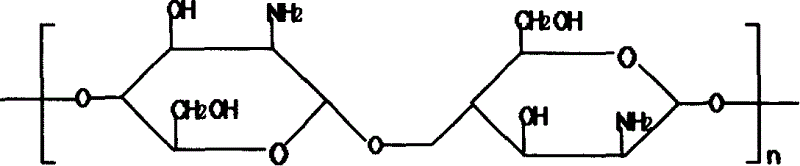

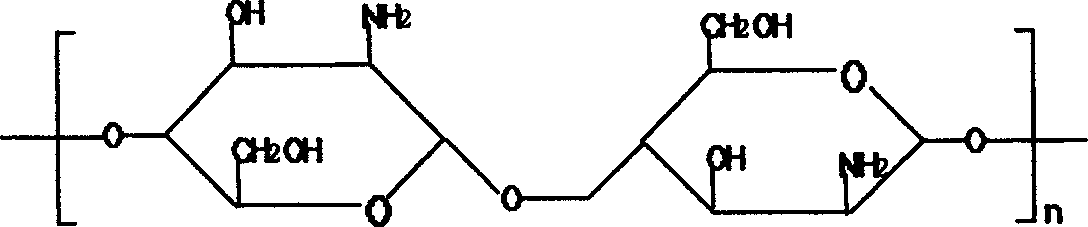

Absorptive medical chitosan suture and its producing method

A technology of chitosan and suture, which is applied in the field of medical surgical suture materials, can solve the problems of susceptibility to allergies, decreased mechanical strength, and poor absorbability, and achieves safe and easy-to-obtain solvents, high tensile strength, and high degree of deacetylation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Dissolve 60 g of chitosan with a viscosity of 800 mPa S and a degree of deacetylation of 90% in 1.8% acetic acid, add 6 g of urea, and then add 0.4% sodium acetate by weight of chitosan , 1.4% sorbitol, and 0.3% absolute ethanol are prepared into a slurry with a concentration of 3.0%. Stir at 20°C for 3-4 hours to form a uniform chitosan spinning slurry. The slurry is filtered with 300-mesh poplin cloth, the pressure is controlled at 0.2-0.3Mpa, and then vacuumized for degassing. The defoamed slurry is transported to the spinning cap with a metering pump. The hole diameter of the spinning cap was 0.07 mm, and the number of holes was 120 holes. The coagulation bath is a mixed solution of sodium hydroxide and ethanol. The content of sodium hydroxide is 4.8%. Continue to stretch 1.3 times in hot water at ℃, and the total stretch ratio is 1.43. The stretched fibers are first washed with deionized water until neutral, and then soaked with absolute ethanol. Af...

Embodiment 2

[0026] Example 2: Dissolve 60 g of chitosan with a viscosity of 2000 mPa S and a degree of deacetylation of 91% in 1.7% acetic acid, add 15 g of urea, and then add 0.8% sodium acetate by weight of chitosan , 1.0% sorbitol, and 0.8% absolute ethanol are prepared into a slurry with a concentration of 3.0%. Stir at 20°C for 3-4 hours to form a uniform chitosan spinning slurry. The slurry is filtered with 300-mesh poplin cloth, the pressure is controlled at 0.2-0.3Mpa, and then vacuumized for degassing. The defoamed slurry is transported to the spinning cap with a metering pump. The hole diameter of the spinning cap is 0.08 mm, and the number of holes is 160 holes. The coagulation bath is a mixed solution of sodium hydroxide and ethanol. The content of sodium hydroxide is 10%. Continue to stretch 1.4 times in hot water at ℃, and the total stretch ratio is 1.54. The stretched fibers are first washed with deionized water until neutral, and then soaked with absolute ethanol. Aft...

Embodiment 3

[0027] Example 3: Dissolve 60 g of chitosan with a viscosity of 3000 mPa S and a degree of deacetylation of 92% in 1.5% acetic acid, add 30 g of urea, and then add zinc acetate with a weight of 1.2% of chitosan , 0.6% sorbitol, and 1.5% absolute ethanol are prepared into a slurry with a concentration of 3.0%. Stir at 20°C for 3-4 hours to form a uniform chitosan spinning slurry. The slurry is filtered with 300-mesh poplin cloth, the pressure is controlled at 0.2-0.3Mpa, and then vacuumized for degassing. The defoamed slurry is transported to the spinning cap with a metering pump. The hole diameter of the spinning cap is 0.10 mm, and the number of holes is 200 holes. The coagulation bath is a mixed solution of sodium hydroxide and ethanol, the content of sodium hydroxide is 20%, the temperature of the coagulation bath is 3.0°C, stretch 1.1 times in hot water at 70-80°C after leaving the coagulation bath, and then stretch it at more than 90°C Continue to stretch 1.4 times in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com