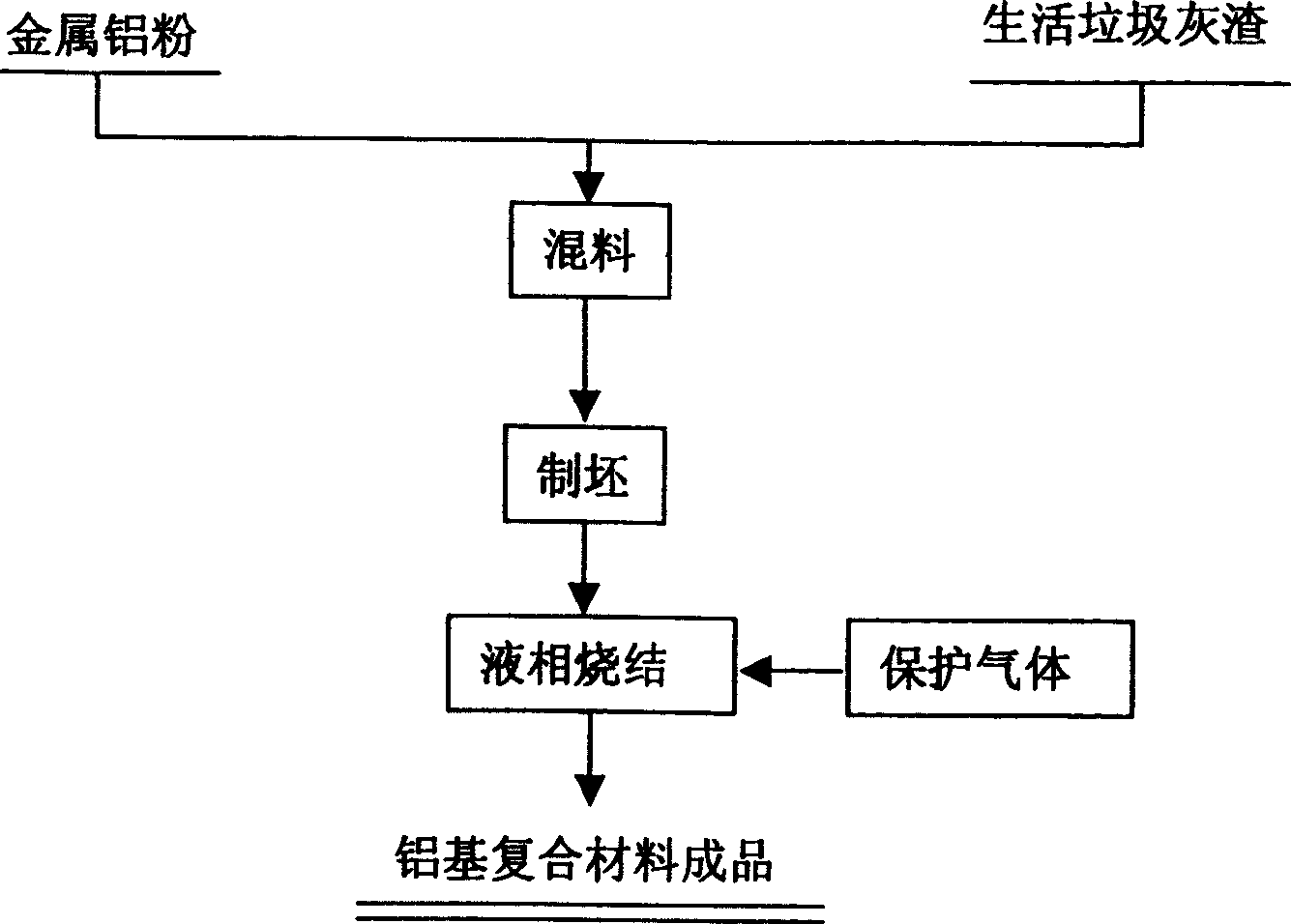

Method of preparing aluminium-base composite material with aluminium and domestic garbage cinder

A technology of aluminum-based composite materials and domestic waste, which is applied in the field of aluminum-based composite materials prepared from aluminum and domestic waste ash, can solve the problems of easy oxidation and creep, high brittleness of ceramic particles, strong heat resistance, and strong corrosion resistance. Effect of improving strength and elastic modulus, good toughness and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

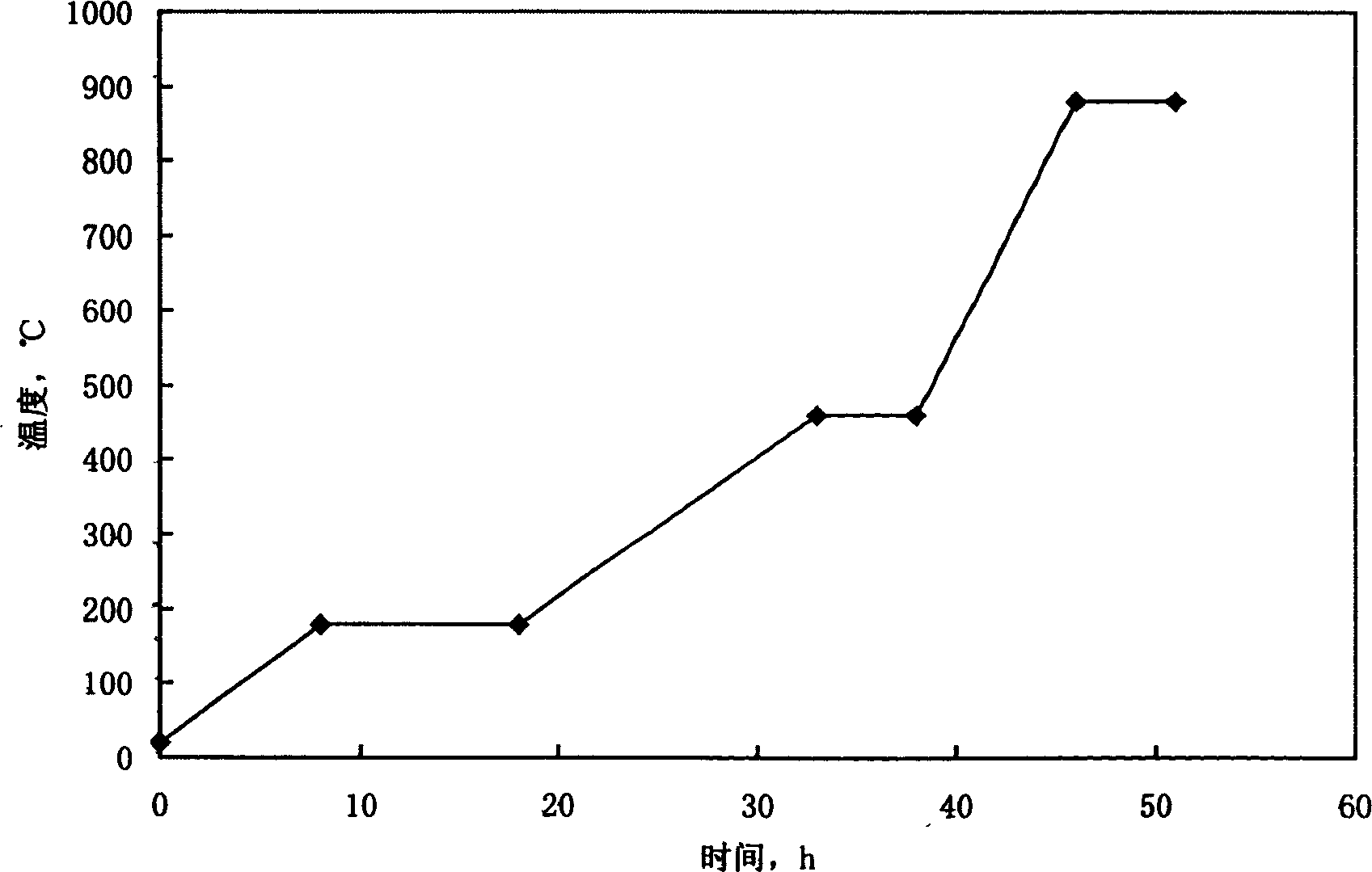

[0021] 1) Implementation conditions

[0022] The mass ratio of the aluminum metal powder material to the domestic waste ash with a particle size below 74 μm is 83:17. After mixing evenly, press it into a compact with a diameter of 10×15 mm in a press under a pressure of 6.8 MPa. Liquid-phase sintering in a sintering kiln fed with a nitrogen protective gas atmosphere, according to figure 2 The liquid phase sintering system is carried out in the liquid phase sintering system. The sintering system is as follows: firstly, the temperature is raised to 180 ° C at a heating rate of 20 ° C / h, and the temperature is maintained for 10 h; With a heating rate of 52.5°C / h, the temperature was raised to a final temperature of 880°C, kept for 5 hours, and the finished product was obtained by liquid phase sintering.

[0023] 2) Implementation results

[0024] The finished product has good mechanical properties. The coefficient of thermal expansion is 0.3 and the density is 2.43g / cm 3 ,...

Embodiment 2

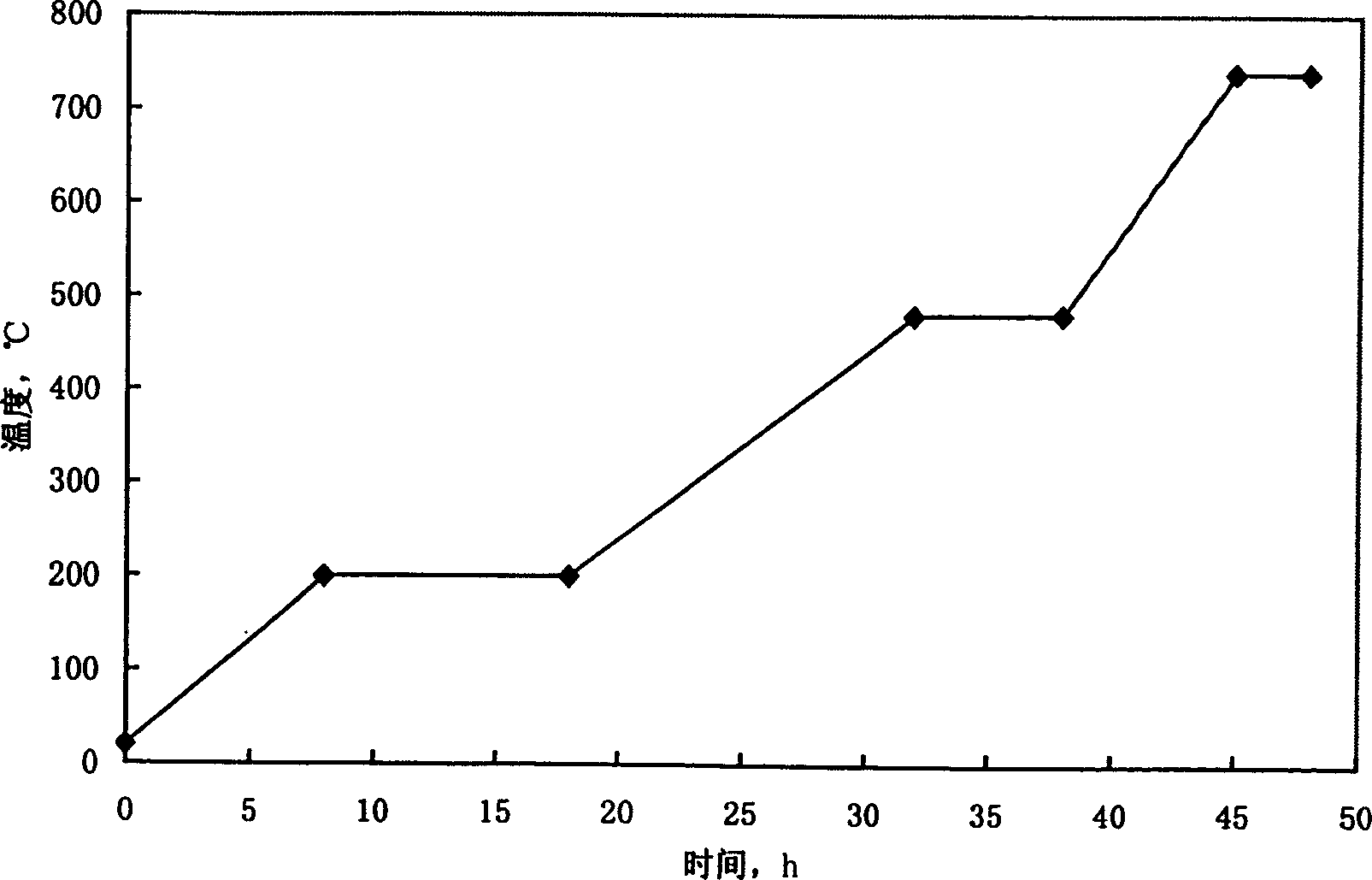

[0026] 1) Implementation conditions

[0027] The mass ratio of the aluminum metal powder material to the domestic waste ash with a particle size below 74 μm is 91:9. After mixing evenly, press it into a compact with a diameter of 10×15 mm in a press under a pressure of 5.8 MPa. Liquid-phase sintering in a sintering kiln fed with a nitrogen protective gas atmosphere, according to image 3 The liquid phase sintering system is carried out in the liquid phase sintering system. The sintering system is as follows: firstly, the temperature is raised to 200 ° C at a heating rate of 22.5 ° C / h, and the temperature is maintained for 10 hours; then the temperature is increased to 480 ° C at a heating rate of 20 ° C / h, and the temperature is maintained for 6 hours; With a heating rate of 37.1°C / h, the temperature was raised to a final temperature of 740°C, held for 3 hours, and the finished product was obtained by liquid phase sintering.

[0028] 2) Implementation results

[0029] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com