Non symmetrical porous polytetrafluoro membrane for clothing material

A polytetrafluoroethylene film, asymmetric technology, applied in the field of materials for clothing, can solve the problem of bonding strength, can not meet the water resistance, air permeability and water vapor transmission capacity, and reduce the bonding force and film performance. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

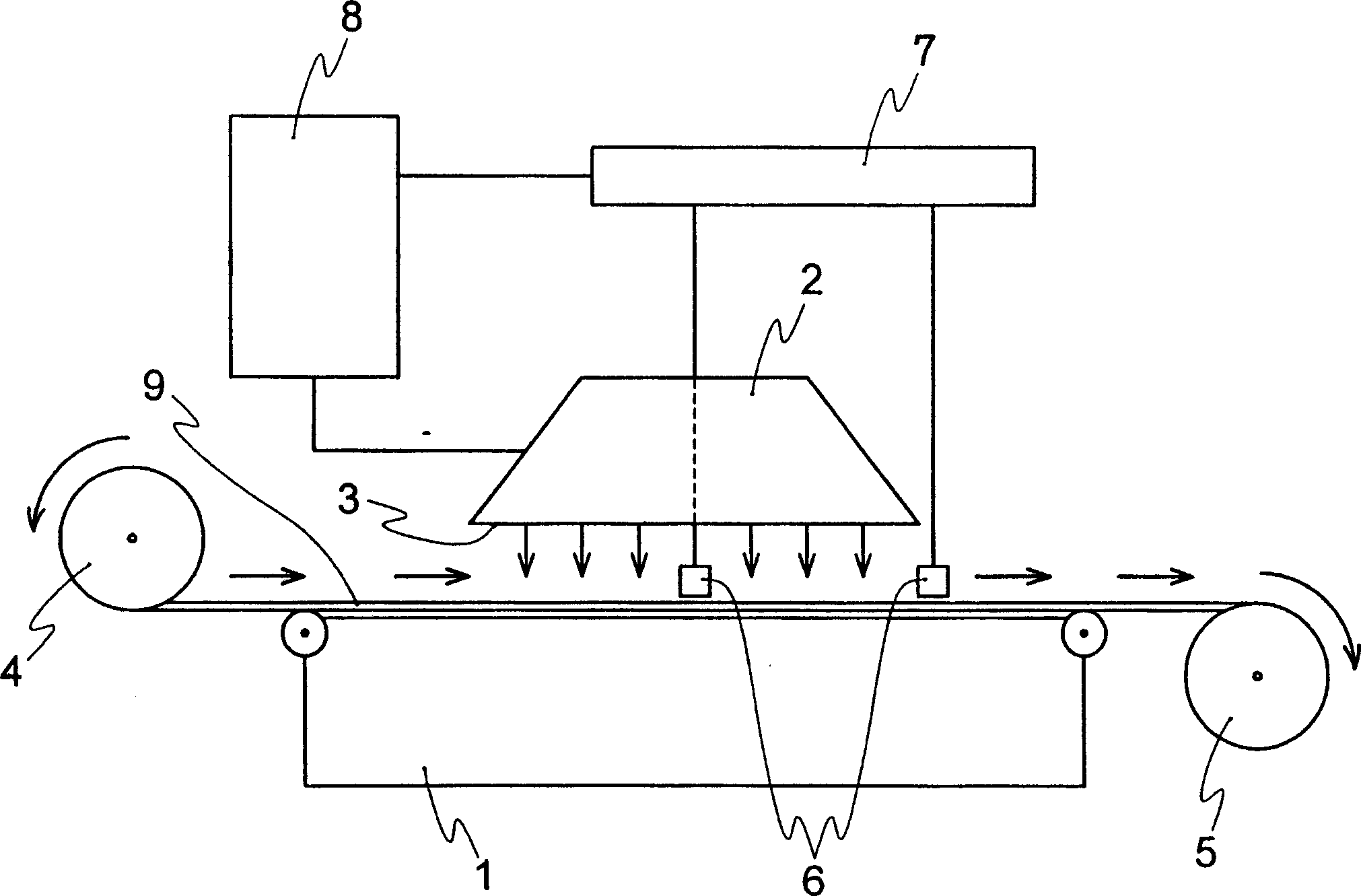

Method used

Image

Examples

Embodiment 1~3

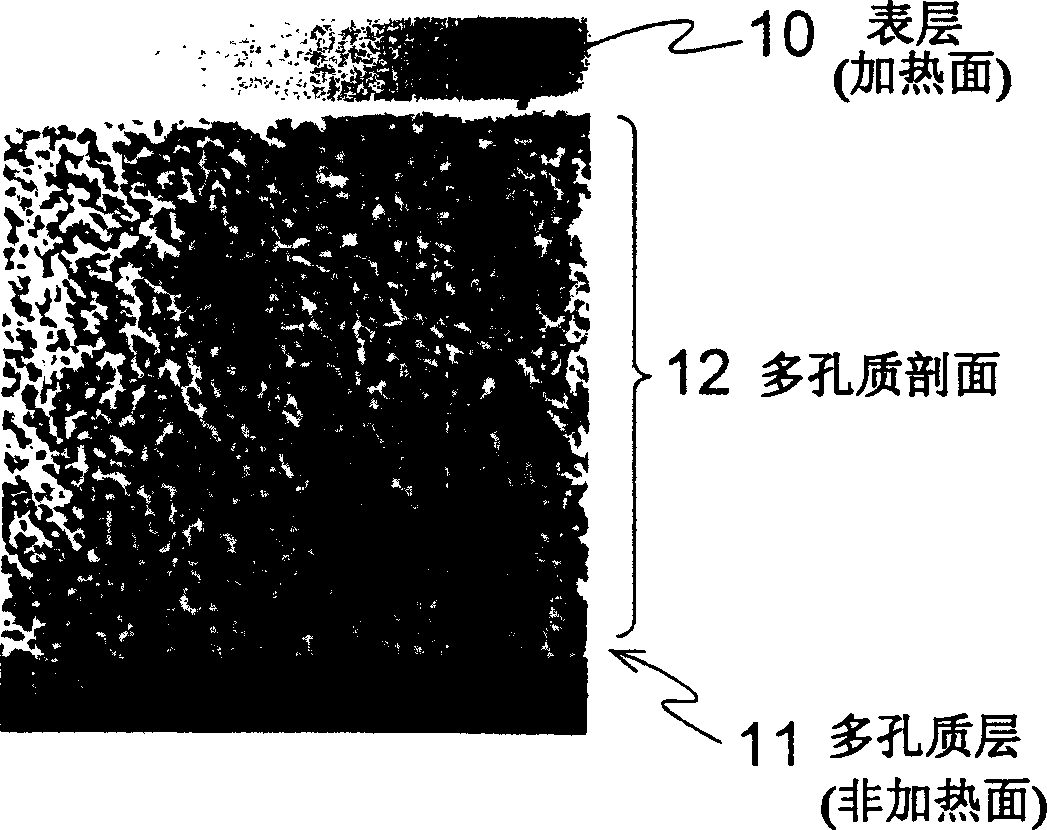

[0107] Extrude the pasty mixture of 80 parts by weight of PTFE fine powder and 20 parts by weight of naphtha produced by emulsion polymerization with an extruder at a reduction ratio of 80:1 to obtain a rod-shaped extrudate with a diameter of 18 mm. The rod-shaped extruded product was rolled in the same direction as the extrusion direction with a calender roll having a diameter of 500 mm, to obtain a plate-shaped rolled product having a width of 260 mm and a thickness of 0.2 mm. The naphtha was removed by heating the plate to 260°C in an oven. Next, after preheating the sheet to 300° C., simultaneous biaxial stretching was carried out at a stretch ratio of 500% in the rolling direction and at a ratio of 300% in a direction perpendicular thereto. While maintaining this stretched state, it was heated at 340° C. for 15 seconds to complete heat setting. Thereafter, it was cooled to room temperature, and the thickness of the prepared symmetrical porous PTFE membrane was 20-25 μm, ...

Embodiment 4~6

[0113] A polyester / cotton (50 / 50%) blended fabric having a thickness of about 0.1 mm was laminated on one side of the asymmetric porous PTFE membrane produced in Examples 1 to 3 to obtain a clothing material. The lamination process uses moisture-permeable hot-melt polyurethane as an adhesive, coats it on the surface of the asymmetric porous PTFE membrane, and then sticks the blended fabric on it, and then, through Finish by hardening the polyurethane adhesive. Table 2 shows the evaluation results of water vapor permeability and air permeability before and after dry cleaning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com