Electro-optical polarized polymer containing nano ferroelectric crystals, and preparation method

A technology of polarized polymers and nanocrystals, which is applied in the field of electro-optic polarized polymers and their preparation, can solve problems such as SBN and PZT single crystal difficulties, and achieve the effects of low cost, low optical loss and strong application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

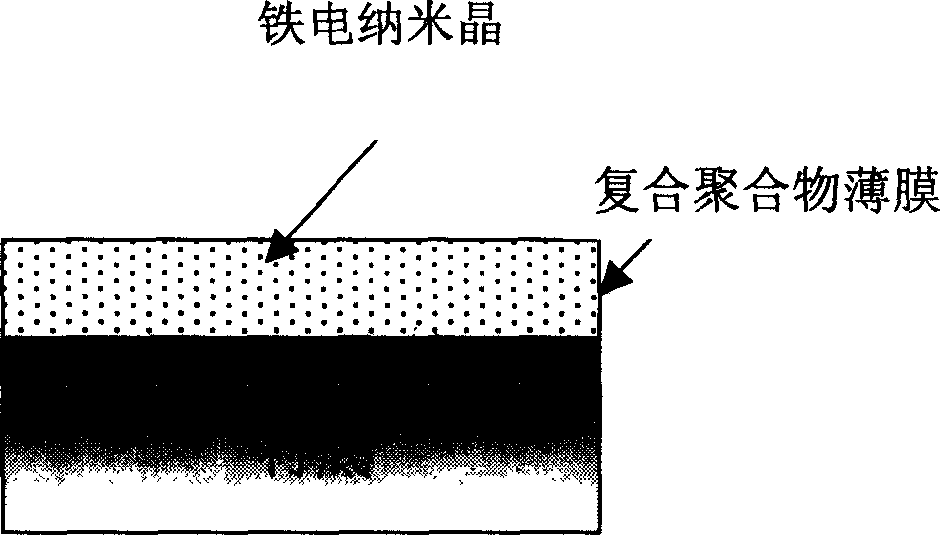

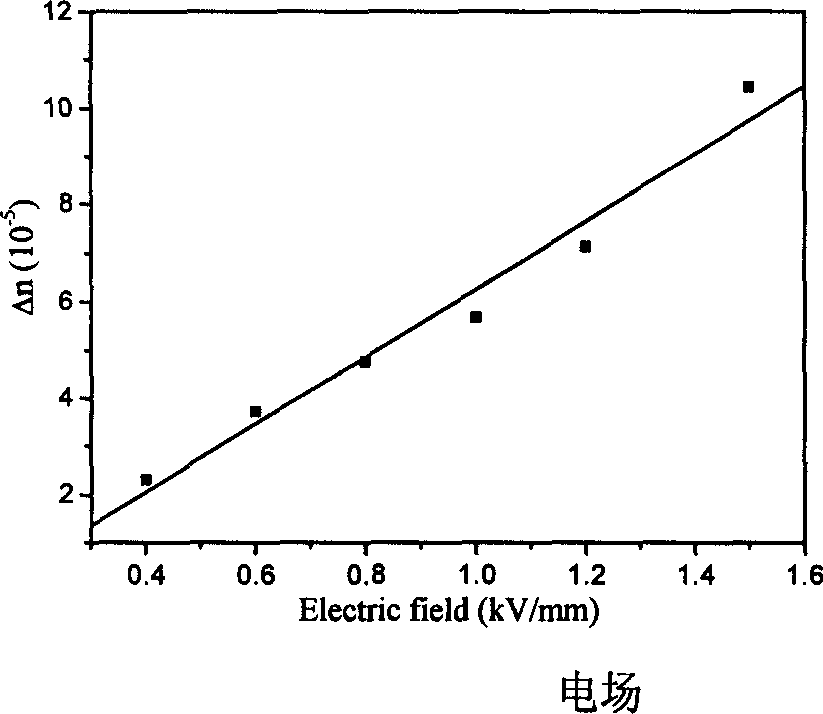

[0014] Selection of ferroelectric nanocrystalline materials: ferroelectric nanocrystalline materials: barium strontium niobate (Sr x Ba 1-x Nb 2 o 6 , x=0.25-0.75, SBN), lead zirconate titanate (Pb(Zr x Ti 1-x )O 3 , x=0-0.94, PZT), lanthanum-doped lead zirconate titanate (Pb 1-y La y )(Zr x Ti 1-x )O 3 , y=0.02-0.30, x=0-1.00, PLZT), barium titanate BaTiO 3 , lithium niobate LiNbO 3 Both are materials with large electro-optic coefficients (20-60pm / V). The invention makes use of its large electro-optic coefficient to make a special material.

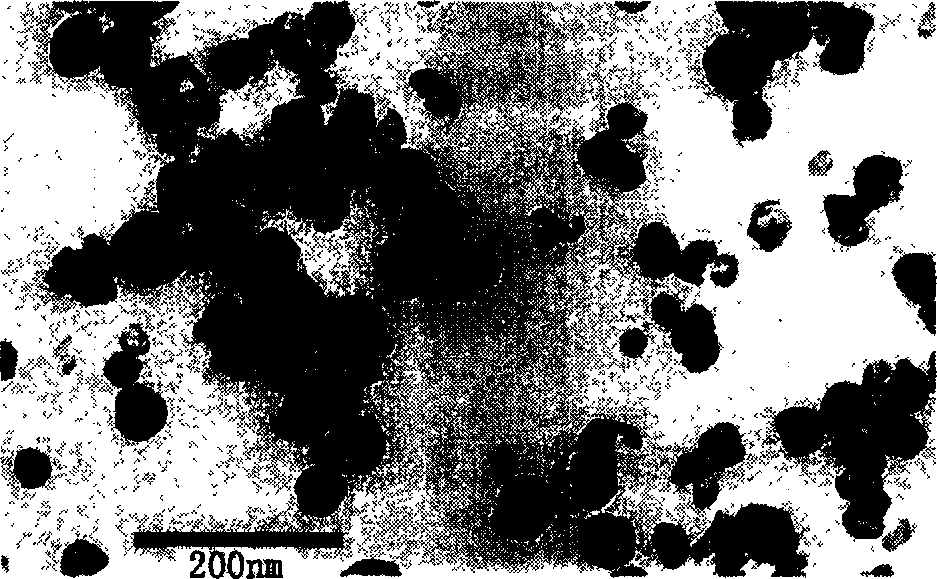

[0015] Ferroelectric nanocrystals are prepared by a precursor solution, the polymer matrix material is dissolved in a polar solvent, and the precursor solution and the polar solvent are placed on a single crystal silicon wafer or a platinum-coated silicon wafer, commercial ITO conductive glass, or quartz glass, etc. Composite polymer film preparation on the substrate material: deposit the film by spin-coating or dip-coating,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electro-optic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com