Preparation for nanometer anhydrous wolframic acid powder

A tungsten trioxide powder and nanotechnology, applied in the direction of tungsten oxide/tungsten hydroxide, etc., can solve the problems of high cost of surfactants, unsuitability for large-scale powder production, complex reaction process, etc., and achieve simple and easy control of the reaction process, The effect of low cost and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

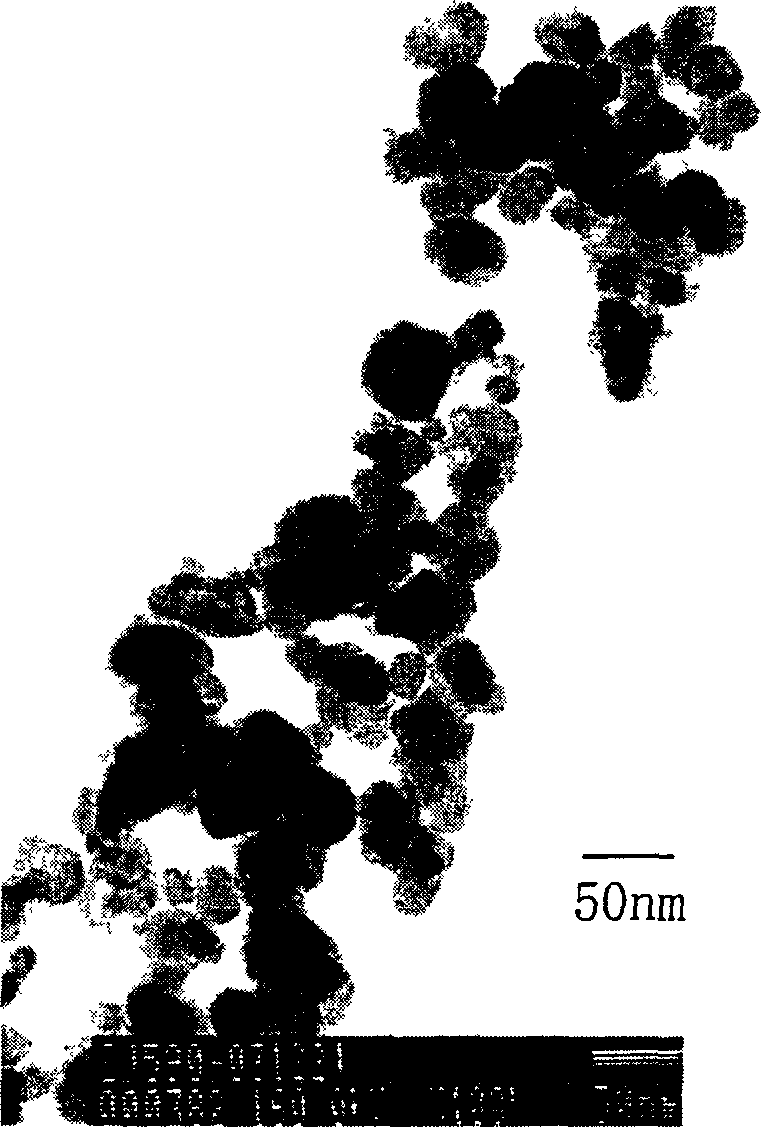

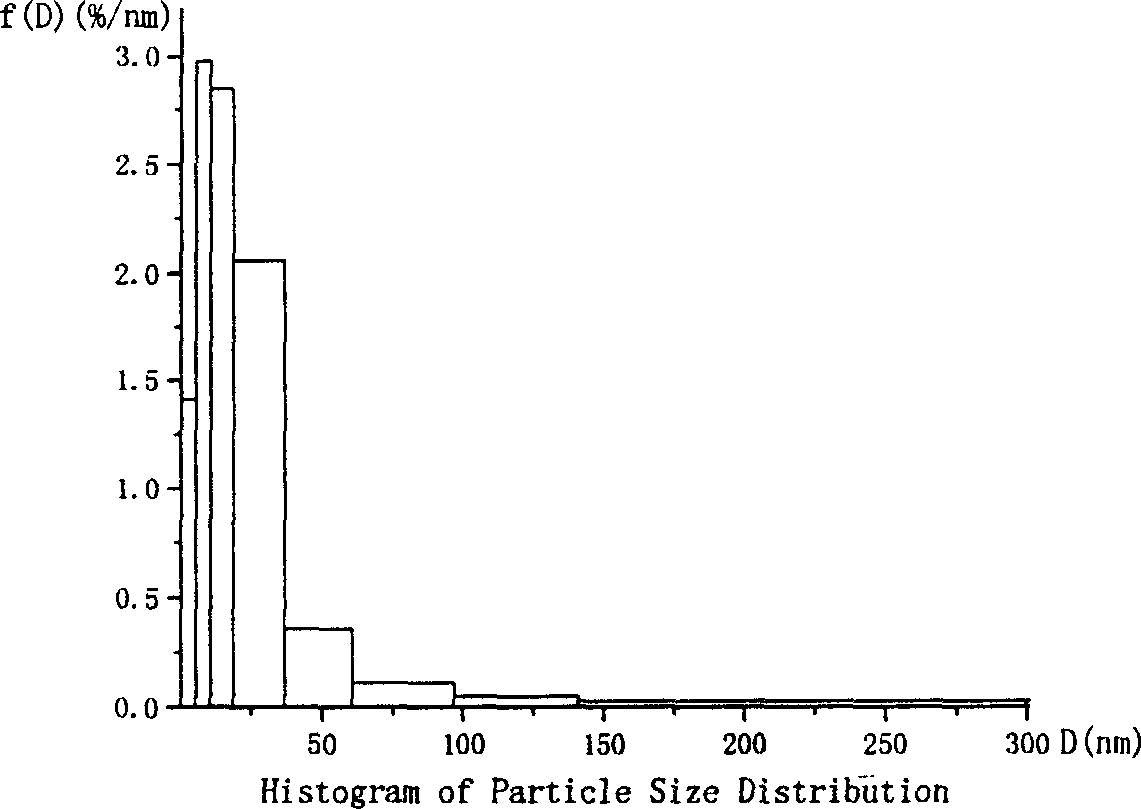

Image

Examples

Embodiment 1

[0039] Raw materials: ammonium tungstate solution (15%), nitric acid, ammonium carbonate ((NH 4 ) 2 CO 3 ), formic acid (HCOOH)

[0040] Measure 100ml of ammonium tungstate solution into a beaker, add 12g of ammonium carbonate and 3g of formic acid, and stir well; heat the solution to 60°C, add 20ml of nitric acid, and form yellow tungstate gel during stirring; take the gel and place it in a dry place for stirring In a container, stir at a temperature of 150°C for 30 to 50 minutes to obtain light yellow nano WO 3 pink.

Embodiment 2

[0042] Raw materials: ammonium tungstate solution (60%), aqua regia (hydrochloric acid: nitric acid = 1:1), ammonium carbonate ((NH 4 ) 2 CO 3 ), industrial acetic acid (HAc)

[0043]Measure 1000ml of ammonium tungstate solution into a beaker, weigh 120g of ammonium carbonate and 200g of acetic acid, and stir evenly; heat the solution to 75°C, add 270ml of aqua regia, and form a yellow tungstic acid gel during the stirring process; take the gel and place it in In a dry mixer, stir at a temperature of 450°C for 60-80 minutes to obtain light yellow powder WO 3 .

Embodiment 3

[0045] Raw materials: ammonium tungstate solution (38.6%), hydrochloric acid, ammonium bicarbonate (NH 4 HCO 3 ), industrial acetic acid (HAc), measure 100ml of ammonium tungstate solution and pour it into a beaker, add 7g of ammonium bicarbonate and 17g of acetic acid, and stir evenly with a glass rod; then heat the solution and keep stirring; when the solution is heated to 70°C, stop Heat, slowly inject 30ml of concentrated hydrochloric acid, stir the solution while adding, the reaction proceeds rapidly; the solution slowly loses fluidity, and finally forms a yellow gel as the temperature decreases; take out the gel and place it in a crucible, and heat it on an electric furnace , and keep the temperature at about 200°C; stir the gel, the water evaporates, and the intermediate product decomposes. After about 40-60 minutes, the final product WO 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com