Technology for industrialized production of hydrochloric acid multi-donepezil

A technology of donepezil hydrochloride and a process method, which is applied in the process field of industrialized production of donepezil hydrochloride, can solve the problems of high product impurities, low product yield, and high raw material cost, and achieve the effects of simplified operation procedures, reasonable process design, and improved product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

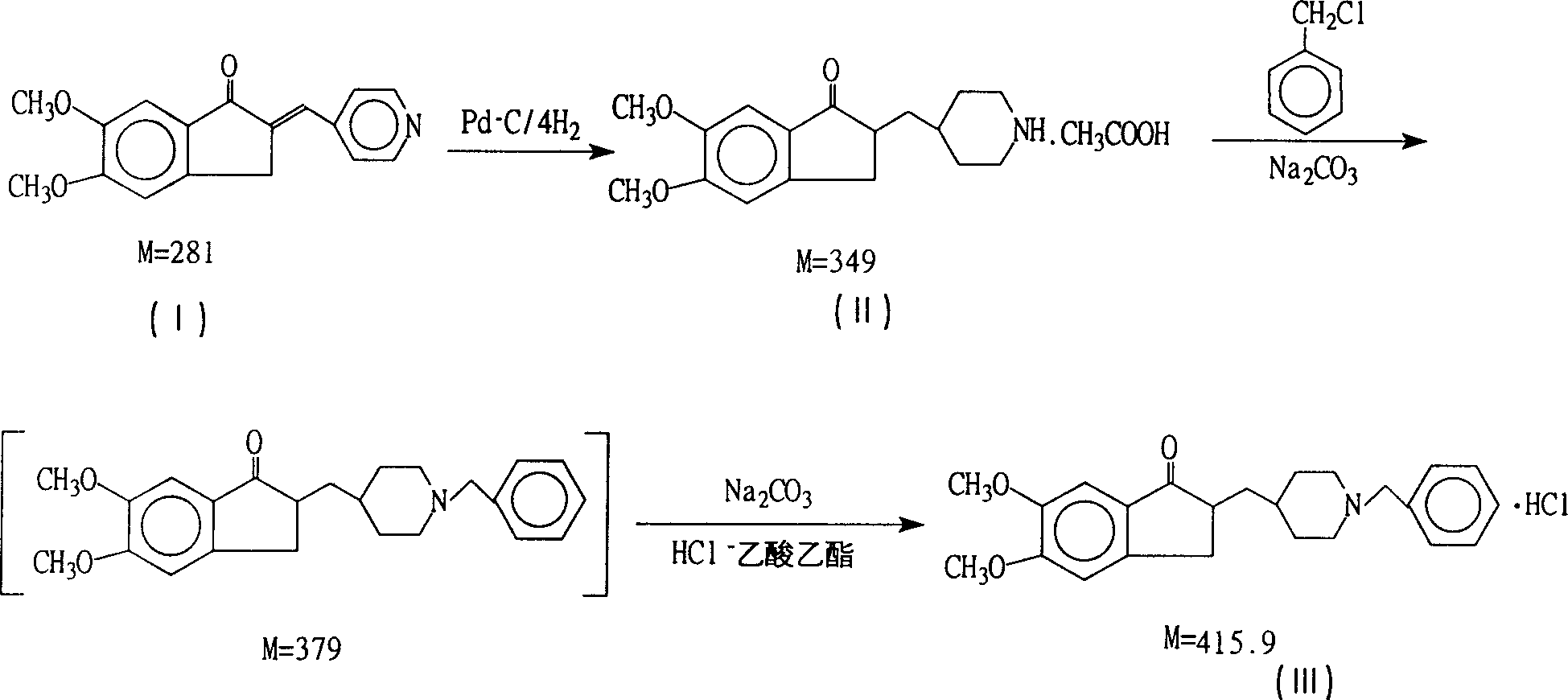

[0025] 1. Preparation of 5,6-dimethoxy-2-(4-piperidinylmethyl)-indan-1-one acetate

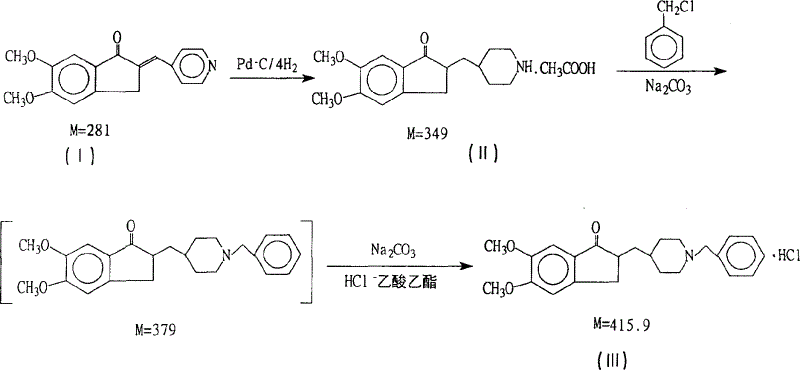

[0026] (1) Reaction formula:

[0027]

[0028] (2) Feeding amount and mole number:

[0029] (I) 3.0g (0.011Mol)

[0030] Palladium / carbon 0.3g(W / W10%)

[0031] Absolute ethanol 60ml (V / W 20 times)

[0032] Acetic acid 0.7ml (0.012Mol)

[0033] (3) Operation:

[0034] Use a 100 ml autoclave, put in the above raw materials, ventilate three times, 80-100 ° C, 2.0 MPa pressure, stir the reaction, hydrogen absorption reaches the theoretical amount, filter out palladium / carbon, and the HPLC content is ≥ 97%.

[0035] (4) Recovery of solvents and treatment of three wastes:

[0036] Palladium / carbon continues to be used and can be applied several times.

[0037] The ethanol reaction solution was directly used in the next reaction.

[0038] The preparation method of raw material (I) refers to J.Heter.Chem.2(4)366,1965.

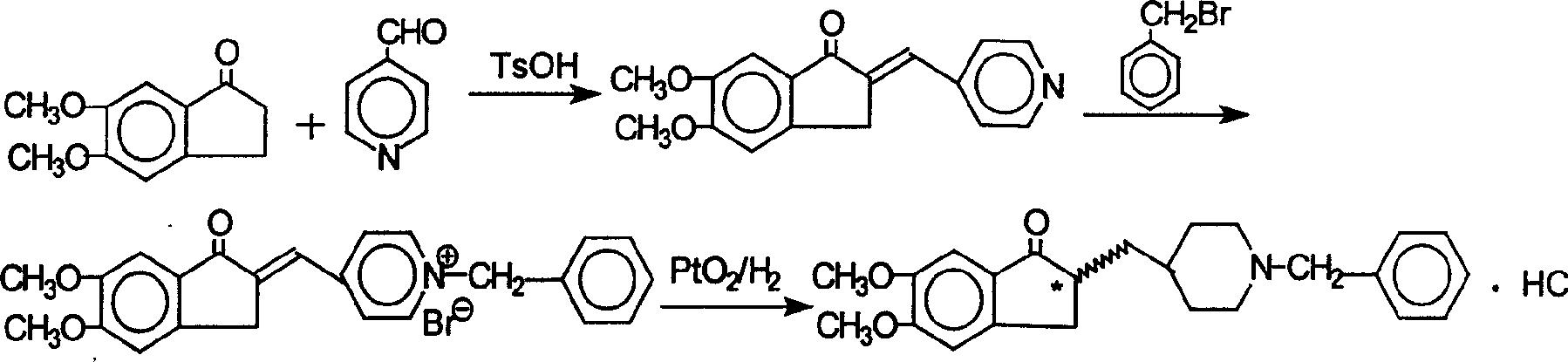

[0039] 2. Preparation of (±) 2,3 dihydro-5,6-dimethoxy-2-{[(1-benzyl)-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com