Preparation process of adhesive for high-speed machanical labelling

An adhesive and mechanical technology, which is used in the preparation of high-speed mechanical labeling adhesives, can solve the problems of poor rheology, difficult sizing, unstable viscosity storage, etc., so as to reduce production costs, improve rheology and performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

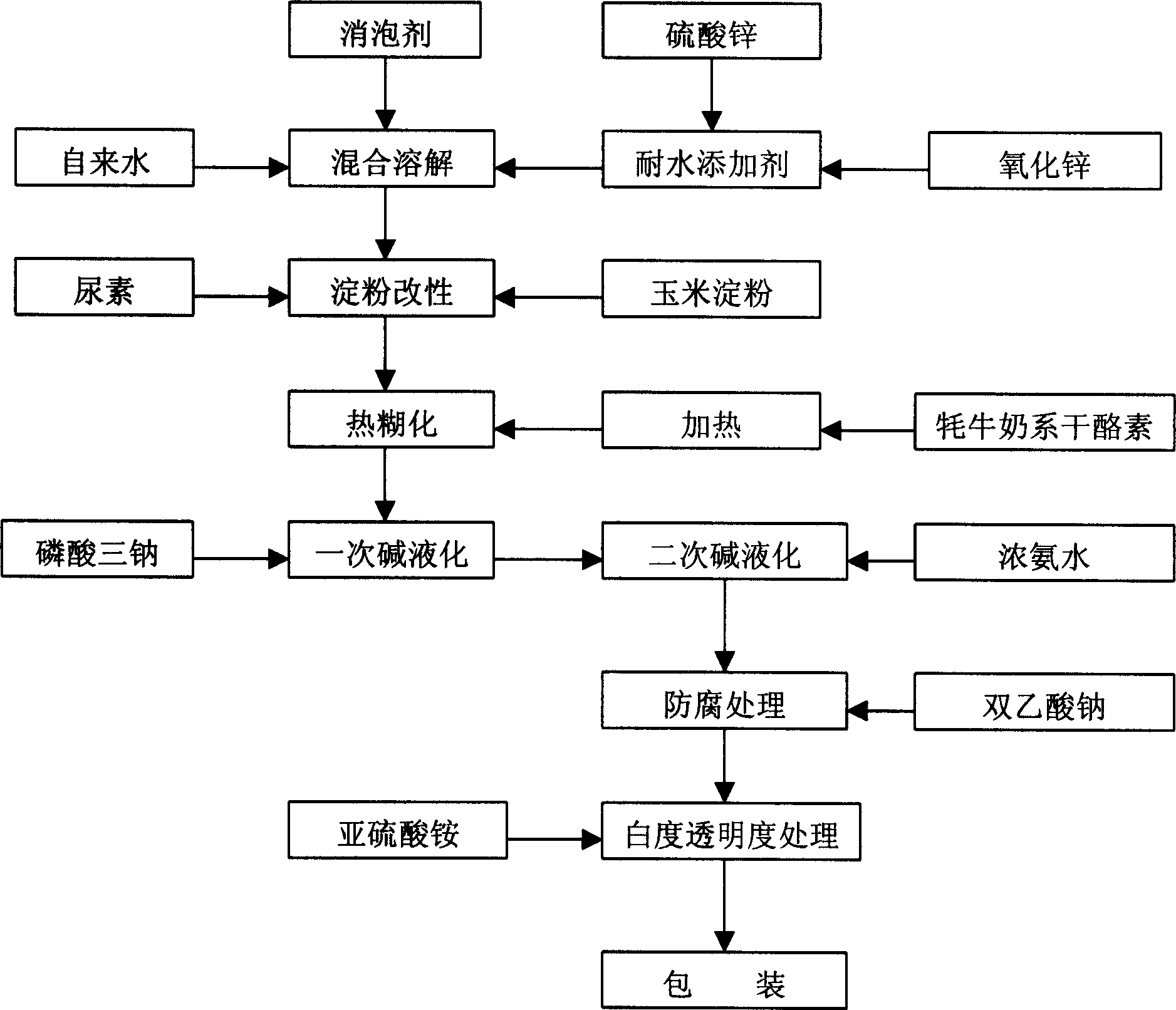

Image

Examples

Embodiment 1

[0016] Use Lanzhou Hualing brand yak milk series industrial refined first-grade casein, with a protein content of 85%, add 4kg of cross-linking agent and 2kg of defoamer to 300kg of tap water, heat up and stir to dissolve, add 60kg of urea and cornstarch at 40°C 10kg, stirred at 50°C for 30min to modify the starch, then added 120kg of yak milk casein, and heat gelatinized at about 75°C for 1.5h. Then lower the temperature to 65°C and add 6 kg of trisodium phosphate decahydrate, adjust the pH value of the system to 6.5-7.5 with a small amount of ammonia water, and liquefy for 30 minutes. Add 3kg of sodium diacetate antifungal agent to disinfect and sterilize for 10 minutes, cool down to 40°C, use 7kg of ammonium sulfite for rheological treatment, and unload to obtain 513kg of adhesive products with a total solid content of 48% and a viscosity of 80-90Pa·s. High-speed mechanical labeling in summer.

Embodiment 2

[0018] Use Lanzhou Hualing brand yak milk series industrial first-grade casein, with a protein content of 83%, add 4kg of crosslinking agent and 1.kg of defoamer to 350kg of tap water, heat up and stir to dissolve, add 100kg of urea at 45°C, 15kg of corn starch was modified by stirring at 50°C for 30 minutes, then 90kg of yak milk casein was added, and heat-gelatinized at about 75°C for 1 hour. Add 2kg of sodium diacetate as an anti-mold and fungicide, then cool down to 60°C, add 5kg of trisodium phosphate decahydrate, adjust the pH value of the system to 7-7.5 with concentrated ammonia water, and liquefy for 30 minutes. Use 6kg of ammonium sulfite to increase rheology , transparency and whiteness, 571kg of adhesive products were obtained from unloading, with a total solid content of 41% and a viscosity of 35-45Pa·s, suitable for high-speed mechanical labeling in winter.

Embodiment 3

[0020] Use industrial grade casein from yak milk produced in Xining, Qinghai, with a protein content of 84%, add 4kg of water-resistant additives and 2.5kg of defoamer to 350kg of tap water, heat up and stir to dissolve, add 100kg of urea and 12kg of cornstarch at 40°C, Stir at 50°C for starch modification for 30 minutes, then add 110kg of yak milk cheese, and heat and liquefy at about 75°C for 1.0h. Add 3kg of sodium diacetate as an antifungal agent, then cool down to 65°C and add 5kg of trisodium phosphate decahydrate, adjust the pH of the system to 6.5-7 with ammonia water, and liquefy for 60 minutes. When the temperature is lowered at 40°C, 6kg of ammonium sulfite is used for rheology, transparency, and whiteness treatment, and 592kg of adhesive products are obtained after unloading, with a total solid content of 45% and a viscosity of 60-70Pa·s, suitable for high-speed machinery in spring and autumn Labeling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com