Preparation process of lithium aluminium hydride reduction

A technology of aluminum lithium hydride and aluminum lithium, which is applied in the direction of various metal hydrides, can solve the problems of unsafety and many by-products, and achieve the effect of simple production method, complete utilization and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 241.43g of aluminum chloride hexahydrate and 42.41g of lithium chloride, add water to dissolve, add a certain amount of sodium carbonate solution, wait until the precipitation is complete, put it aside for suction filtration, dry the solid and then calcinate at a high temperature of 500-600°C After decomposing for 4 hours, the oxide was obtained, the oxide was in the autoclave, and CaH was added 2 As a catalyst, at 180°C and 20kg / cm 2 After hydrogenation of the solid under hydrogen pressure for 4-5 hours, a mixed element of aluminum and lithium is obtained. Adding catalyst naphthalene and TiCl in the organic solvent tetrahydrofuran 4 , hydrogenation at normal temperature and pressure by introducing hydrogen gas for 4-5 hours, and the lithium aluminum hydride product can be obtained.

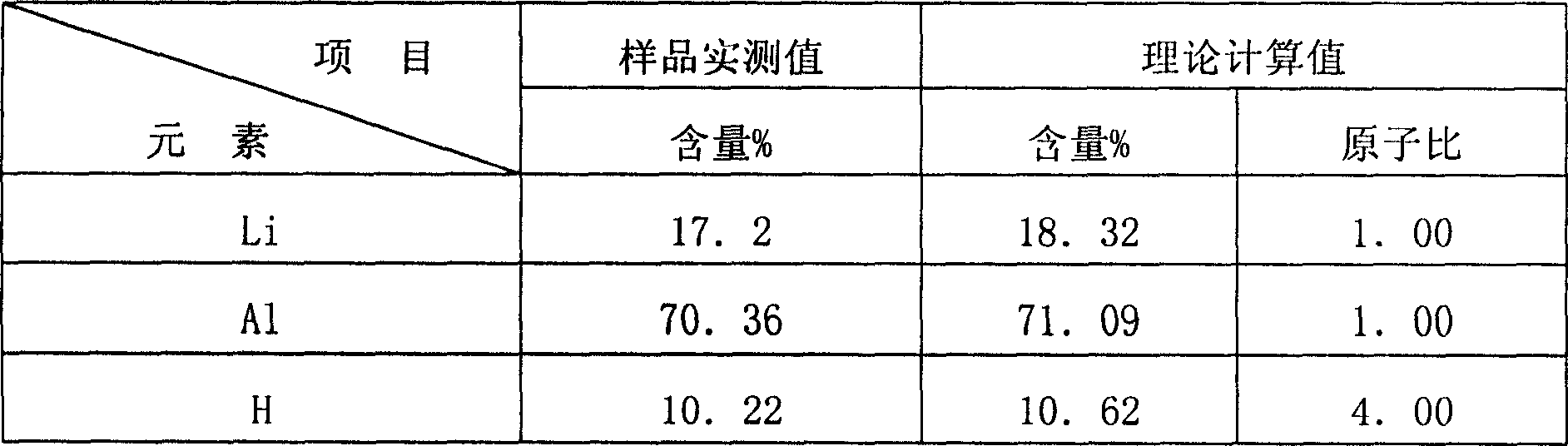

[0019] Product analysis: The content analysis of Li, Al and H was carried out on this product. The analysis of Li was carried out by atomic absorption method; the analysis of Al wa...

Embodiment 2

[0022] Weigh 241.43g of aluminum chloride hexahydrate and 42.41g of lithium chloride, add water to dissolve, add a certain amount of sodium oxalate solution, wait until the precipitation is complete, put it aside for suction filtration, dry the solid and then calcinate at a high temperature of 500-600°C After decomposing for 4 hours, the oxide was obtained, the oxide was in the autoclave, and CaH was added 2 As a catalyst, at 180°C and 20kg / cm 2 After hydrogenation of the solid under hydrogen pressure for 4-5 hours, a mixed element of aluminum and lithium is obtained. Adding catalyst naphthalene and TiCl in the organic solvent tetrahydrofuran 4 , hydrogenation at normal temperature and pressure by introducing hydrogen gas for 4-5 hours, and the lithium aluminum hydride product can be obtained.

Embodiment 3

[0024] Weigh 375g of aluminum nitrate and 69g of lithium nitrate, add water to dissolve, add a certain amount of sodium oxalate solution, wait until the precipitation is complete, put it aside for suction filtration, and after the solid is dried, it is calcined at 500-600°C for 4 hours and then oxidized. material, the oxide in an autoclave, and adding CaH 2 As a catalyst, at 180°C and 20kg / cm 2 After hydrogenation of the solid under hydrogen pressure for 4-5 hours, a mixed element of aluminum and lithium is obtained. Adding catalyst naphthalene and TiCl in the organic solvent tetrahydrofuran 4 , hydrogenation at normal temperature and pressure by introducing hydrogen gas for 4-5 hours to obtain the lithium aluminum hydride product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com