Label for shaping in mould and container for shaping in mould having the label

An in-mold forming and labeling technology, applied in the direction of marking non-rigid containers, labeling, instruments, etc., can solve the problems of low productivity, easy fire caused by organic solvents, inhomogeneous, bright and stable printing, etc., to achieve efficient manufacturing and reduce coating. Cloth process and manufacturing equipment limitations, effect of good in-mold label applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0114] Hereinafter, the present invention will be described more specifically by taking preparation examples, production examples, working examples, comparative examples, and test examples as examples. The materials, usage amounts, ratios, processing contents, processing order, etc. shown in the following examples can be appropriately changed without departing from the scope of the present invention. Therefore, the scope of the present invention is not limited to the explanation of the specific examples described below.

[0115] (Preparation Example 1) Preparation of Surface Treatment Agent (D)

[0116] In a reactor equipped with a loop cooler, a thermometer, a dropping funnel, a stirrer and a gas introduction pipe, 500 parts by weight of diallylamine hydrochloride (aqueous solution with a concentration of 60% by weight), 13 parts by weight of diallylamine hydrochloride parts of acrylamide (aqueous solution with a concentration of 40% by weight) and 40 parts by weight of wate...

manufacture example

[0121] Base material films (Production Examples 1 to 8) satisfying the conditions of the present invention and base films used in Comparative Examples (Production Examples 9 to 15) were produced in the following procedure.

[0122] The materials used are detailed in Table 1. "MFR" in the table refers to melt flow rate. Table 2 describes the types and amounts of materials (wt %), stretching conditions, thickness of each layer, and opacity used in the manufacture of various substrate films. The material numbers described in Table 2 correspond to the material numbers described in Table 1. In addition, the addition amount of the dispersing agent in Table 2 is represented by the weight part with respect to 100 weight part of total addition amounts of materials 1-3.

[0123] In Production Examples 1 to 6, 9, and 10, the compound [A] described in Table 2 was melt-kneaded in an extruder set at 250°C, and after extrusion molding, it was cooled to 70°C in a cooling device, A single l...

Embodiment 1~8、 comparative example 1~7

[0136] The dispersion composed of the heat-sealable resin described in Table 3, the anti-blocking agent described in Table 3, and water were mixed so that a predetermined solid content concentration could be obtained to prepare the water-based coating agent described in Table 4. The water-based coating agent was applied on the surface side of the substrate films of Production Examples 1 to 15 at a line speed of 20 m / min with a slot-die coater, and dried in an oven with a set length of 10 m at the drying temperature described in Table 4. A heat-sealable resin coating layer was formed to obtain a film for an in-mold label. Table 4 shows the coating amount of the obtained film after drying.

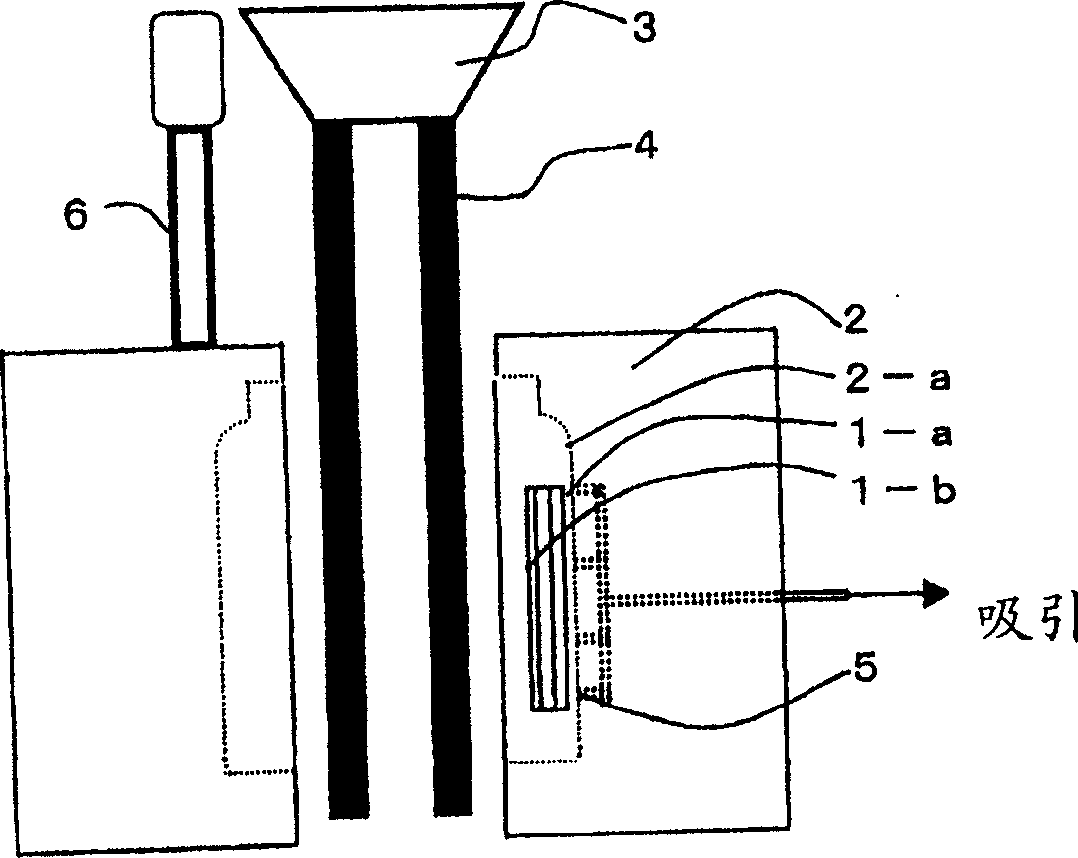

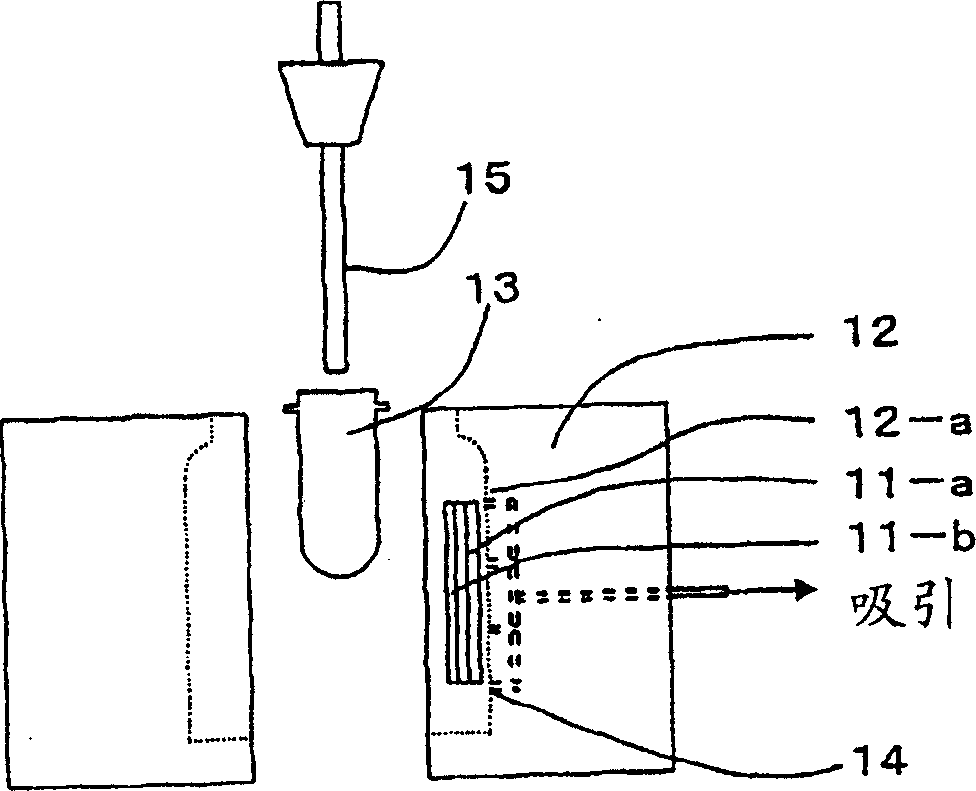

[0137] Inkjet printing and gravure printing were performed on the surface provided with the heat-sealable resin coating layer of the obtained film under the following conditions, and after the inner surface decoration pattern was prepared, it was punched out with a length of 70 mm and a widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com