Production process of nano rod-like active silica with attapulgite and clay

A technology of attapulgite clay and activated silica, applied in the direction of silica, fibrous fillers, etc., to achieve the effects of reduced raw material consumption, reduced production costs, and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

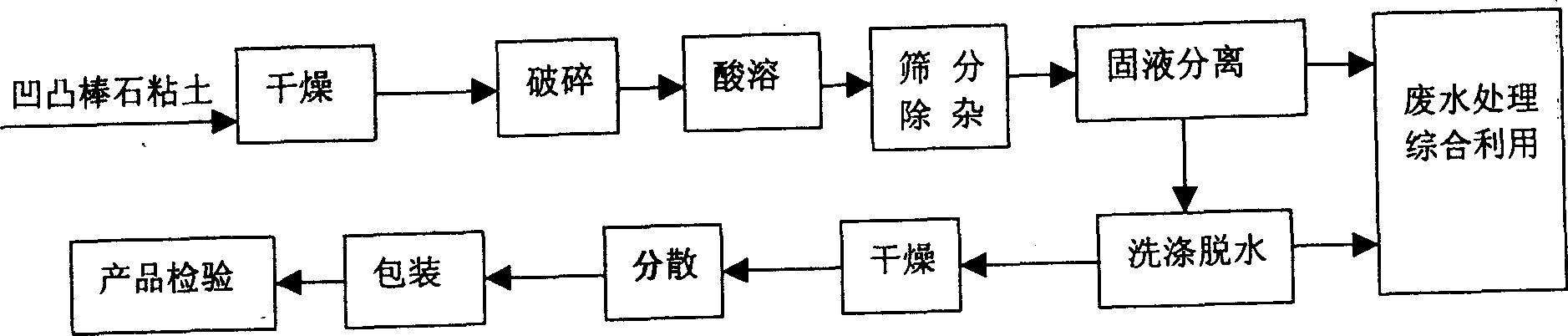

Method used

Image

Examples

Embodiment Construction

[0010] In this example, attapulgite clay is used as raw material to produce nano-rod-shaped active silica by one-step direct acid dissolution method.

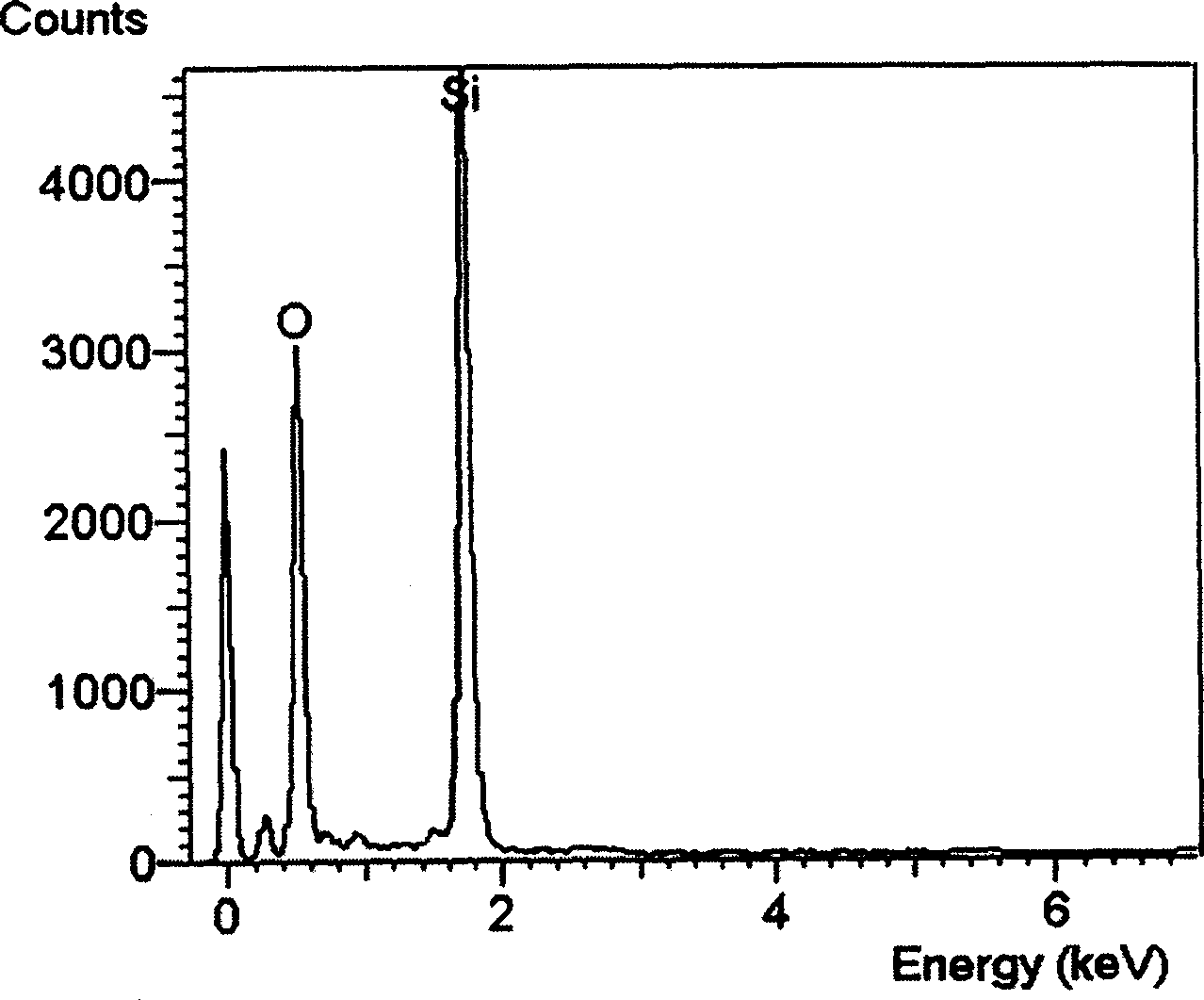

[0011] figure 1 and figure 2 The morphology and composition of nanorod-shaped active silica are shown, respectively. The basic principle is that the octahedral cations Mg, Al, and Fe in the attapulgite structure can be completely dissolved under the action of strong acid, while the SiO as the silica backbone of attapulgite 2 The crystal morphology of attapulgite is preserved, resulting in the production of nanorod-shaped activated silica (silica).

[0012] The specific implementation of this embodiment is preferably that the attapulgite content in the attapulgite clay is not less than 60%, and minerals such as quartz and feldspar are not more than 5%. The less the content of quartz and feldspar is, the better, and the less content of dolomite can reduce the acid consumption of chemical reactions.

[0013] The acid used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com