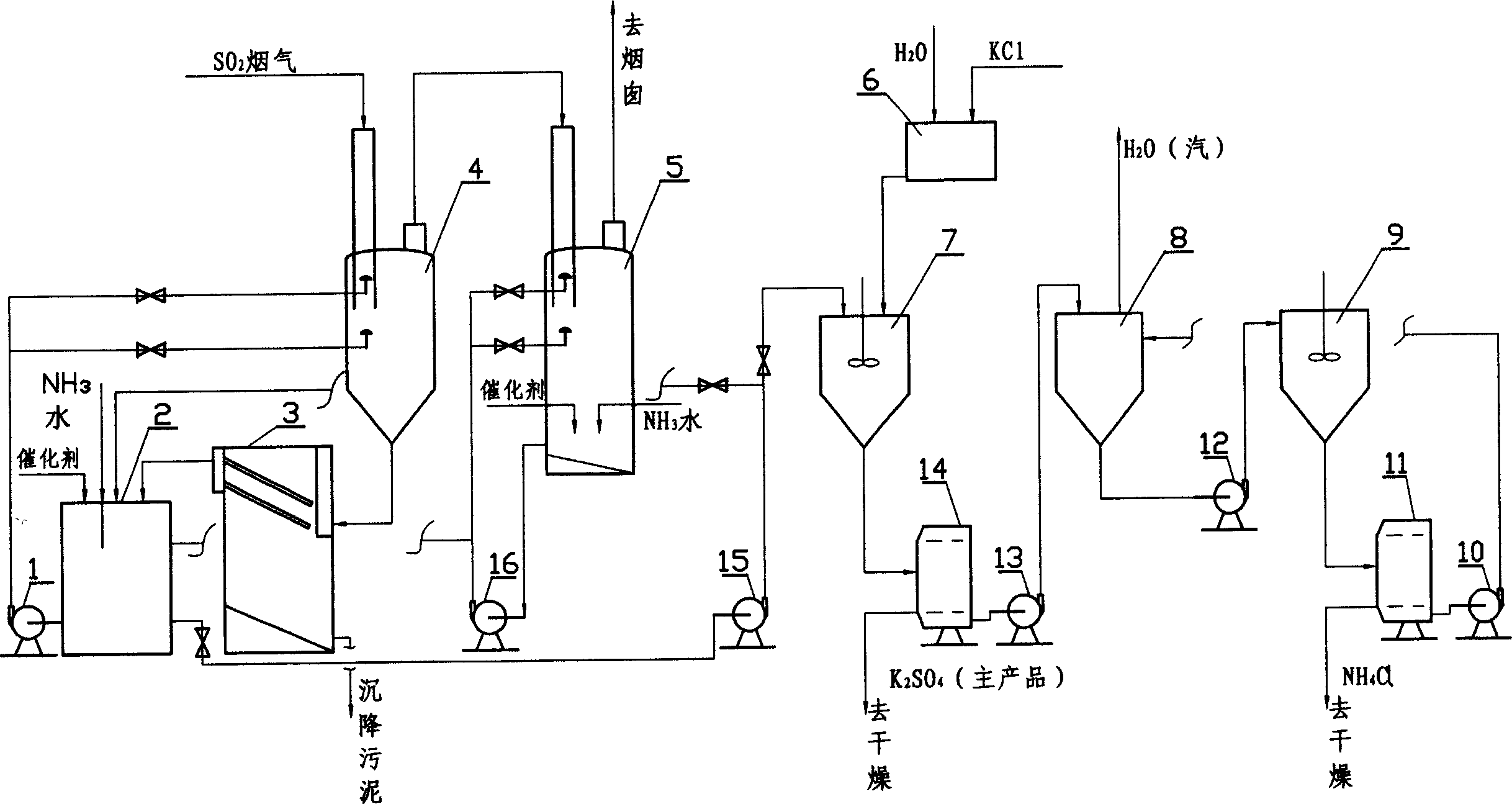

Method and apparatus for directly preparing K2SO4 after low concentration SO2 smoke gas absorbing oxidation

A K2SO4, SO2 technology, applied in the direction of sulfate/bisulfate preparation, etc., can solve the problems of high material consumption and high price, and achieve the effects of low production cost, low raw material consumption and energy consumption, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: (the process operating condition of the present embodiment is the same as the prior art, and the device is described in claim 2)

[0015] Dust below 100°C ≤ 200mg / Nm 3 , SO 2 4 ) 2 SO 3 , NH 4 HSO 3 , (NH 4 ) 2 SO 4 solution, the density of mother liquor is 1.2~1.24g / cm 3 , the alkalinity is 1.5~2.0tt°. SO 2 The flue gas collides with the reverse jet rotating liquid in a section of turbulent reverse spray swirling liquid absorption oxidation tower (4), forming a turbulent foam zone, and the gas-liquid film mass transfer surface is renewed quickly, SO 2 It is chemically absorbed as a sub-salt and due to the presence of oxygen in the gas stream, the catalytic effect of the catalyst is converted into (NH 4 ) 2 SO 4 , SO 2 After passing through a section of turbulent reverse spray liquid absorption oxidation tower (4), the absorption rate>80%, the absorbed SO 2 The produced nitrite is oxidized to (NH 4 ) 2 SO 4 , accounting for 98% of the tot...

Embodiment 2

[0017] Basically with embodiment 1. The difference is: a section of Fe +3 The amount of catalyst added is 0.1% of the solid content; the second stage S 2 o 3 -2 Catalyst addition is 0.2% of solid content; The 500g / L (NH 4 ) 2 SO 4 The aqueous solution is transported to the metathesis reactor (7) through the pump (15), and the saturated KCl solution is stirred and reacted at a temperature of 75°C to form K 2 SO 4 crystallization.

Embodiment 3

[0019] Basically with embodiment 1. The difference is: a section of Fe +3 The amount of catalyst added is 0.15% of the solid content; the second stage S 2 o 3 -2 Catalyst addition is 0.3% of solid content; The 550g / L (NH 4 ) 2 SO 4 The aqueous solution is transported to the metathesis reactor (7) through the pump (15) and reacts with the powdery solid at 90° C. to form K 2 SO 4 crystallization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com