Coil circuit board and surface mounted type coil element

A surface mount type, coil component technology, applied in coil manufacturing, electrical components, transformer/inductor coil/winding/connection, etc., can solve the difficulty of removing resist and base conductor layer, increase of DC resistance, pattern peeling And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

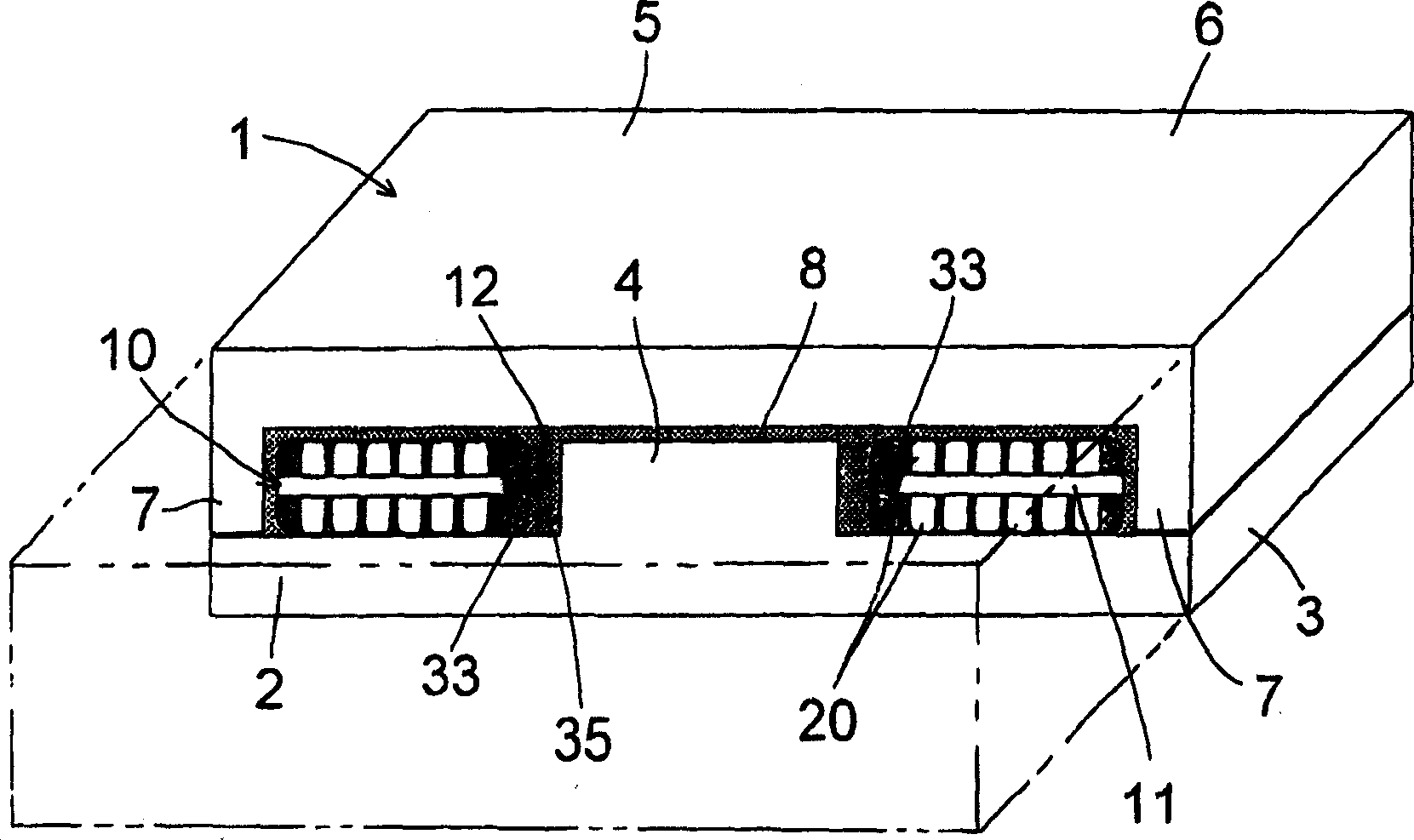

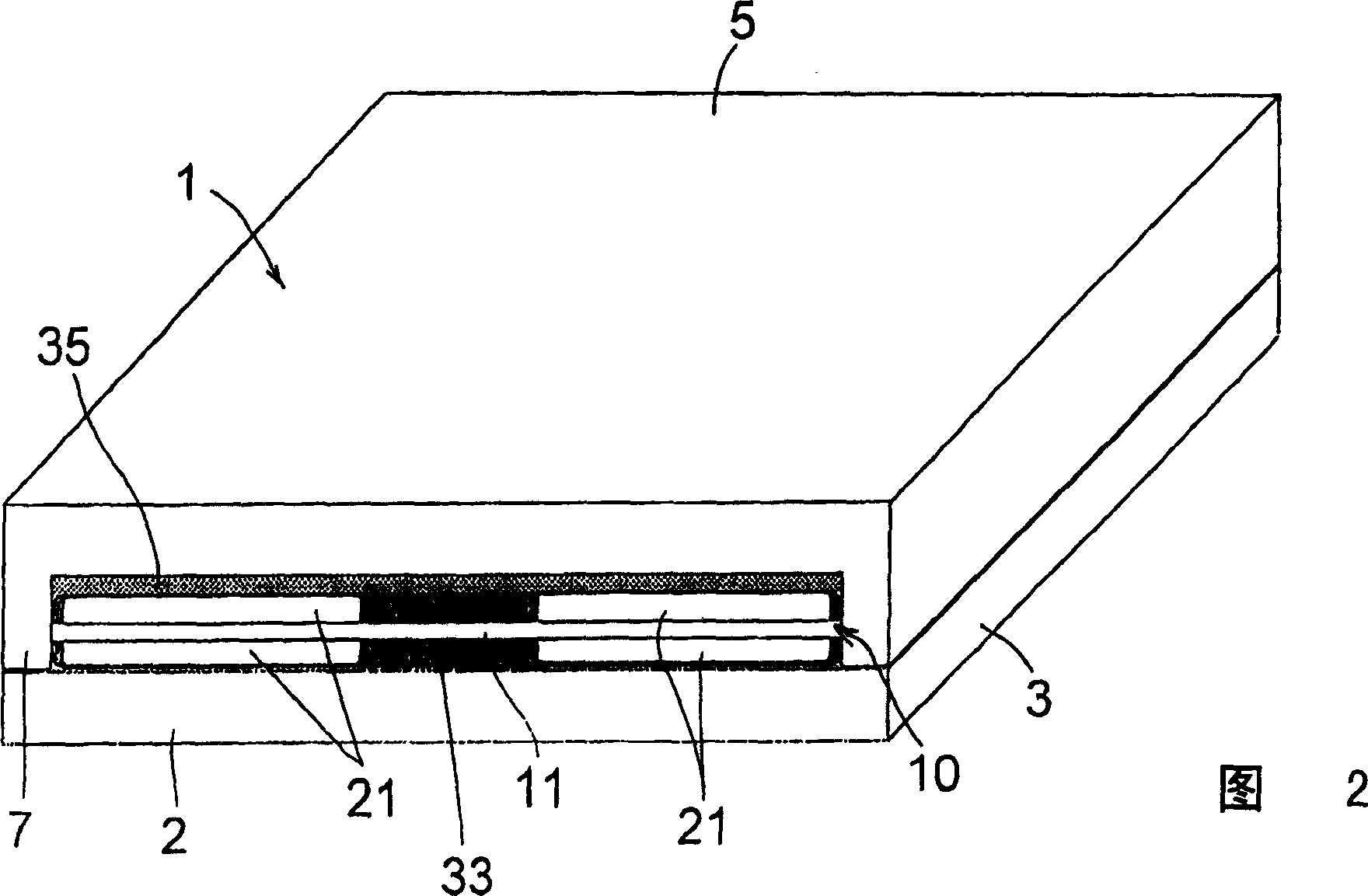

[0067] In the following, the coil circuit board and the surface-mounted coil component according to the present invention will be described in detail.

[0068] For a glass fiber cloth plate (a plate made of glass fiber cloth impregnated with BT resin) with a thickness of 60 μm and a connection hole and a through hole for the insertion of the central convex part, the upper and lower surfaces are formed by electroless plating with a thickness of 0.1 to 10 μm. A Cu film of 1 μm was used as the base conductor layer. Secondly, form a photosensitive electrodeposited resist film and use photolithography to form a spiral pattern that will become a coil conductor on both sides of the glass fiber cloth, with a voltage of not more than 15A / dm 2 Electroplating was carried out for about 20 minutes at a high current to form a Cu conductor pattern with a height of 35 μm and a width of 35 μm. After peeling off the resist mask for selective plating, the base conductor layer was etched, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dc resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com