Lamellar lipophilic modified clay, ABS nanometer compound material and their preparation method

A nanocomposite material and lipophilic technology, which is applied in the field of layered lipophilic modified clay, ABS nanocomposite materials and their preparation methods, can solve the problems of limited dispersion and limited effect, and improve mechanical strength , reduce the cost of additives, and have the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

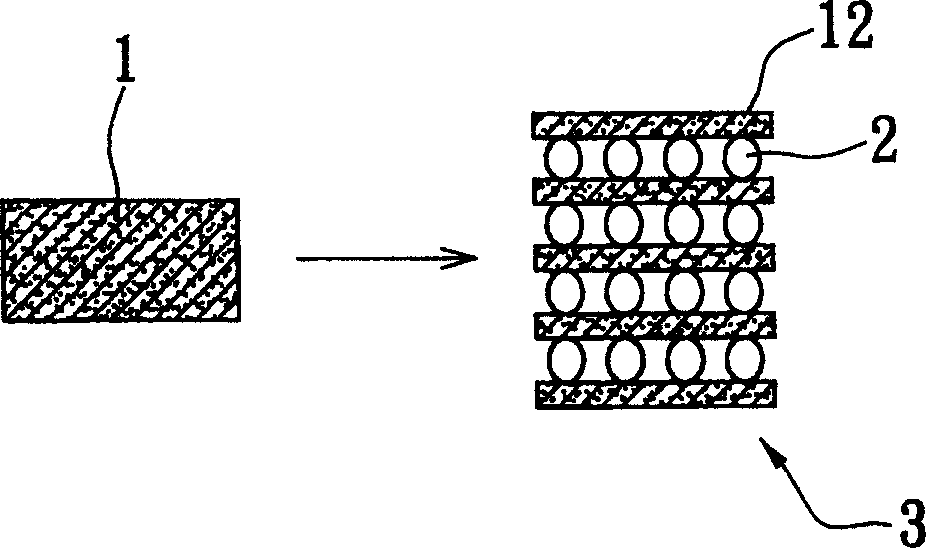

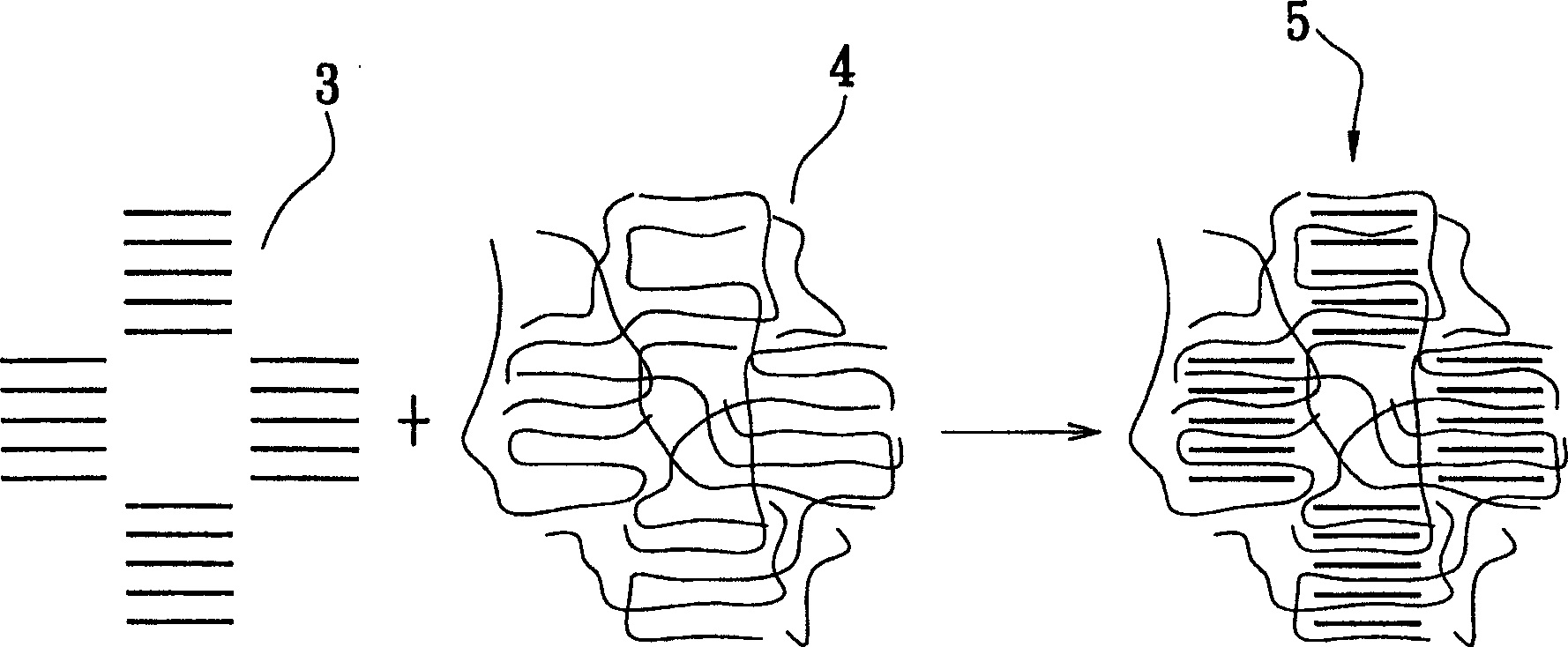

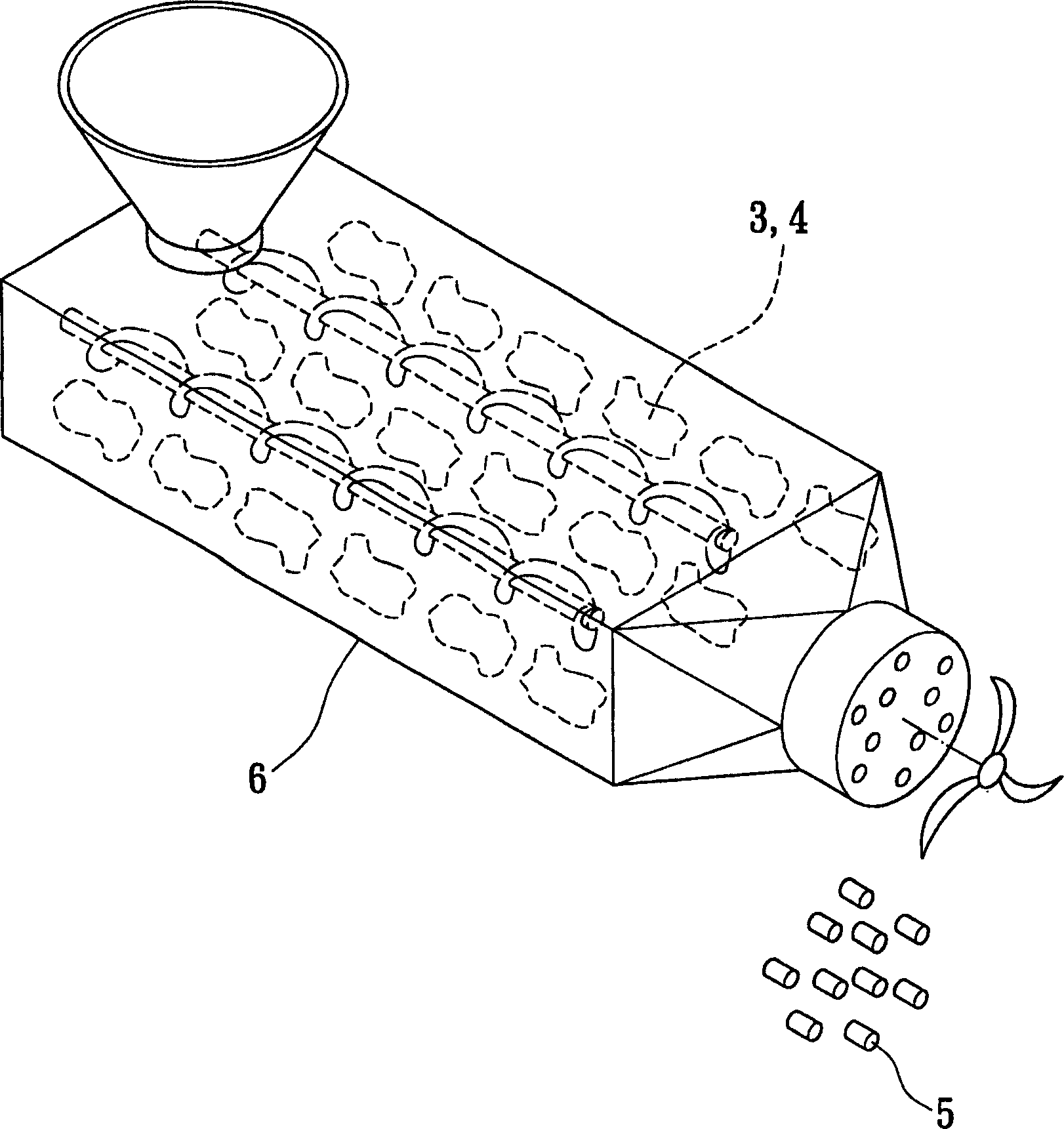

[0021] In a specific embodiment of the present invention, the modification preparation method of the lipophilic functional group modified clay is:

[0022] Take the inorganic layered montmorillonite PK-805 produced by Baikang Nano Technology Co., Ltd., with a cation exchange equivalent of 98meq / 100g, add water and stir for 10-12 hours, and configure it as a suspension solution of 25-40% by weight to make the clay swell Moisten; take cetyltrimethylammonium bromide, about 40-50% by weight relative to the inorganic layered montmorillonite PK-805, dissolve it into an aqueous solution, and slowly drop into the aforementioned inorganic layered montmorillonite PK-805 805 suspension solution and stirred overnight; after stirring, filter the precipitate; wash the precipitate repeatedly with distilled water and then dry it at 80°C; grind the dried precipitate with a ball mill until the particle size of the powder is about 10 -6m, namely, the lipophilic functional group-modified clay of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com