Nano-ferroferric oxide/polystyrene magnetic composite material and its preparation method

A magnetic composite material, the technology of ferroferric oxide, applied in the direction of electrical components, etc., can solve the problems of microwave absorption, limited application range, and inability to shield electromagnetic waves, etc., and achieve the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

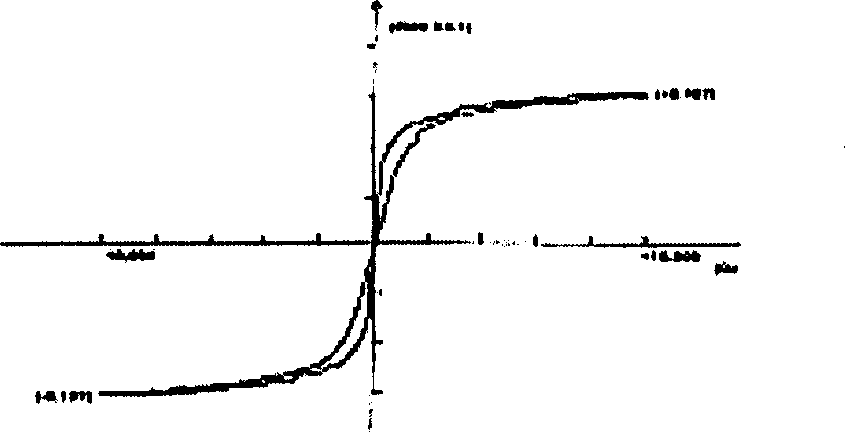

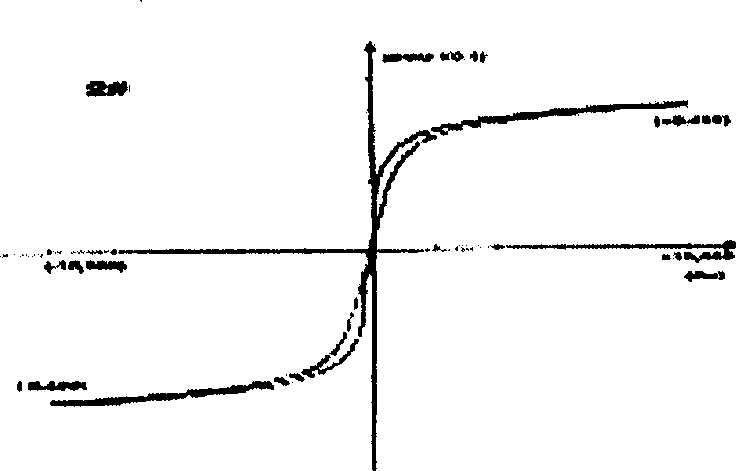

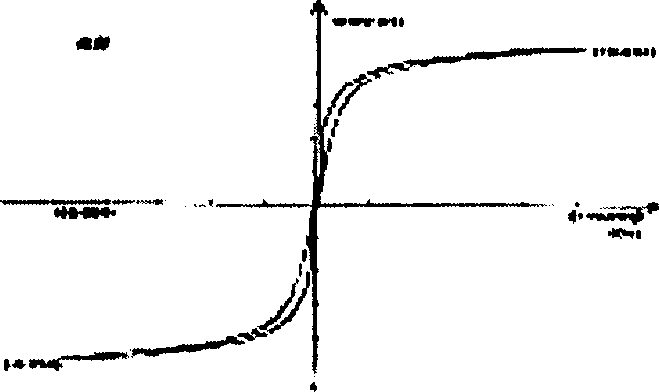

Image

Examples

Embodiment 1

[0023] Use ferric chloride, ferrous chloride and ammonia water to prepare 1mol / L, 2mol / L and 0.9mol / L aqueous solutions respectively; 3+ : Fe 2+ =2:1 (molar ratio) mix the ferric chloride solution and the ferrous chloride solution, stir at a high speed under the condition of 55°C, add 0.9mol / L ammonia water in two times, add four Oleic acid with 20% ferric oxide by weight, finally controlling the pH value of the solution at 10, collecting nano ferric oxide particles from the solution, with a particle size of about 10nm;

[0024] Then, the black nanometer iron ferric oxide particles obtained by the reaction were washed with deionized water to neutrality, and then washed with absolute ethanol for several times, and the washed iron ferric oxide particles were put into a vacuum oven at 70° C. for drying.

[0025] Put the dried nanometer ferric oxide and styrene monomer into a ball mill and carry out ball milling under the action of oleic acid for 36 hours to obtain a nanometer fe...

Embodiment 2

[0027] Use ferric chloride, ferrous chloride, and sodium hydroxide to prepare 1mol / L, 2mol / L, and 0.9mol / L aqueous solutions respectively; 3+ : Fe 2+ =2:1 (molar ratio) mix ferric chloride solution and ferrous chloride solution, stir at high speed under the condition of 60°C, add 0.9mol / L sodium hydroxide solution in two times, when the solution turns reddish brown When adding oleic acid with 20% weight of ferric oxide, the final pH value of the solution is controlled at 12 to obtain nanometer ferric oxide particles with a particle diameter of about 10nm. Then, the black nanometer iron ferric oxide particles obtained by the reaction were washed with deionized water to neutrality, and then washed with absolute ethanol for several times, and the washed iron ferric oxide particles were put into a vacuum oven at 70° C. for drying.

[0028] Put the dried nano ferric oxide and styrene monomer into the ball mill and carry out ball milling under the effect of surfactant oleic acid fo...

Embodiment 3

[0030] Use ferric chloride, ferrous chloride and ammonia water to prepare 1mol / L, 2mol / L and 0.9mol / L aqueous solutions respectively; 3+ : Fe 2+ =2:1 (molar ratio) mix the ferric chloride solution and the ferrous chloride solution, stir at a high speed under the condition of 50°C, add 0.9mol / L ammonia water in two times, add four Oleic acid with 20% by weight of ferric iron oxide was used to finally control the pH value of the solution at 8 to obtain ferric ferric oxide nanoparticles with a size of 10nm. Then, the black nanometer iron ferric oxide particles obtained by the reaction were washed with deionized water to neutrality, and then washed with absolute ethanol for several times, and the washed iron ferric oxide particles were put into a vacuum oven at 70° C. for drying.

[0031] Put the dried nano ferric oxide and styrene monomer into the ball mill and carry out ball milling under the effect of surfactant oleic acid for 36 hours to obtain the nano ferric oxide / styrene d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com