Nano level grating for polarization beam division / combination and method for making same

A manufacturing method and nano-grating technology, applied in diffraction grating, polarizing element, optics and other directions, can solve the problems of small grating area and insufficient grating line width, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

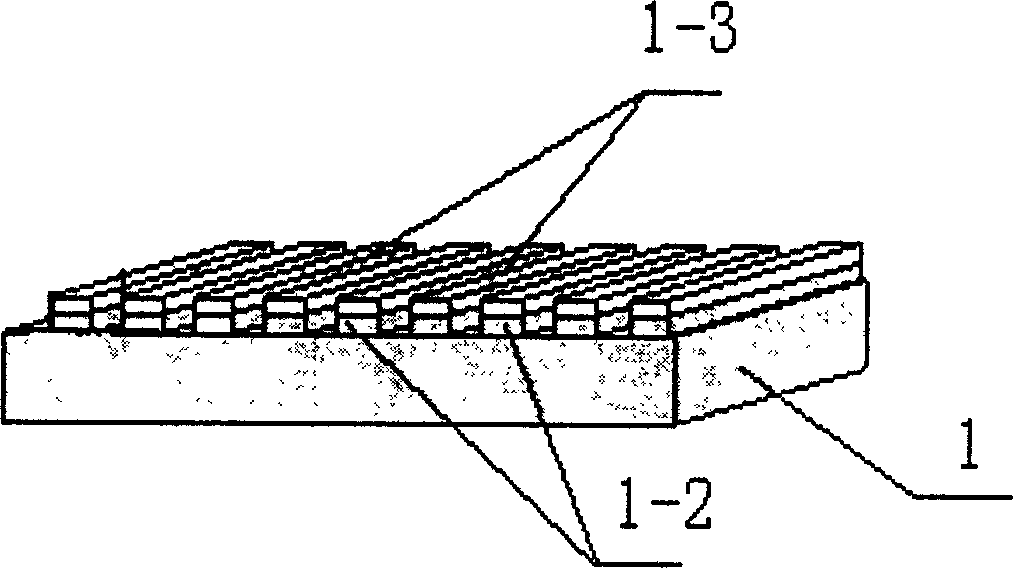

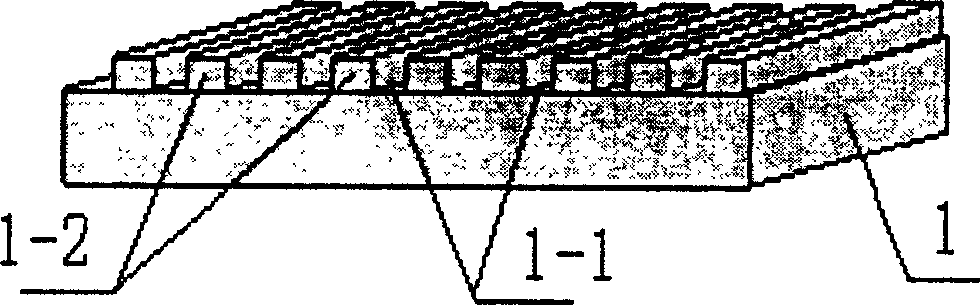

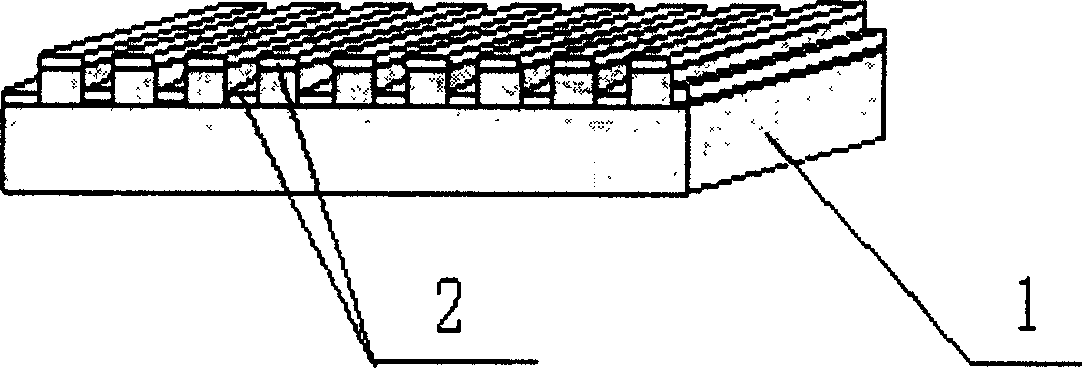

[0033] The main technical basis of the invention is to realize the ordinary nanoscale grating structure by using the synchrotron radiation X-ray photolithography process. The use of X-ray lithography to obtain nanostructures has a relatively mature process foundation in the laboratory, but in the process of practical application, the requirements of large area and uniformity put forward new requirements for the lithography process. By improving the lithography stepping device and in-depth study of the lithography process, the production of large-area nano-gratings can be realized and the uniformity of the microstructure can be ensured. Compared with the current deep ultraviolet laser holographic exposure method, its line width can be improved from about 200nm to about 100nm. Compared with the electron beam exposure method, the area size of the material can be expanded from the order of millimeters to the order of 10 centimeters. We use synchrotron radiation light sources to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com