Composite bone tissue engineering rack material and its prepn

A technology of bone tissue engineering and scaffold materials, applied in medical science, prosthesis, etc., can solve the problems of damaged cells, insufficient strength of polymer materials, and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

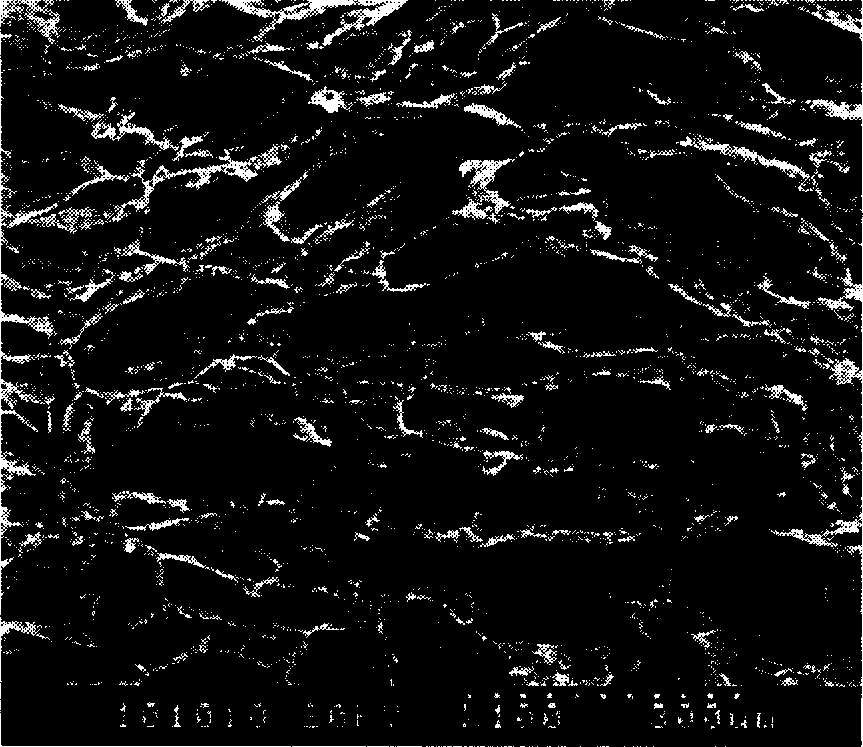

[0018] With 0.3% malonic acid solution as the swelling solution, a collagen swelling solution with a solid content of 0.5% was prepared. Weigh 60 g of collagen swelling solution with a solid content of 0.5% and 0.3 g of hydroxyapatite, and mix them uniformly to obtain a collagen-HA dispersion. Pre-freeze at -30°C for at least 4 hours, then freeze-dry at -30°C for 15 hours, -15°C for 18 hours, 0°C for 15 hours, 10°C for 7 hours, and 20°C for 4 hours to obtain uncrosslinked collagen-HA scaffold materials.

[0019] At room temperature, soak the prepared uncrosslinked collagen-HA scaffold material in 40% ethanol containing 120ml50mmol / L2-morpholineethanesulfonic acid (MES) for 30min, then soak the collagen-HA scaffold material in 120ml crosslinked Solution (containing 50mmol / L MES, 24mmol / L carbodiimide (EDC), 5mmol / L succinimide (NHS), 0.2% chondroitin sulfate) cross-linked at room temperature for 4h. Put the scaffold in 0.1mol / L Na 2 HPO 4 Wash in water for 1 hour, wash in 1m...

Embodiment 2

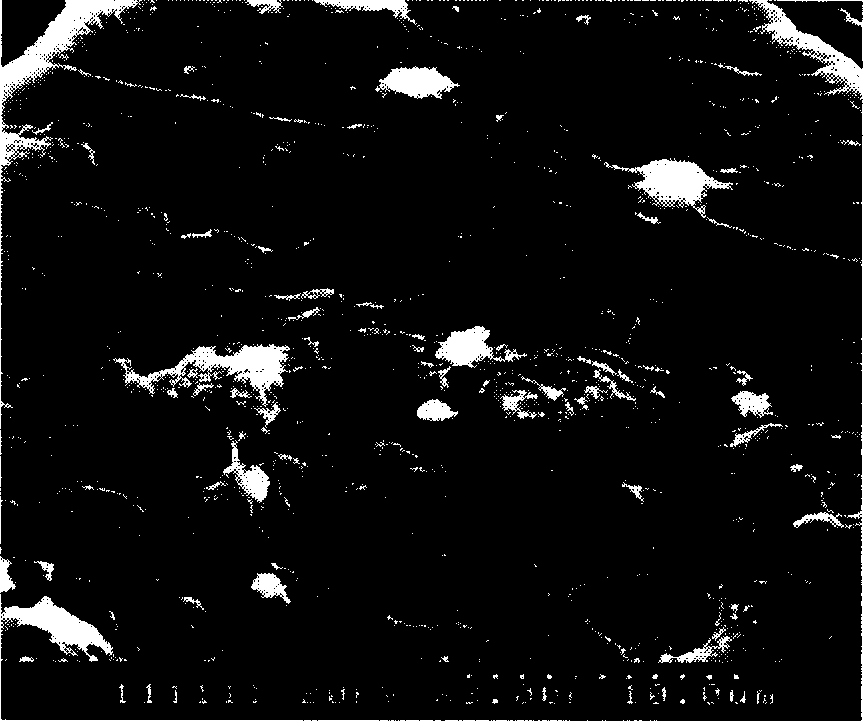

[0029]With 0.3% malonic acid solution as the swelling solution, a collagen swelling solution with a solid content of 0.5% was prepared. Weigh 60 grams of collagen swelling solution with a solid content of 0.5% and 1.2 grams of hydroxyapatite, and mix them uniformly to obtain a collagen-HA dispersion. Pre-freeze first, and then freeze-dry to obtain uncrosslinked collagen-HA scaffold material.

[0030] At room temperature, soak the prepared uncrosslinked collagen-HA scaffold material in 40% ethanol containing 120ml50mmol / L2-morpholineethanesulfonic acid (MES) for 30min, then soak the collagen-HA scaffold material in 120ml crosslinked Solution (containing 50mmol / L MES, 24mmol / L carbodiimide (EDC), 5mmol / L succinimide (NHS), 0.5% chondroitin sulfate) cross-linked at room temperature for 4h. Put the scaffold in 0.1mol / L Na 2 HPO 4 Wash for 1 hour in 1 mol / L NaCl, 2 hours in 1 mol / L NaCl, 1 day and night in 2 mol / L NaCl, and finally, wash with water to remove residual cross-linki...

Embodiment 3

[0033] With 0.3% malonic acid solution as the swelling solution, a collagen swelling solution with a solid content of 0.7% was prepared. Weigh 60 grams of collagen swelling solution with a solid content of 0.7% and 0.84 grams of hydroxyapatite, and mix them uniformly to obtain a collagen-HA dispersion. Pre-freeze first, and then freeze-dry to obtain uncrosslinked collagen-HA scaffold material.

[0034] At room temperature, soak the prepared uncrosslinked collagen-HA scaffold material in 40% ethanol containing 168ml50mmol / L2-morpholineethanesulfonic acid (MES) for 30min, then soak the collagen-HA scaffold material in 168ml crosslinked Solution (containing 50mmol / L MES, 24mmol / L carbodiimide (EDC), 5mmol / L succinimide (NHS), 0.2% chondroitin sulfate) cross-linked at room temperature for 4h. Put the scaffold in 0.1mol / L Na 2 HPO 4 Wash for 1 hour in 1 mol / L NaCl, 2 hours in 1 mol / L NaCl, 1 day and night in 2 mol / L NaCl, and finally, wash with water to remove residual cross-lin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com