Environmentally friendly track rubber, and its production method and track construction method using same

A construction method and an environment-friendly technology, which is applied in the construction of plastic runways and the field of polyurethane runway glue, can solve the problems of plastic runway materials that are not environmentally friendly, people's health injuries, and social anxiety, etc., to achieve simple transportation and construction, good construction effects, The effect of complete polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The environment-friendly runway rubber of the present embodiment is produced from the raw materials of following parts by weight:

[0056] Polyether diol 400, polyether triol 60, TDI40, PAPI60, filler 100, and additives made of the following raw materials in parts by weight: modifier 60, ester plasticizer 100, oil softener 100 , Phosphoric acid pH regulator 5, UV absorber (light stabilizer) 2, aging agent 1.5.

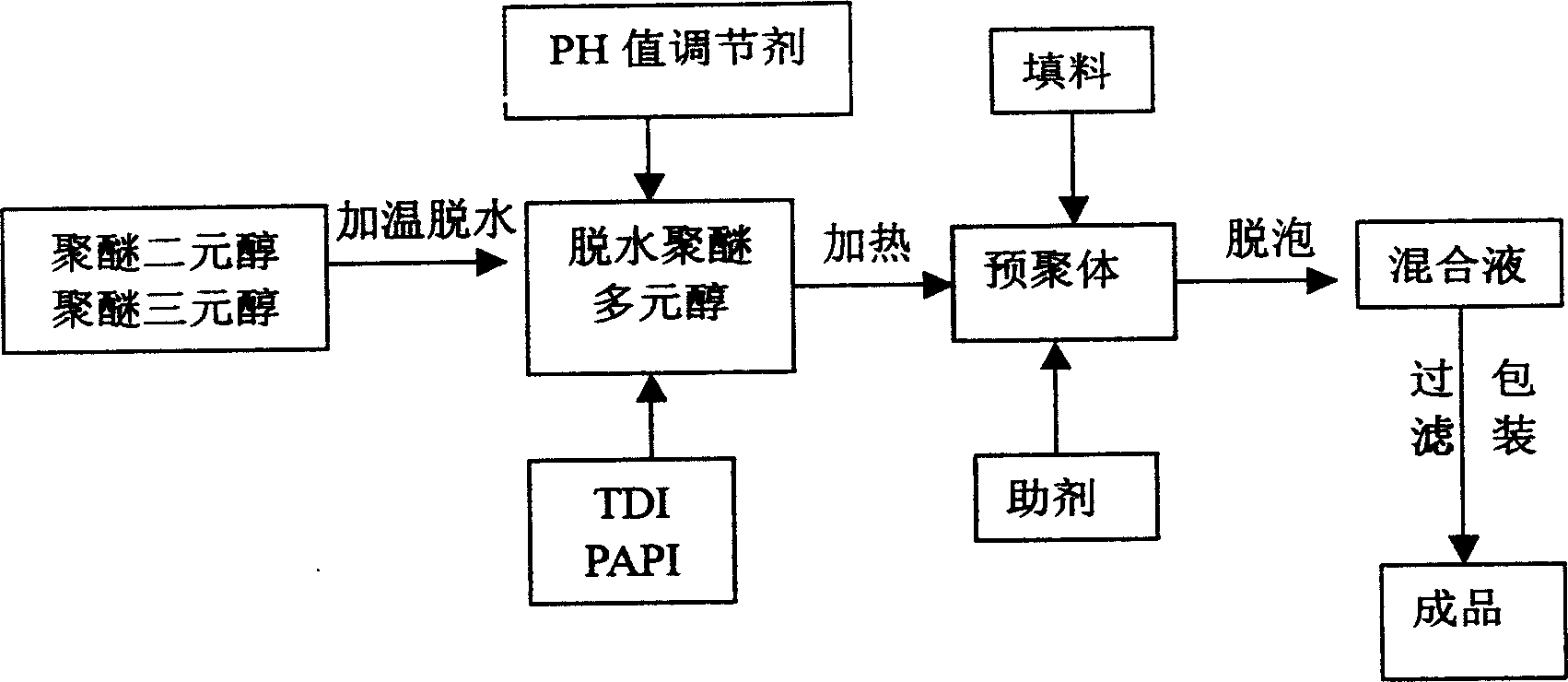

[0057] Its production method refers to figure 1 As shown, it consists of the following production process:

[0058] (1) Polyether diol and polyether triol are heated to 110°C for dehydration;

[0059] (5) Mix the above-mentioned polyether polyol after dehydration with TDI and PAPI according to the above ratio and heat it to 80°C to polymerize it into a prepolymer, control the polymerization time to 2 hours, and add a phosphoric acid pH value regulator during the polymerization The pH value of the adjustment reaction is 6.5-7.5, preferably 7;

[0060] (6) Mix t...

Embodiment 2

[0070] The environment-friendly runway rubber of the present embodiment is produced from the raw materials of following parts by weight:

[0071] Polyether diol 500, polyether triol 50, TDI50, PAPI100, pH regulator 10, filler 120, and additives consisting of the following raw materials: bentonite modifier 50, ester plasticizer 150, Oil softener 80, light stabilizer 3, aging agent 1 part, and part of wetting agent.

[0072] Its production method refers to figure 1 As shown, it consists of the following production process:

[0073] (1) heating polyether diol and polyether triol to 120°C for dehydration;

[0074] (2) The above-mentioned polyether polyol after dehydration is mixed with TDI and PAPI according to the amount of the above-mentioned raw materials and heated to 75°C to polymerize it into a prepolymer. The polymerization time is controlled to be 2 hours, and the pH value is adjusted by adding a pH regulator. neutral;

[0075] (3) Mix the filler and additives with the...

Embodiment 3

[0085] The environment-friendly runway rubber of the present embodiment is produced from the raw materials of following parts by weight:

[0086] Polyether diol 450, polyether triol 55, TDI45, PAPI90, bentonite modifier 55, BINT (phthalate) ester plasticizer 130, paraffin oil softener 90, pH regulator 7. Light stabilizer 2.5, inorganic filler 110 parts.

[0087] Its production method refers to figure 1 As shown, it consists of the following production process:

[0088] (1) heating polyether diol and polyether triol to 115°C for dehydration;

[0089] (5) The above-mentioned polyether polyol after dehydration is mixed with TDI and PAPI according to the above ratio and heated to 80°C to polymerize it into a prepolymer. The polymerization time is controlled to be 2 hours, and a pH regulator is added during the reaction to adjust its pH value;

[0090] (6) Mix the filler and additives with the prepolymer, and then vacuumize to -0.09MPa, so that the bubbles in the mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com