Red anthraquinone dispersion dye

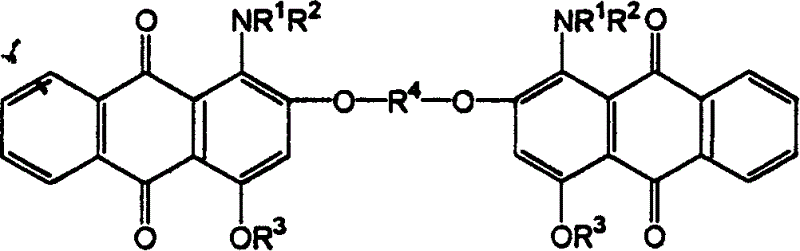

A disperse dye and red technology, applied in the direction of hydroxyanthraquinone dyes, etc., can solve the problems of dye post-processing troubles, increase dye cost, increase reaction steps, etc., and achieve the effect of novel structure, less reaction steps, and good sublimation fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In a 100 ml three-necked flask, add 65 ml of dimethyl sulfoxide solvent, 2.28 g of bisphenol A and 2 g of sodium hydroxide, stir and heat the bisphenol A until it dissolves. Then, add 7.36 grams of 1-amino-2-bromo-4-hydroxyanthraquinone, raise the temperature to 90-150°C, and react for 6-10 hours. After the reaction, cool, filter, wash the product until neutral, dry, and prepare Obtain red anthraquinone disperse dye products.

[0024] The structure of the product was determined and confirmed by mass spectrometry (mass spectrometer: HP 1100LC-MSD) and nuclear magnetic resonance (nuclear magnetic resonance instrument: VarianINOVA400M NMR):

[0025] After the synthesized product is dissolved in chloroform, do APCl mass spectrum, its molecular ion peak is: e / m=702

[0026] H a

H b

H c

H d

H e

H f

H g

δ

(ppm)

6.46(2H)

8.37(2H)

7.77(4H)

8.33(2H)

7.11(2H)

7.36(2H)

1.76(2...

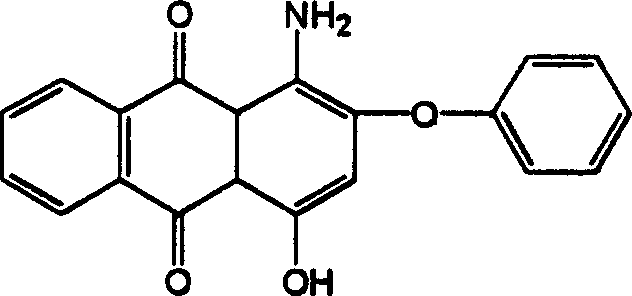

Embodiment 2

[0031] In a 100 ml three-neck flask, add 80 ml of mixed xylene solvent, 1.1 g of hydroquinone, and 2 g of sodium hydroxide, and stir at room temperature until the hydroquinone is dissolved. Then, add 7.50 grams of 1-amino-2-bromo-4-hydroxyanthraquinone, raise the temperature to 90-150°C, and react for 6-10 hours. After the reaction, cool, filter, wash with water until neutral, and dry to obtain Red anthraquinone disperse dye.

[0032] Use above-mentioned mass spectrometer and nuclear magnetic resonance instrument to measure, confirm that its structure is:

[0033]

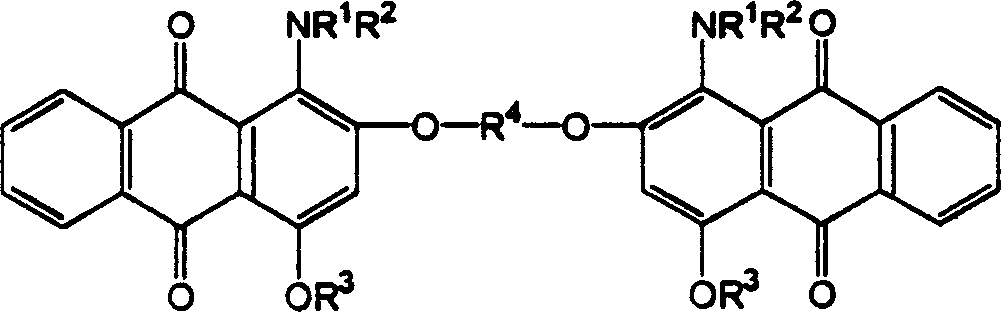

Embodiment 3

[0035] In a 100 ml three-necked flask, add 2.50 g of bisphenol S, 70 ml of mixed dichlorobenzene solvent and 3 g of potassium hydroxide, and heat under stirring until the bisphenol S dissolves. Then, add 7.65 grams of 1-amino-2-bromo-4-hydroxyanthraquinone, raise the temperature to 90-150°C, and react for 6-10 hours. After the reaction, cool, filter, wash with water until neutral, and dry to obtain Red anthraquinone disperse dye.

[0036] Equally, measure with above-mentioned mass spectrometer and nuclear magnetic resonance instrument, confirm that its structure is:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com