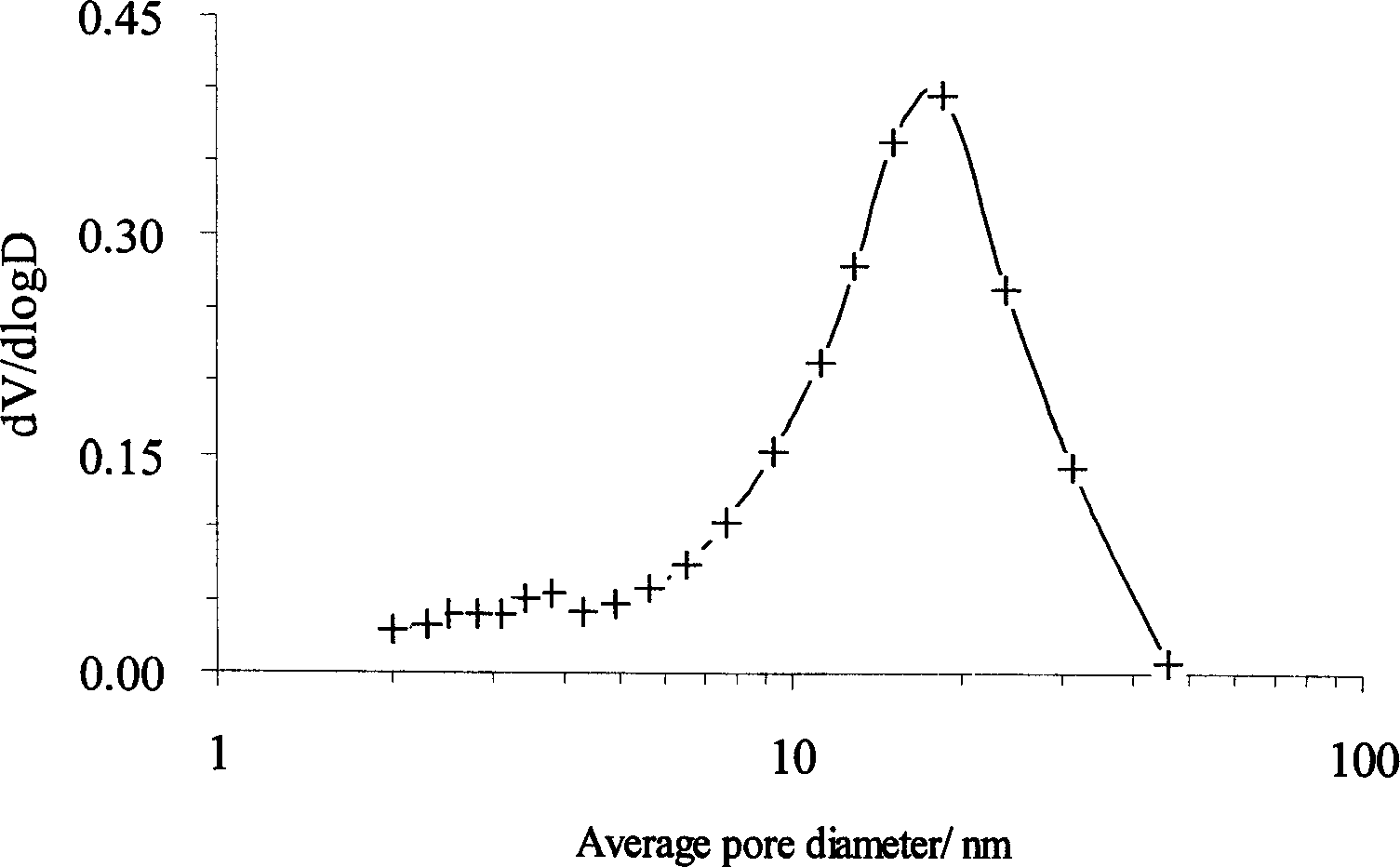

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com