Preparation method of glass fibre thin felt

A technology of glass fiber and thin felt, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of bound glass fiber thin felt application field, difficult to meet people's new requirements, low uniformity, etc., and achieve good bonding performance , low water absorption and adequate supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

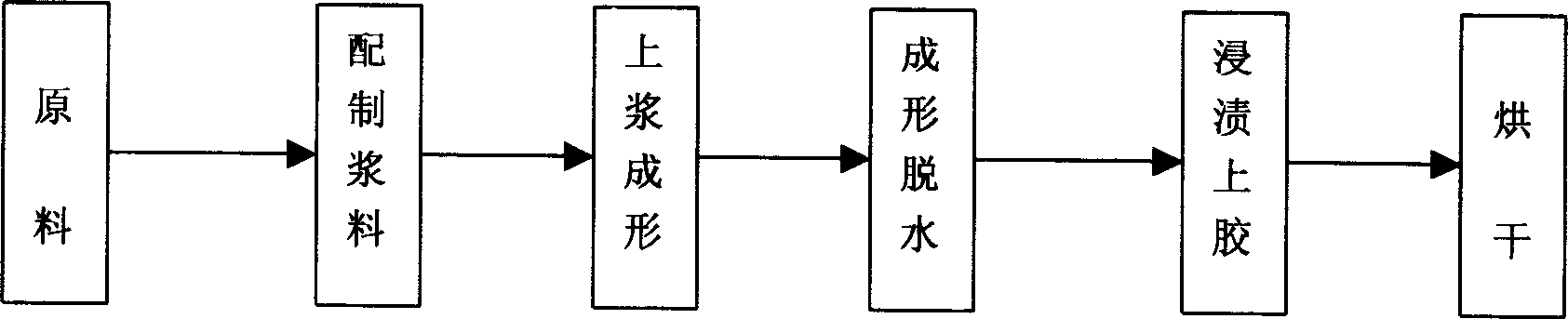

Method used

Image

Examples

Embodiment 1

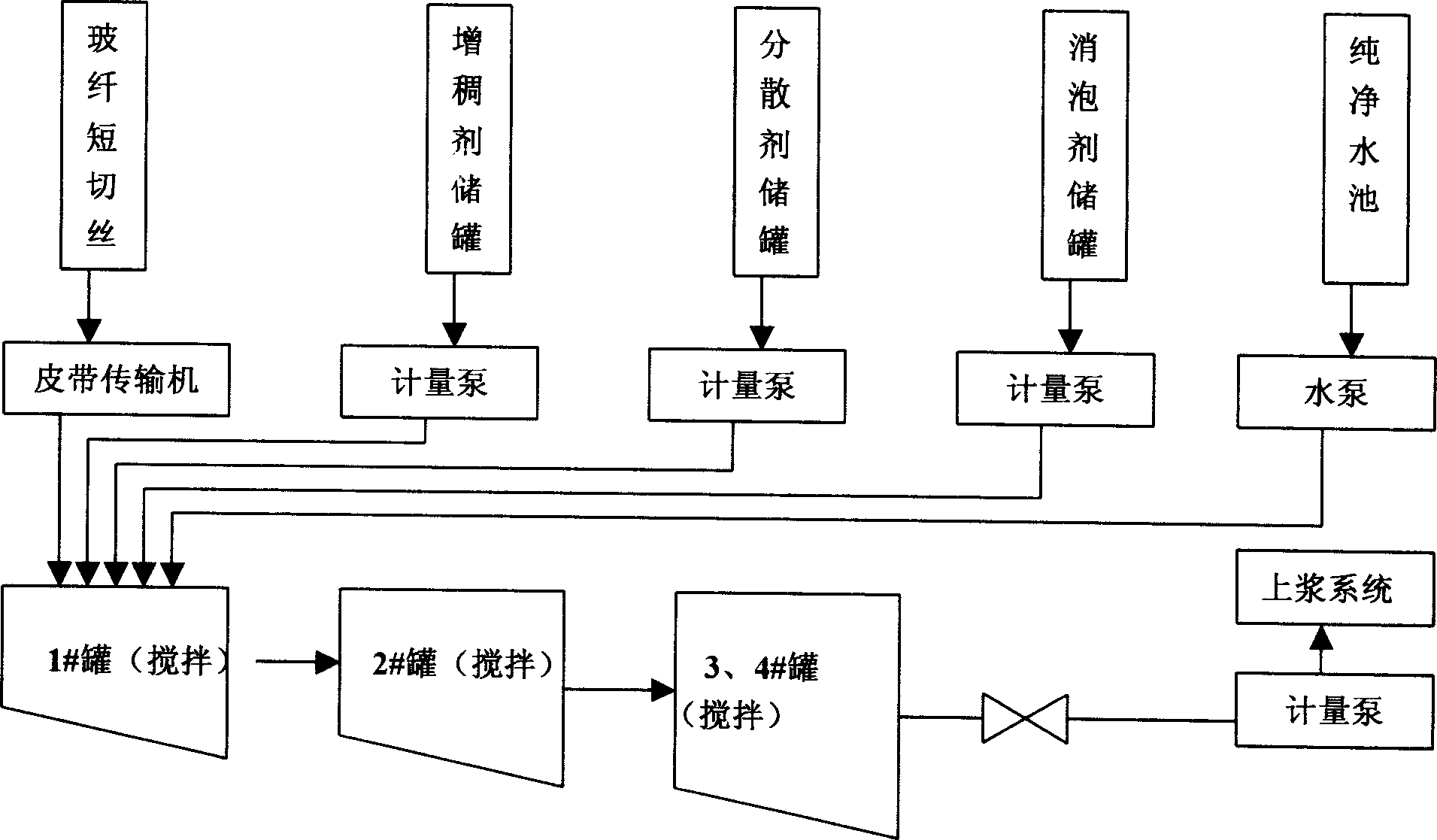

[0033] Prepare slurry:

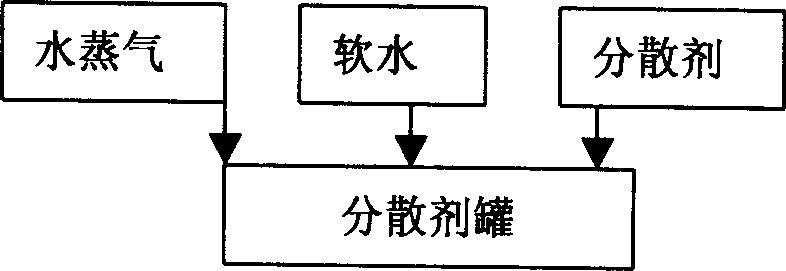

[0034] Add glass fiber chopped strands and white water into a stirring tank and stir evenly. The concentration of glass chopped strands is 0.1%. The glass fiber chopped strands have a diameter of 9 μm and a length of 6 mm. The white water contains thickeners, dispersants, Foaming agent, add thickener, dispersant and defoamer in pure water, make the viscosity of white water reach 8CP; The concentration of dispersant in white water is 80ppm; The gas content in white water is controlled at 6%; Described thickener is Hydroxyethyl cellulose is an easy-to-buy product in the market. Its appearance is: white powder or white sandy particles, viscosity 4000-6000mpas, moisture ≤ 5%; ash content ≤ 10%; light transmittance ≥ 95%;

[0035] Described dispersing agent is polycondensate of fatty acid, is the direct dispersing agent of man-made chopped fiber of non-woven product, also is the easy-to-buy commodity in market, and its appearance is: white, the liquid that ...

Embodiment 2

[0047] Prepare slurry:

[0048] Add glass fiber chopped strands and white water into a stirring tank and stir evenly. The concentration of glass chopped strands is 0.2%. The glass fiber chopped strands have a diameter of 10 μm and a length of 10 mm. Foaming agent, the add-on of thickener makes the viscosity of white water reach 10CP; The concentration of dispersant in white water is 90ppm; The add-on of defoamer makes the air content in white water be controlled at 8%; Described organic binder is The mixed solution of acrylic emulsion and coupling agent (KH560), their content in thin felt is 12%.

[0049] The thickener is hydroxyethyl cellulose; the dispersant is fatty acid polycondensate, which is the direct dispersant of artificial chopped fibers of non-woven products; the defoamer is Agitan295;

[0050] Sizing forming, forming dehydration, dipping, gluing, drying and coiling are the same as in Example 1, except that the binding agent is made up of acrylic acid emulsion and...

Embodiment 3

[0053] Prepare slurry:

[0054] Add glass fiber chopped strands and white water into a stirring tank and stir evenly. The concentration of glass chopped strands is 0.3%. The glass fiber chopped strands have a diameter of 10 μm and a length of 13 mm. Foaming agent, the add-on of thickener makes the viscosity of white water reach 9CP; The concentration of dispersant in white water is 100ppm; The add-on of defoamer makes the air content in white water be controlled at 8%; Described organic binder is Mixture of thermosetting acrylate and coupling agent (KH560), their content in thin felt is 20%.

[0055] The thickener is hydroxyethyl cellulose; the dispersant is fatty acid polycondensate; the defoamer is Agitan295;

[0056] Sizing forming, forming dehydration, dipping and sizing and drying coiling are the same as in Example 1, except that the binder is made up of thermosetting acrylate and coupling agent (KH560), and its weight percentage is: polyvinyl acetate emulsion 80%, coupli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com