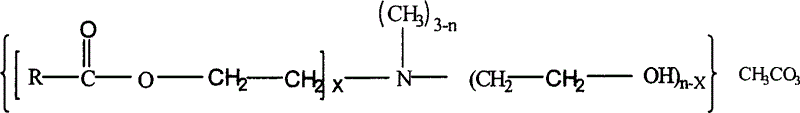

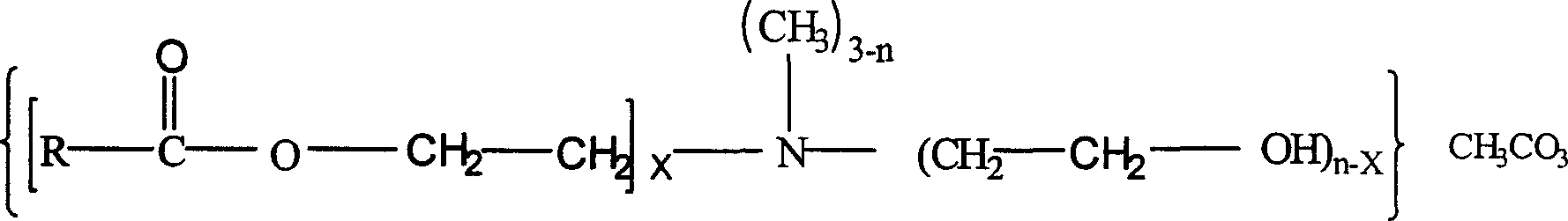

Quaternary ammonium salt in ester-amines and synthetic method

A synthesis method and technology of quaternary ammonium salts, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., to achieve excellent environmental compatibility and skin compatibility, improve grades, and facilitate use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 284g of stearic acid and add it to a 500mL four-necked bottle, stir and heat up to 100°C under N2 atmosphere, after all of them are melted, add 1g of alkylbenzenesulfonic acid and 75g of triethanolamine, and heat up to 180°C, The stirring speed was increased, and after 6 hours of reaction, the acid value of the product was measured to be 2.8 mgKOH / g, and the reaction was terminated.

[0026] Cool the reaction mixture to 80°C, stop feeding N 2 gas, add isopropanol 30g, dimethyl carbonate 45g to carry out quaternization reaction, react for 3 hours, record free amine content in the product is 1.8%, can stop reaction.

Embodiment 2

[0028] Take by weighing 284g stearic acid and join in the four-hole bottle of 500mL, under N 2 Stir under atmospheric conditions and heat up to 100°C. After all of them are melted, add 1g of alkylbenzenesulfonic acid and 60g of methyldiethanolamine, raise the temperature to 170°C, increase the stirring speed, and measure the acid value of the product after 7 hours of reaction. When it was 2.6 mgKOH / g, the reaction was terminated.

[0029] Cool the reaction mixture to 80°C, stop feeding N 2 gas, add isopropanol 30g, dimethyl carbonate 45g to carry out quaternization reaction, react for 2.5 hours, when the free amine content in the product is measured to be 1.7%, the reaction can be stopped.

Embodiment 3

[0031] Take by weighing 282g oleic acid and join in the 500mL four-necked bottle, under N 2 Stir under atmospheric conditions and heat up to 90°C, add 1g of alkylbenzenesulfonic acid and 75g of triethanolamine, raise the temperature to 160°C, increase the stirring speed, and react after 6 hours, when the acid value of the product is 3.0mgKOH / g, stop reaction.

[0032] Cool the reaction mixture to 60°C, stop feeding N 2 Gas, add isopropanol 30g, dimethyl carbonate 45g carries out quaternization reaction, after reacting for 3 hours, when recording free amine content in the product is 1.6%, can stop reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com