Prepn process of hydroprocessing catalyst

A hydrogenation treatment and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of easy generation of harmful mist, complex production process, and fast catalyst deactivation, etc., to achieve effective It is beneficial to metal dispersion, simplifies the preparation process, and improves the effect of interaction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Industrial-grade powdered molybdenum oxide (containing MoO 3 96.8w%) 134.0g add 530g (containing TiCl 3 7.5w%) titanium trichloride aqueous solution, stirred for 55 minutes and then filtered, the filter cake was set aside, and the filtrate was kept. Take by weighing 500g the silicon-alumina dry rubber powder (containing SiO2) that contains burnt residue and is 69.8w%. 2 9.3%), 92.0g industrial-grade powdered basic nickel carbonate (containing NiO 56.3w%), 12g asparagus powder, and mix homogeneously. Mix the wet filter cake with 150g water to make slurry, add it to the above solid powder mixture as evenly as possible, knead for 30 minutes, then add 140mL filtrate, knead for 90 minutes, and extrude the obtained plastic body into Φ0.82mm bars on the extruder This strip was dried at 80°C for 6 hours and activated in a roasting furnace at 550°C for 3 hours to obtain this example.

Embodiment 2

[0017] The molybdenum oxide in embodiment 1 is used 175g tungsten oxide (containing WO 3 98.3w%) instead, namely the cost example.

Embodiment 3

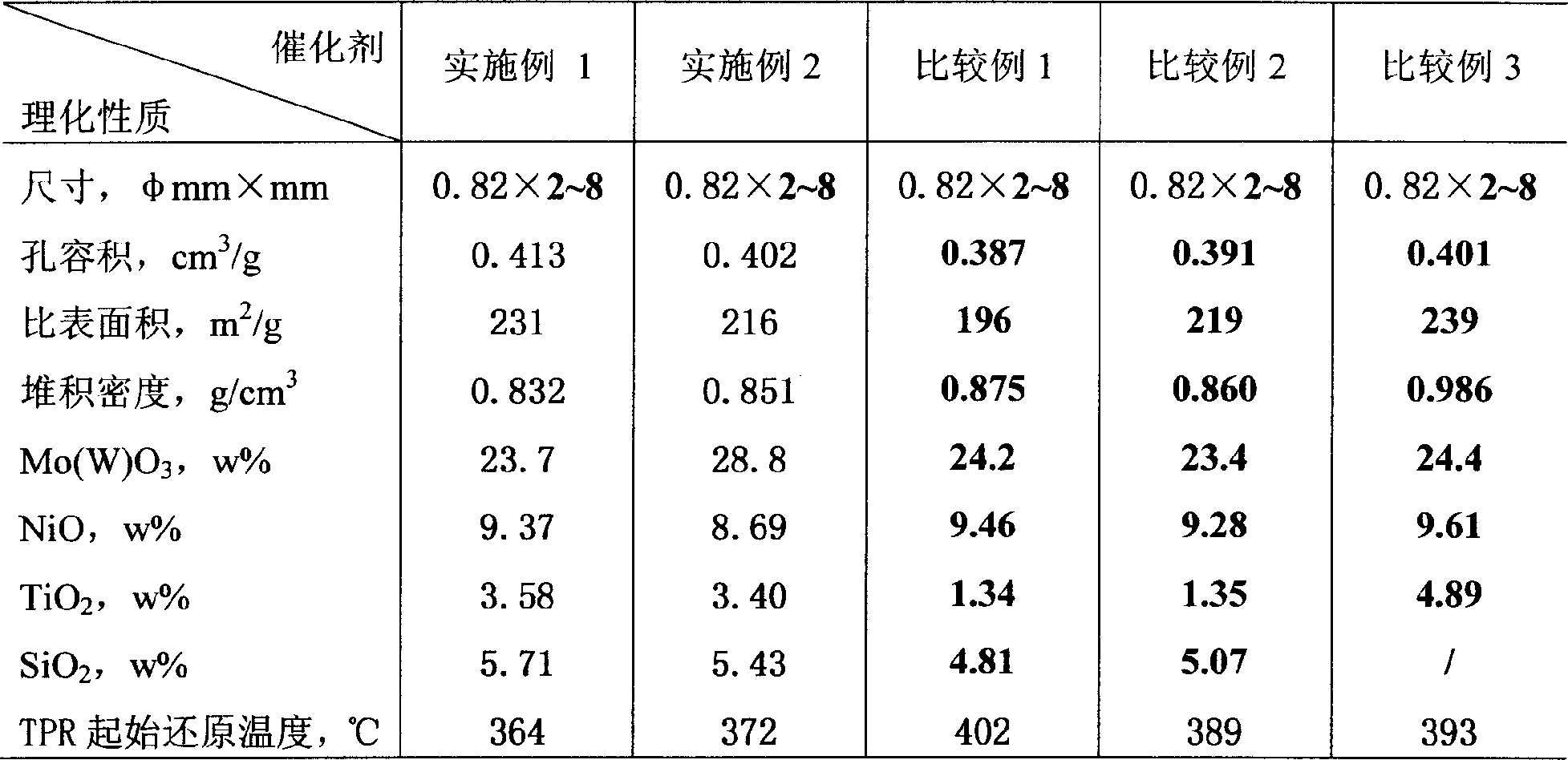

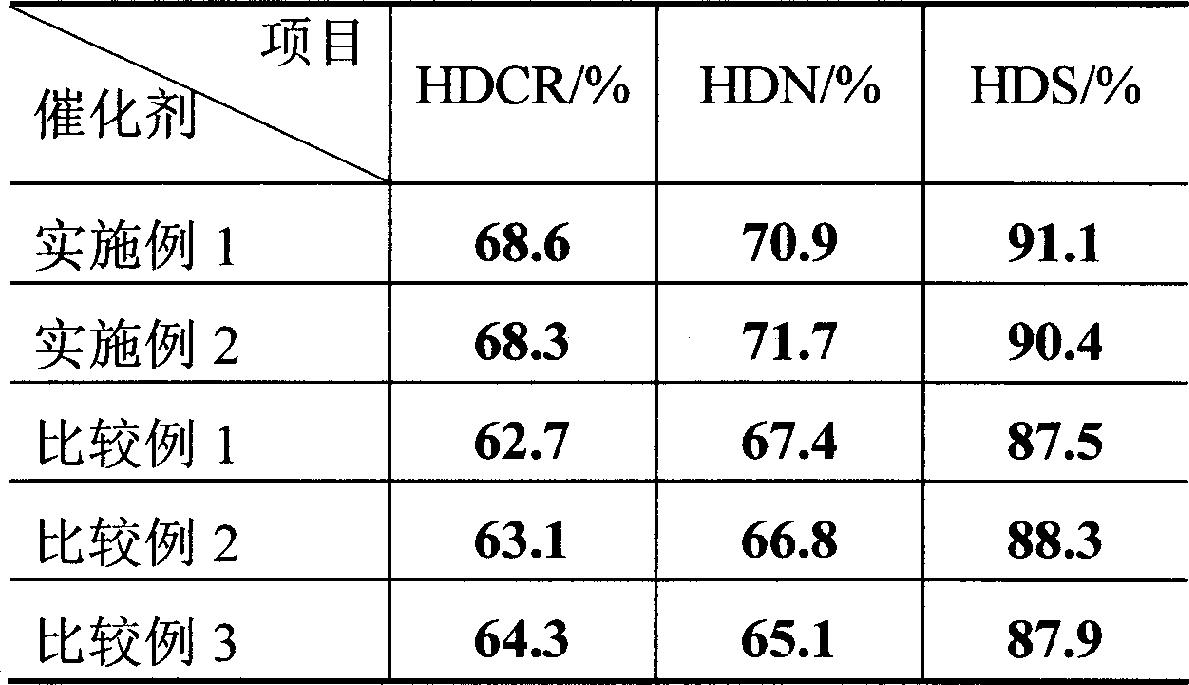

[0025] This example is the physical and chemical properties and activity evaluation results of the above catalysts.

[0026] The physical and chemical properties of the catalysts are listed in Table 1.

[0027] The properties of raw oil used for evaluation are shown in Table 2.

[0028] When evaluating catalysts, hydrogen and feed oil are mixed and passed through the catalyst bed from top to bottom, first through the hydrodesulfurization catalyst, and then through the catalysts of the above examples, in one pass mode, and the hydrodesulfurization catalyst is the same batch of industrial products. The process conditions used to evaluate the catalysts in each case are the same, which are: hydrogen partial pressure, 14.6MPa; reaction temperature, 400°C; total liquid hourly space velocity, 0.40h -1 ; Hydrogen oil ratio (v / v), 1000. The volume of the reactor is: φ25mm×2000mm. Catalyst loading volumes are: hydrodesulfurization catalyst, 120cm 3 ; Catalysts of the above examples,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com