Plate permanetic linear synchronous machine for machine tool feeding system

A permanent magnet linear synchronization and feeding system technology, applied in the propulsion system, electromechanical device, shape/style/structure of winding conductors, etc. The effect of large thrust, improved thrust and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Flat permanent magnet linear synchronous motors can be used in the feed drive system of high-speed CNC machine tools and machining centers, and can also be used in the feed drive system of various special processing equipment (such as laser cutting, plasma cutting, EDM, etc.).

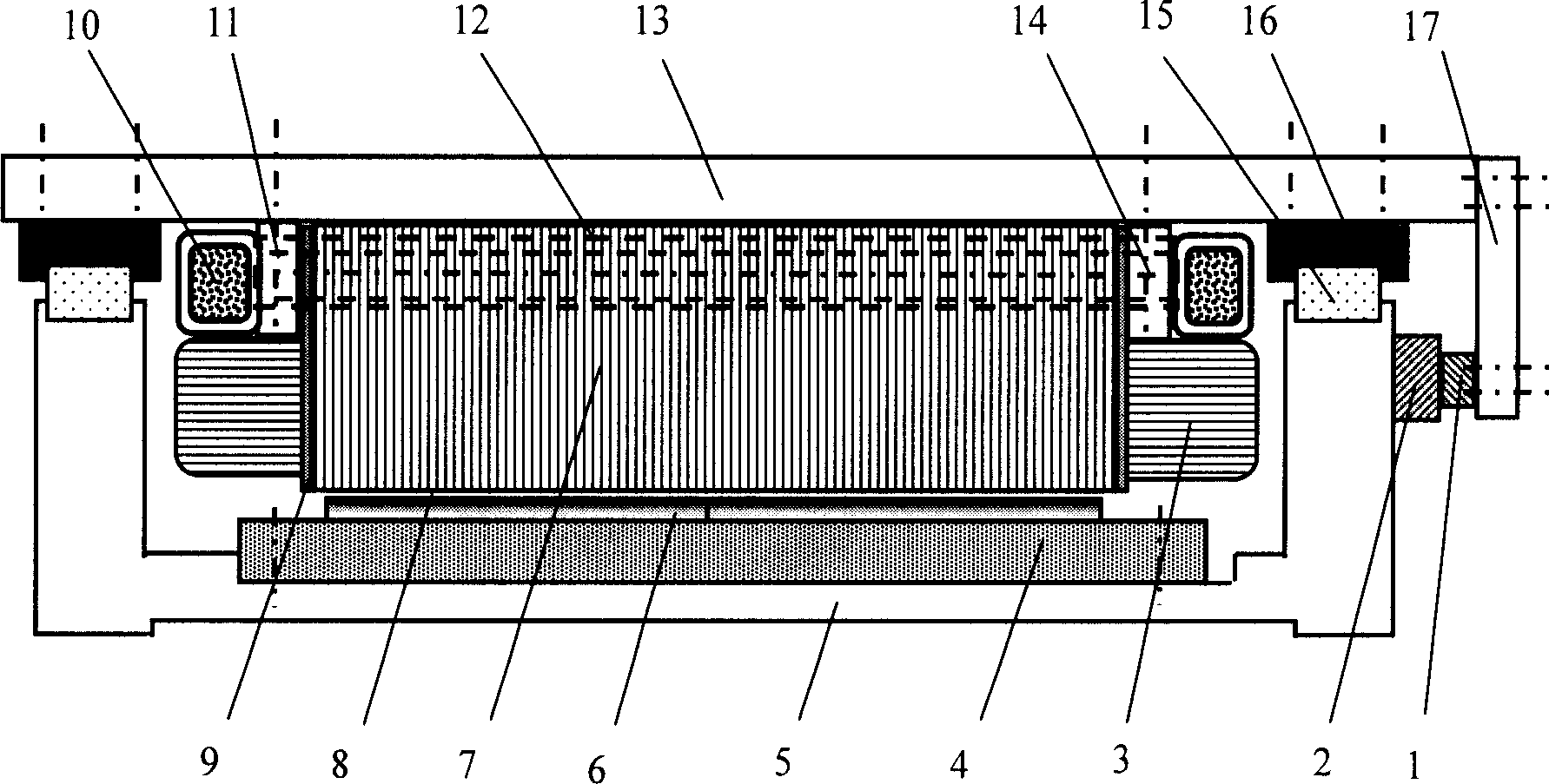

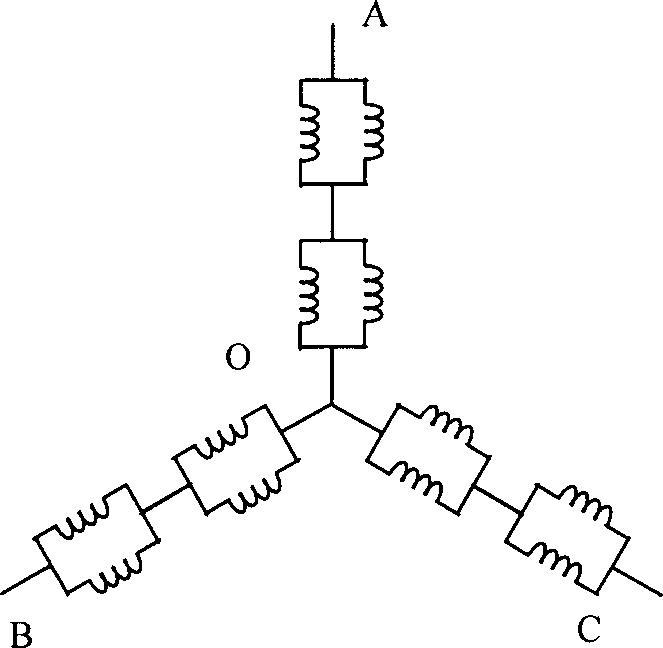

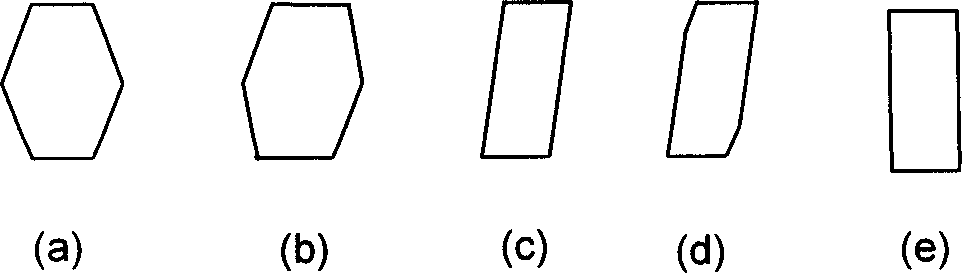

[0019] Such as figure 1 As shown, a flat permanent magnet linear synchronous motor includes a magnetic circuit structure and a mechanical structure. The magnetic circuit structure includes a primary composed of an iron core 7 and a winding 3, and a secondary composed of a magnetic steel 6 made of NdFeB permanent magnets and an electrical pure iron base plate 4 arranged on a base 5; the iron core 7 is to make with silicon steel laminations, with pressing plate 9, layering bar 11, compression screw rod 14 are compressed at two ends. The primary winding adopts a single-layer, full-pitch winding, and a star connection in series and parallel (see figure 2 ). The shape of the magnetic steel 6 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com