Method for treating waste water of chinese yam saporin and recovering gluocose and hydrochloric acid by membrane integrating technique

A diosgenin and technical treatment technology, applied in the field of wastewater treatment technology, can solve problems such as difficulty in reaching the first-level discharge standard, ineffective utilization of glucose and hydrochloric acid, etc., and achieve no secondary pollution, convenient operation, and running costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

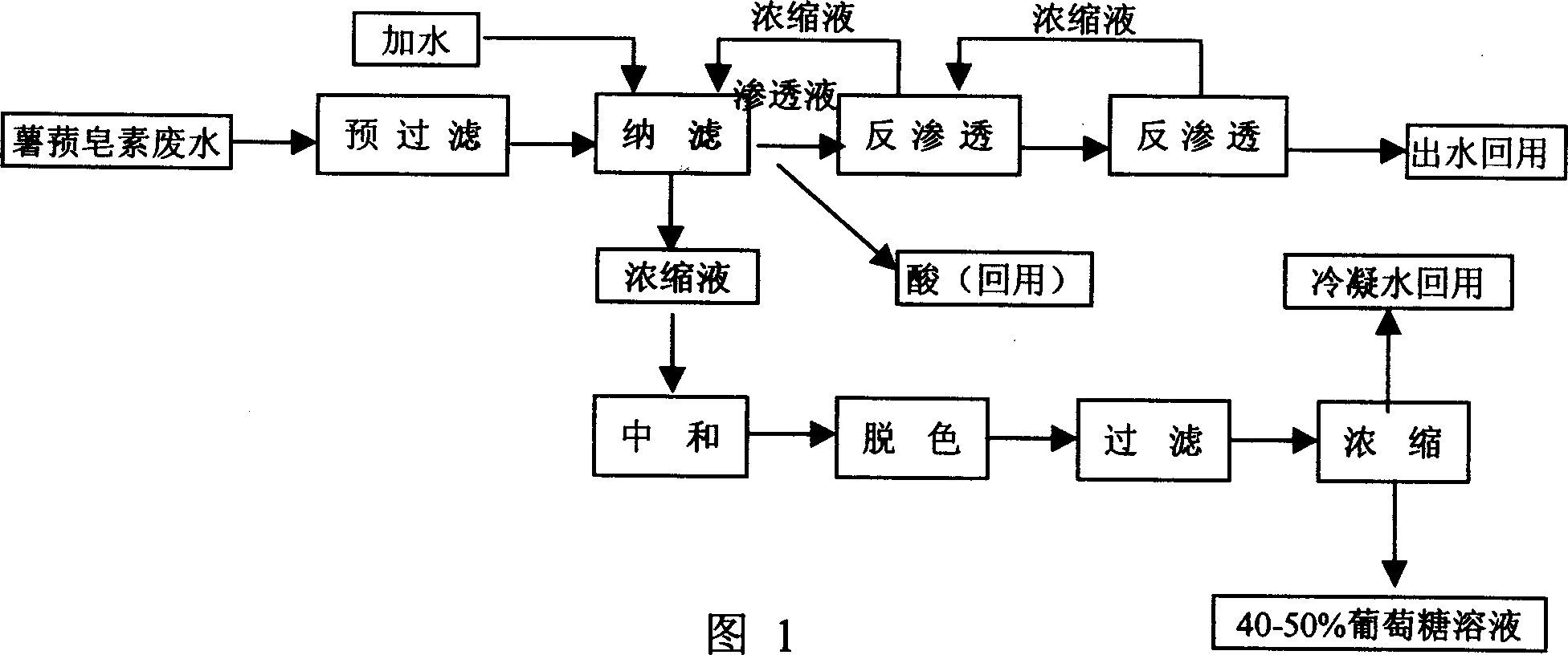

[0035] As shown in Figure 1, the method for membrane integration technology to process dioscin waste water and reclaim glucose and hydrochloric acid is realized by the following steps: 1), pretreatment: 100L of dioscin waste water (hydrolyzate), COD105000mg / L, pH value 0.16 , temperature 36°C; filtered through an alumina microfiltration membrane with a pore size of 200nm, the filtration pressure is 0.41MPa, and the average flux is 197L / m 2 h, remove suspended solids or macromolecular impurities to obtain 93L of filtrate. 2), recovery of glucose and hydrochloric acid: deacidification with nanofiltration membrane, the average flux under the pressure of 1.8MPa is 6.5L / m 2 h, hydrochloric acid aqueous solution permeates the membrane to obtain hydrochloric acid, while the intercepted is glucose concentrate. 3) Advanced treatment: adding 40L of water to the concentrated nanofiltration solution to deacidify it, and the first-level advanced treatment after the permeate is neutralized...

Embodiment 2

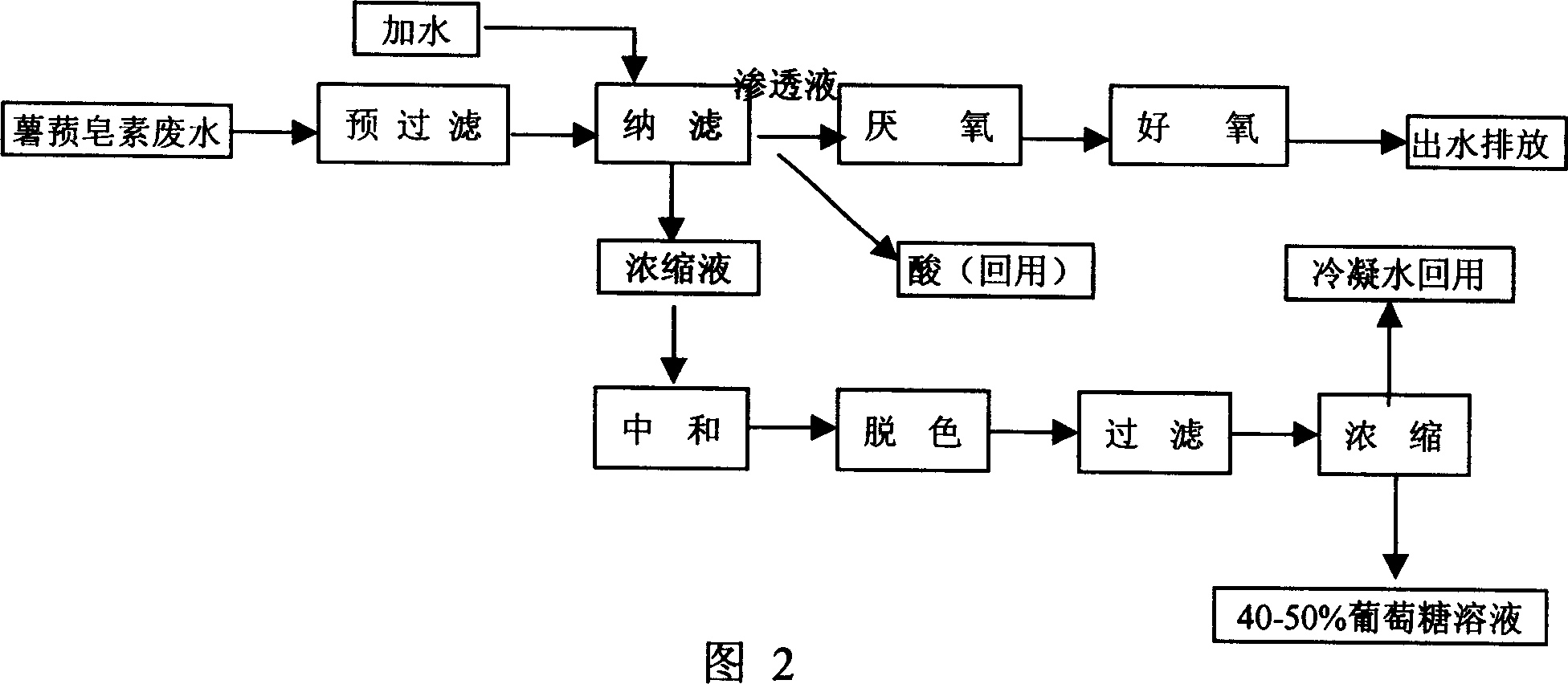

[0038] The method for treating diosgenin wastewater by membrane integration technology and recovering glucose and hydrochloric acid is realized by the following steps: 1), pretreatment: 100L of diosgenin wastewater (hydrolyzate), COD96000mg / L, pH value 0.18, temperature 32°C; 100nm zirconia microfiltration membrane filtration, the filtration pressure is 0.41MPa, the average flux is 247L / m2h, and the suspended solids or macromolecular impurities are removed to obtain the filtrate. 2), recovery of glucose and hydrochloric acid: the filtrate is deacidified by nanofiltration membrane, the pressure is 1.8MPa, and the average flux is 6.0L / m 2 h; Hydrochloric acid aqueous solution permeates the membrane to obtain hydrochloric acid, and what is intercepted is glucose concentrate. 3) Advanced treatment: Add 80L of water to the concentrated solution to deacidify to obtain 35L of concentrated sugar solution. The first-level advanced treatment of the deacidified permeate is a nanofiltrati...

Embodiment 3

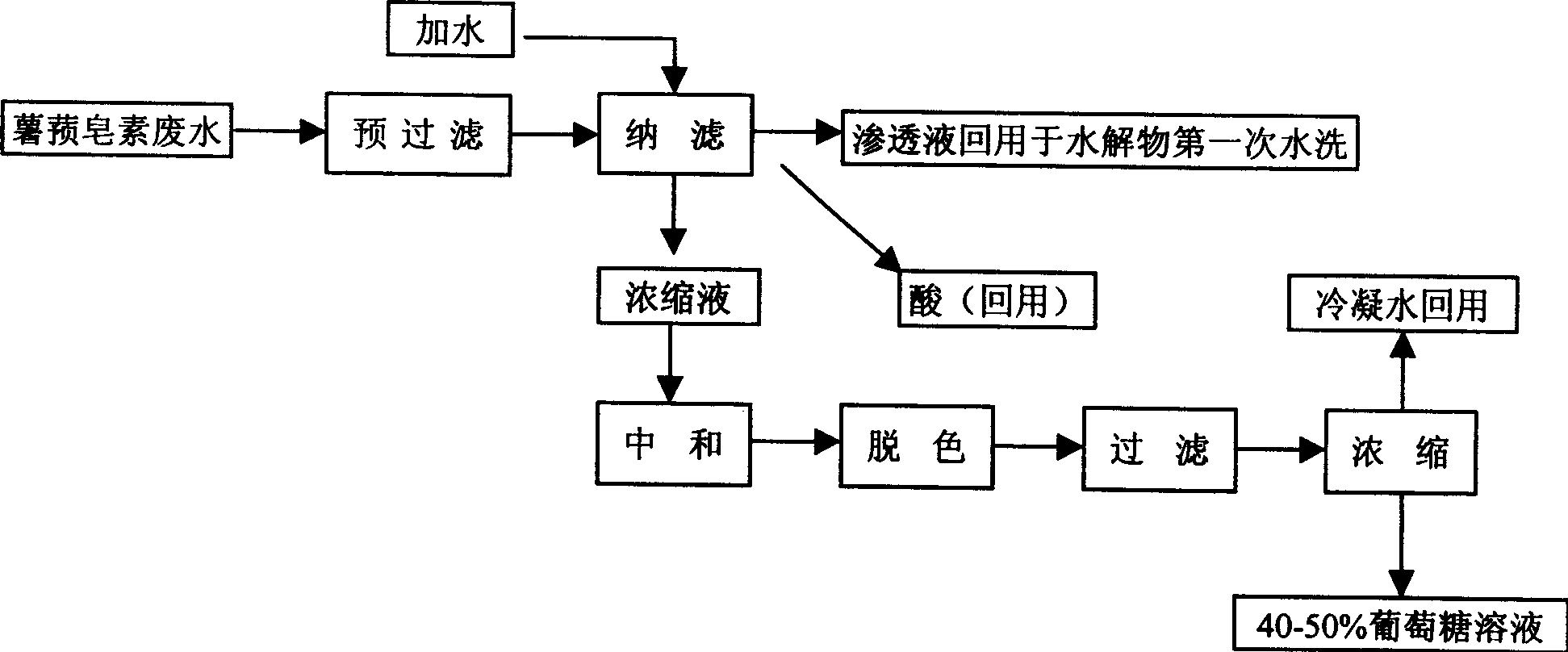

[0041] The method for treating diosgenin wastewater by membrane integration technology and recovering glucose and hydrochloric acid is realized by the following steps: 1), pretreatment: 100L of diosgenin wastewater (hydrolyzate), COD88000mg / L, pH value 0.21 temperature 34°C; Suction filtration to obtain the filtrate. 2), recovery of glucose and hydrochloric acid: the obtained filtrate is deacidified by nanofiltration membrane, and the average flux under the pressure of 1.8MPa is 11.8L / m 2 h; Hydrochloric acid aqueous solution permeates the membrane to obtain hydrochloric acid, and what is intercepted is glucose concentrate. 3) Advanced treatment: 36L of concentrated solution was obtained, 60L of water was added for further deacidification, the permeate was neutralized, and two-stage advanced treatment was carried out with a low-pressure reverse osmosis membrane, and the average flux under a pressure of 1.8MPa was 9.3L / m 2 h and 25.4L / m 2 h, effluent COD78mg / L.

[0042] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com