A electron beam chemical amplitude positive resist and method for making same and photoetching technology

A chemical amplification and positive resist technology, which is applied to the photolithography process of the pattern surface, the photolithography exposure device, and the microlithography exposure equipment, etc., which can solve the problems such as difficult start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

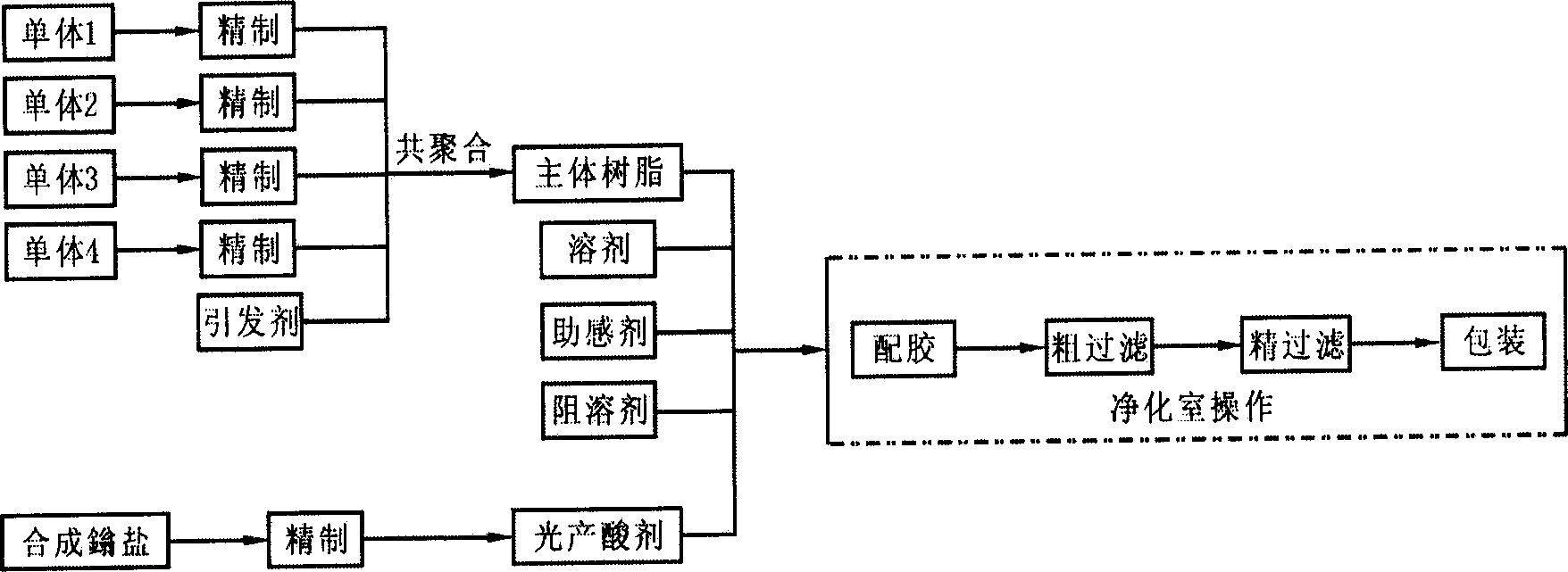

Image

Examples

Embodiment 1

[0047] Synthesis of host resin copolymer P(MMA-TBMA-MAA-IBMA)

[0048] In a 500ml four-necked flask, add purified MMA20g (0.2mol), MAA8.6g (0.1mol), TBMA21.3g (0.15mol), IBMA11.1g (0.05mol), then add THF150g, AIBN0.2g, pass Inject nitrogen, start stirring, control the reaction temperature to 65°C, and react for 24 hours. Pour the reactant into 1000ml cyclohexane for precipitation, suction filtration, take out the filter cake and dissolve it in 150ml THF, then precipitate it in 1000ml cyclohexane, suction filtration, repeat three times, then put the filter cake into a vacuum drying oven , baked at 60°C for 24 hours to obtain 38g of the main resin copolymer P(MMA-TBMA-MAA-IBMA).

Embodiment 2

[0050] Synthesis of host resin copolymer P(MMA-TBMA-MAA-IBMA)

[0051] The operation steps are the same as in Example 1, but the feeding amounts of MMA, MAA, TBMA, and IBMA are respectively 20g, 4.3g, 21.3g, and 22.2g to obtain 39.2g of the main resin copolymer P (MMA-TBMA-MAA-IBMA).

Embodiment 3

[0053] Compounding Technology of Electron Beam Chemically Amplified Positive Resist

[0054] Get the copolymer resin 13g of embodiment 1, add solvent ethylene glycol ethyl ether acetate 86g, photoacid generator diphenyl iodine trifluoromethanesulfonate 0.5g, synesthesia agent 2,4-dimethoxybenzoic acid 0.1 g and 0.5 g of tert-butyl cholate, a solvent-repelling solvent, were stirred and dissolved, and then filtered with a 0.1 μm filter membrane to obtain an electron beam chemically amplified positive resist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com