Metallization method for producing integrated circuit copper interconnecting wire by separating bipolar acid chemical plating

An integrated circuit and electroless plating technology, applied in the field of electroless plating, can solve problems such as unusable, unsuitable for industrial applications, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

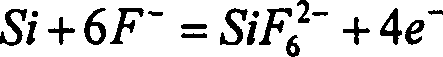

Method used

Image

Examples

Embodiment 1

[0024] The acidic solution is 1mol / l copper sulfate, 20wt% hydrofluoric acid, nitric acid and deionized water are added dropwise to adjust the pH of the solution to 0.2. The cathode of the silicon substrate is placed on the surface of the barrier layer facing the anode with a distance of 5mm, and the temperature of the acid solution during electroless plating is 50°C.

Embodiment 2

[0026] The acidic solution is 0.45mol / l copper nitrate, 10wt% hydrofluoric acid, adding deionized water to adjust the pH of the solution to 5, the silicon substrate cathode is placed on the surface of the barrier layer facing away from the anode, the distance is 0mm, the temperature of the acidic solution during electroless plating is 70°C.

Embodiment 3

[0028] The acid solution is 0.45mol / l copper sulfate, 8wt% hydrofluoric acid, adding deionized water to adjust the pH value of the solution to 3, the silicon substrate cathode is placed on the surface of the barrier layer of the anode, and the distance is 1mm. During electroless plating, the acid solution The temperature is 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com