Composite powder of stannic oxide Nano crystal with silver being covered

A technology of tin oxide nanocrystals and composite powders, which is applied in tin oxide, liquid chemical plating, metal material coating technology, etc., can solve the problems of low comprehensive performance of materials, high material hardness, large contact resistance, etc., and achieve improved Processability and electrical performance, obvious economic benefits, and the effect of reducing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

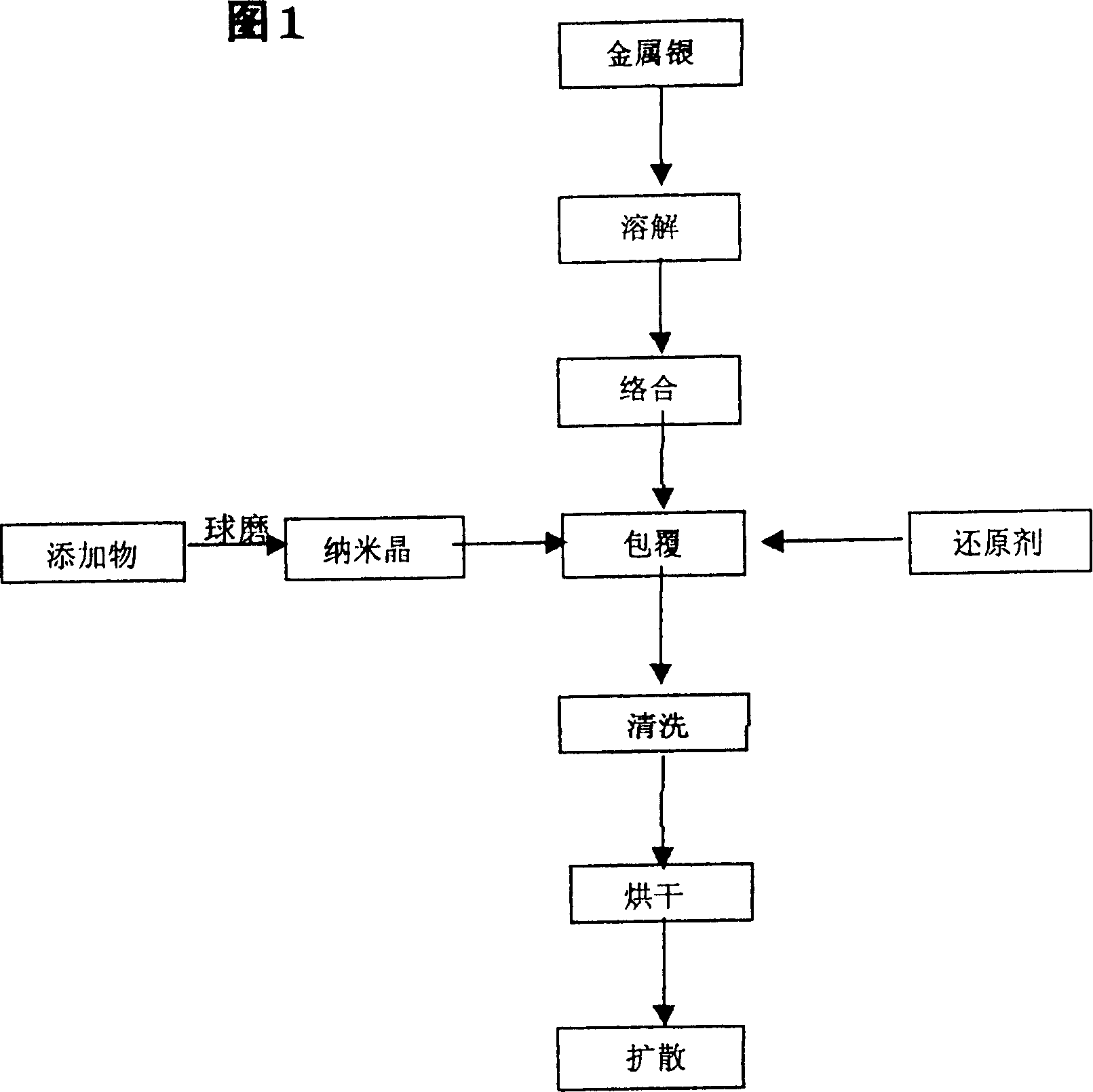

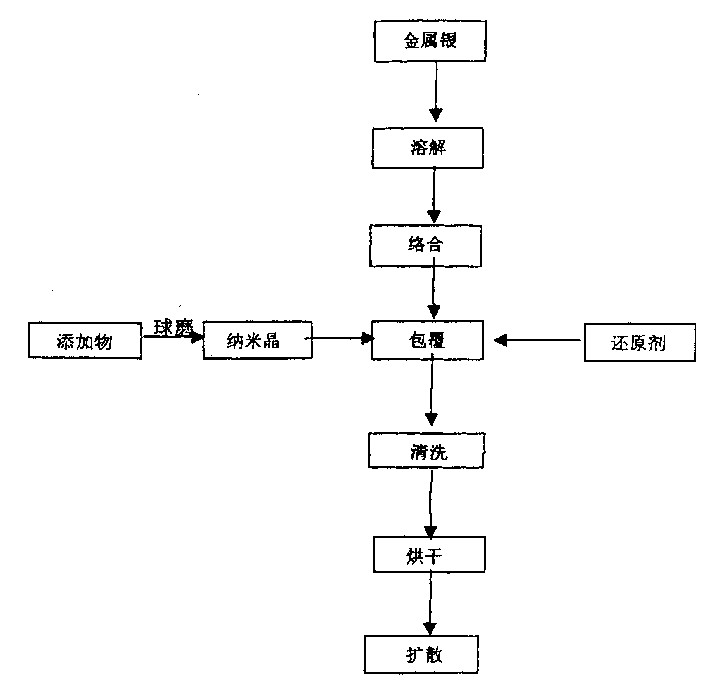

[0014] Referring to Figure 1, this is the flow chart of the method for preparing the additive powder nanocrystalline composite powder. It can be seen from the figure that the additive tin oxide powder is subjected to high-energy ball milling to obtain tin oxide nanocrystals; before coating the tin oxide powder, first Metal silver is dissolved in nitric acid to become a silver nitrate solution, and ammonia water is used for complexation treatment. While starting the mixer, the reducing agent hydrazine hydrate is dropped into the stirring solution through the capillary, and tin oxide powder is sprinkled into the container at the same time. Wash with deionized water until the pH of the discharged water is 7. The wet powder is dried in an oven at a temperature of 160°C. The dried powder is crushed and sieved, and then diffused at a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com