Acrylic ester core-shell polymer

A technology of acrylate and alkyl acrylate, applied in the field of acrylate core-shell polymers, which can solve problems such as poor core-shell binding force, poor compatibility, and poor impact properties of blends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Preparation of alkyl acrylate polymer

[0032]Add 800 grams of deionized water, 0.5 grams of sodium dodecylbenzenesulfonate, 80 grams of butyl acrylate, and 2 grams of hexamethylene diacrylate into a polymerization kettle equipped with a thermometer, a stirrer, a nitrogen gas introduction device, and a monomer feeding device. alcohol esters. The temperature of the reactant was raised to 70° C. with stirring, and nitrogen gas was continuously blown in. After the reaction was initiated, continuously add the pre-emulsion containing 800 gram deionized water, 10 gram sodium dodecylbenzenesulfonate, 680 gram butyl acrylate, 18 gram hexanediol diacrylate and 7.5 gram ammonium persulfate, about Added within 2 hours. After the dropwise addition, the reaction was continued for 2 hours to obtain an alkyl acrylate polymer latex (A) with a particle diameter of 200 nanometers.

[0033] 2) Preparation of a copolymer of alkyl acrylate-methyl methacrylate

[0034] Add 0.3 grams o...

Embodiment 2

[0051] The preparation process is similar to that of Example 1, except that the amount of methyl methacrylate added in the process 3) in the preparation of the methyl methacrylate polymer is 247 grams. The maximum temperature rise during this process was about 3°C.

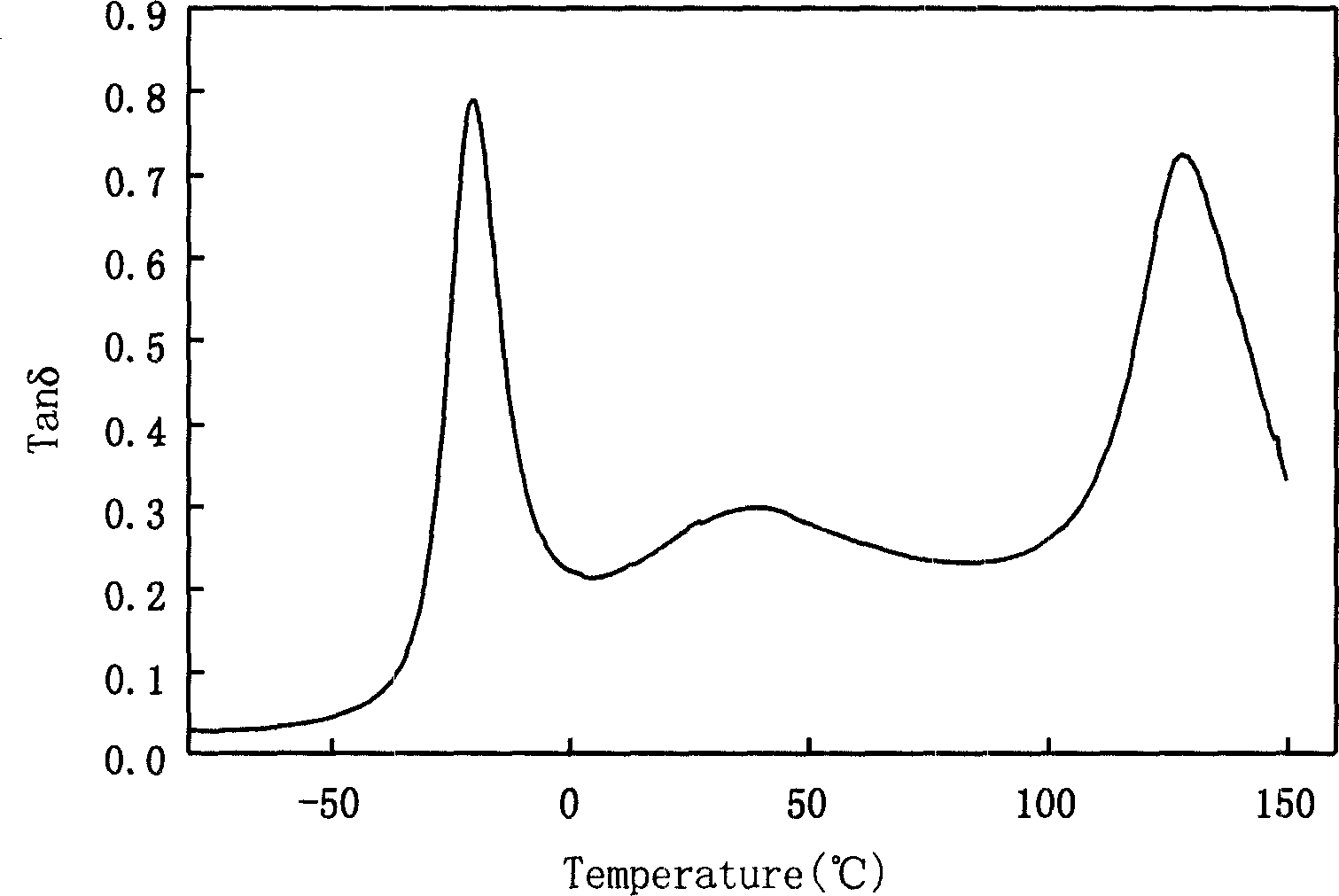

[0052] The acrylate core-shell polymer prepared in this example is prepared into a polyvinyl chloride blend according to the preparation process in Example 1. The performance test results are shown in Table 1, and the dynamic mechanical thermal analysis spectrum of the acrylate core-shell polymer is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com