Anti-static floor tile

An anti-static, floor tile technology, applied in building materials and other directions, can solve the problems of complex construction, short life, poor moisture resistance of cement particle board, etc., and achieve the effect of good toughness and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enhance thermal stability, smooth stability and lubricity, a small amount of lead stearate, barium stearate, stearic acid, tri-salt, di-salt, etc. can also be added on the basis of the original ingredients.

[0014] In order to make the floor tile color of the present invention coordinate with the color of the whole room, a small amount of carrier color matching agent can also be added on the basis of the original ingredients;

[0015] In order to enhance the finish, a small amount of plasticizer is added on the basis of the original ingredients.

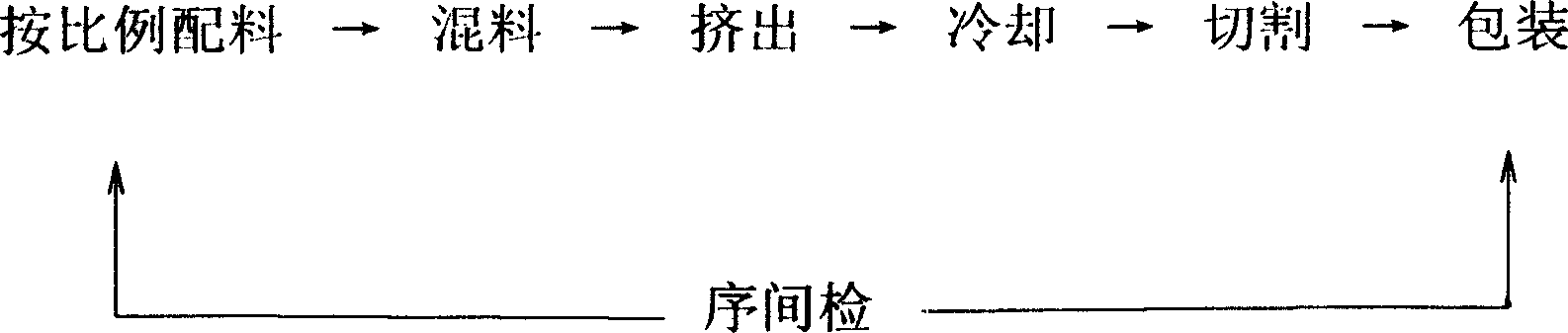

[0016] The brick-making process of the invention is a conventional brick-making process, and its heating temperature is preferably controlled at 120-170°C. The main production equipment is twin-screw extruder unit, high and low temperature mixing tank, cutting machine, and mould.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com