Energy saving spraying distillation type seawater desalination method under negative pressure and equipment

A technology of negative pressure distillation and equipment, which is applied in chemical instruments and methods, energy wastewater treatment, water/sewage treatment, etc., can solve the problems that the treatment cost per ton of water cannot be reduced, cannot be promoted, and the cost is high, so as to facilitate vaporization Evaporation and condensation speed are fast, and the effect of reducing conversion cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

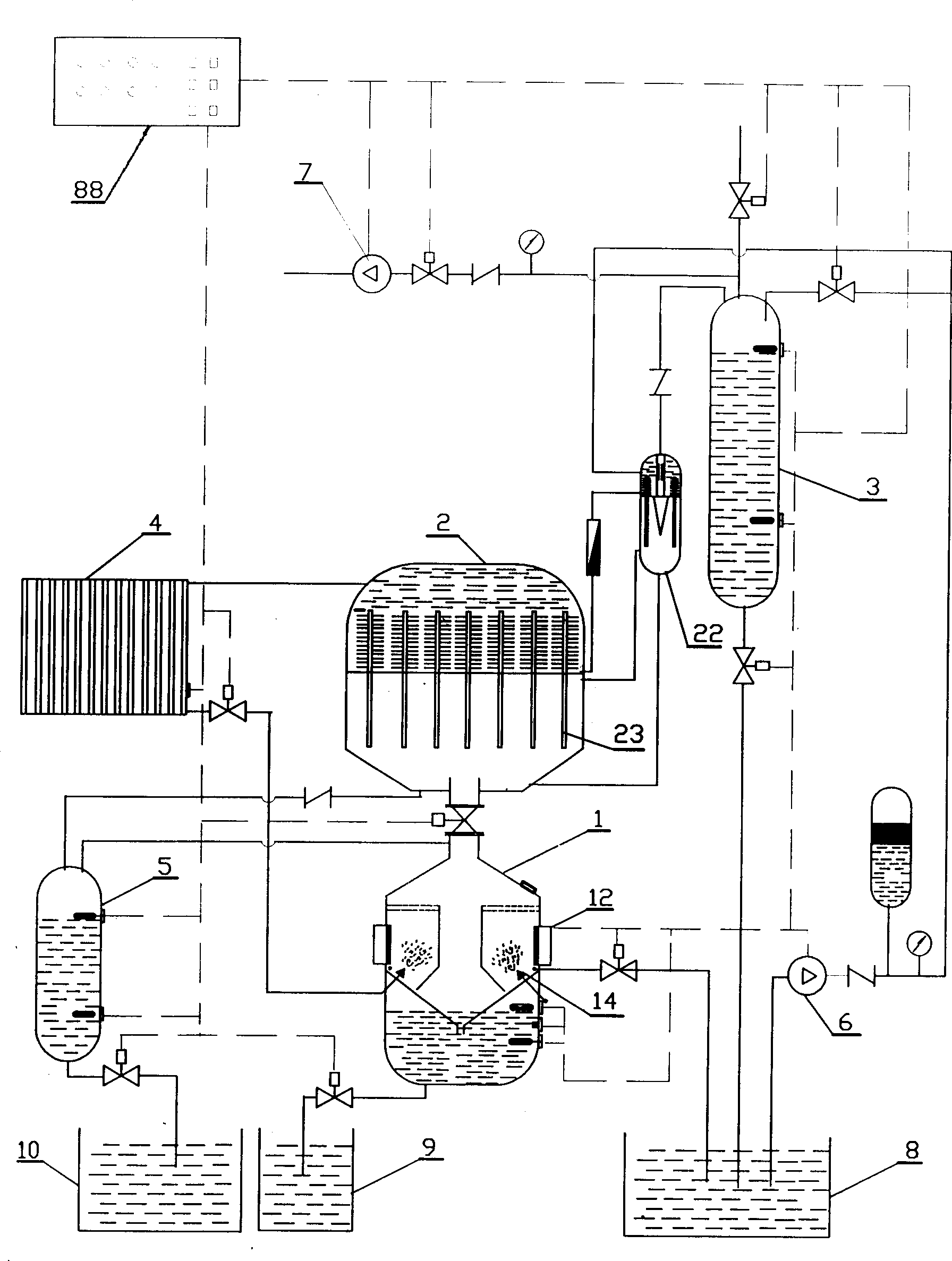

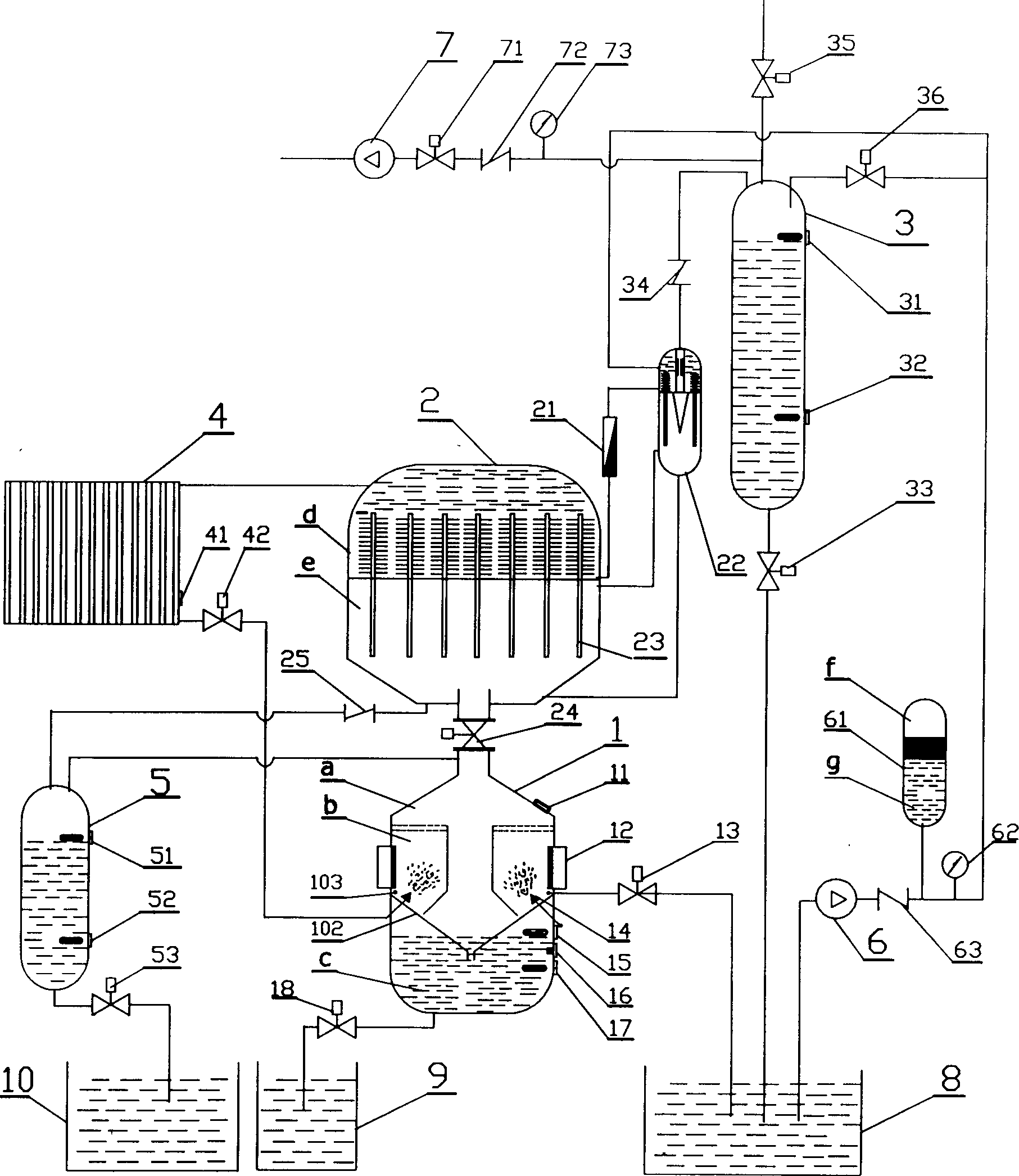

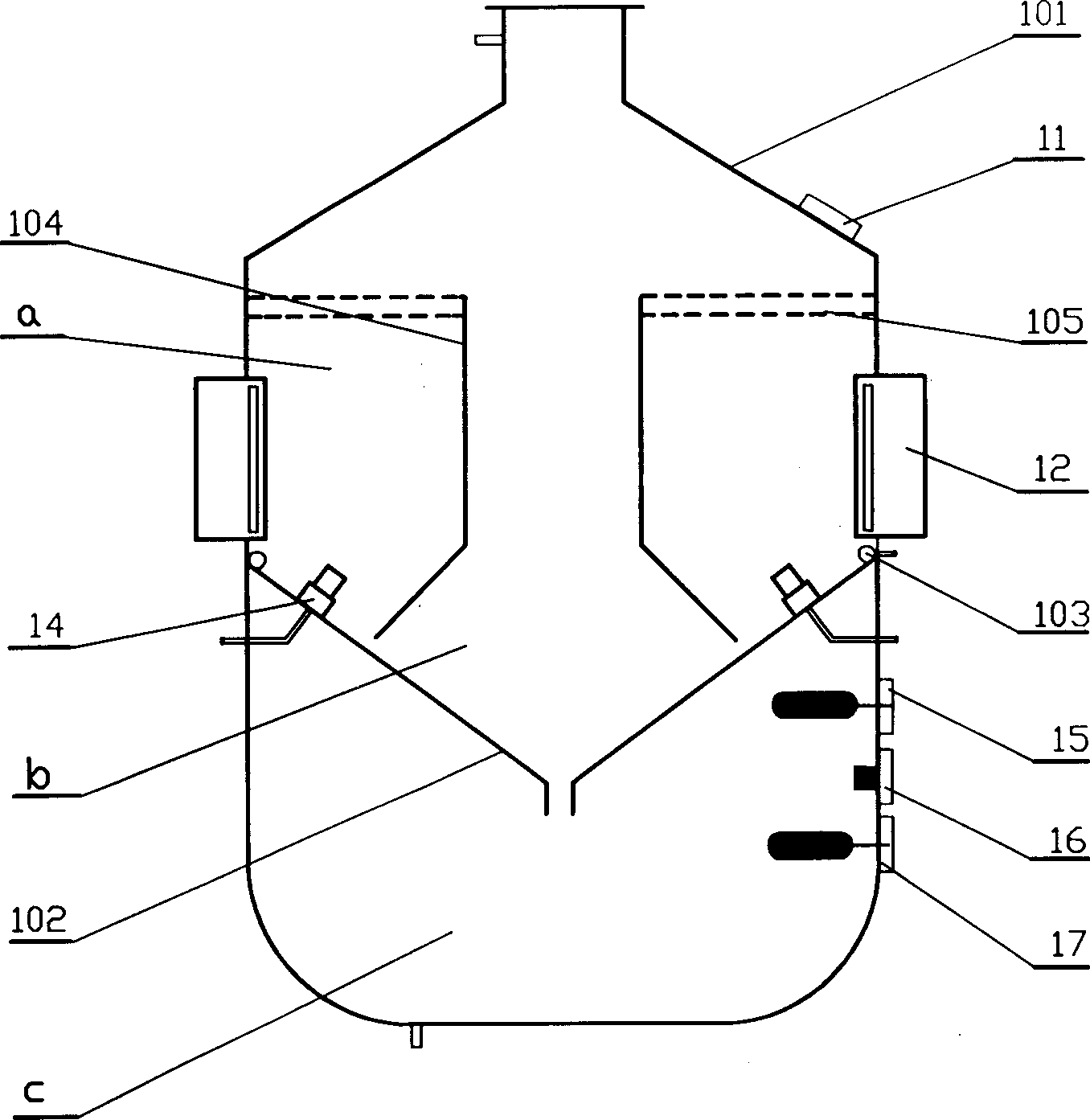

[0044] Earlier raw water pool 8 and dense salt pool 9 are filled with seawater, and fresh water pool 10 is filled with fresh water. Press the start button and the automatic control system enters the program control of the water injection process: open the solenoid valve 42, start the pressure pump 6 to work, and the water in the raw water pool 8 is pressed into the pressure storage tank 61, the cooling area of the condensation tank 2 and the solar heater 4 inside and spray out from the nozzle 14. When the bottom water level of the evaporation tank rose to the upper liquid level sensor 15, the solenoid valve 42 was closed and the pressure pump 6 was stopped. At this moment, the cooling area of the condensation tank and the inside of the solar heater were all filled with water, and the water injection process ended. The automatic control system enters the program control of negative pressure formation: open the solenoid valve 71, start the vacuum pump 7 to work, the air in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com