Quantitatively analyzing method for fluohydric acid in lithium ion battery electrolyte

A lithium-ion battery, quantitative analysis technology, applied in the field of quantitative analysis of hydrofluoric acid in lithium-ion battery electrolyte, to achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

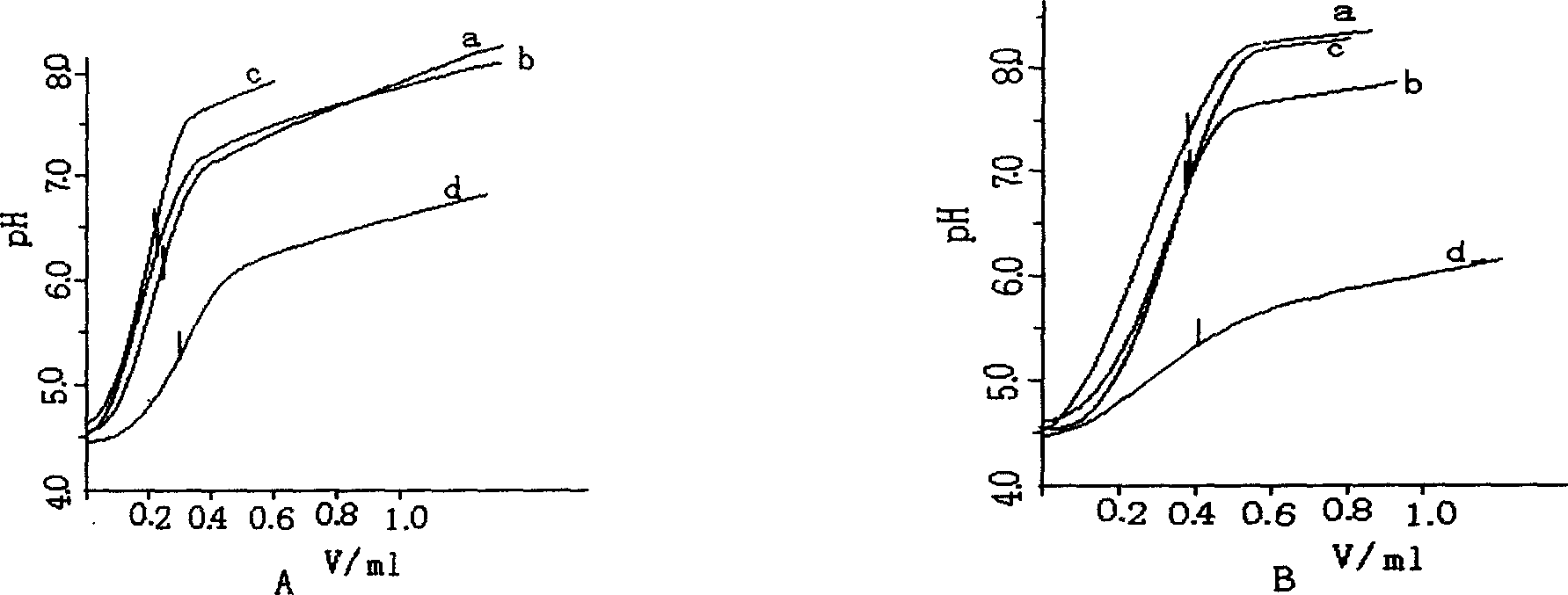

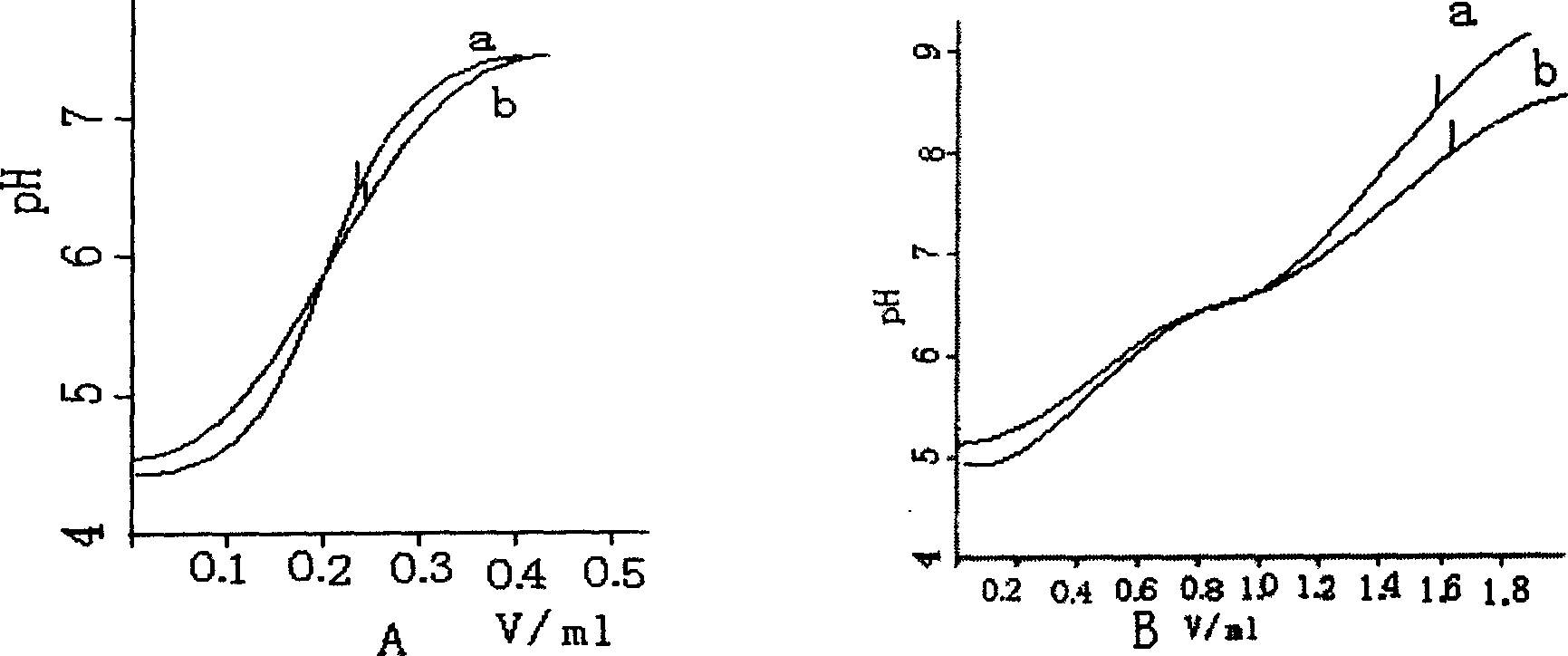

Image

Examples

Embodiment 1

[0017] The first step is to use a dry 10ml PE material syringe to take 8ml of lithium-ion battery electrolyte in the glove box, seal the needle with silica gel, and transfer the syringe to the air; the lithium-ion battery electrolyte is composed of diethyl carbonate (DEC), γ- Butyrolactone (γ-BL) and LiCF 3 SO 3 、LiBF 4 Mixed composition, wherein γ-BL:DEC=1:2(w), the concentration of the two lithium salts is 0.5mol / L;

[0018] In the second step, add 50.0ml of anhydrous methanol (no drying treatment, water content 0.15%) into the titration cup with a pipette, add 2 grams of electrolyte (weigh the amount of electrolyte injected with a balance, accurate to 0.1mg), start stirring;

[0019] The 3rd step selects concentration and is that the potassium hydroxide of 0.0100mol / L is titrant, starts titration, the consumption of electrolytic solution is input in the potentiometric titrator, input second-order derivation program (Switzerland Metrohm company provides) and acidity calcu...

Embodiment 2

[0022] The first step is to use a dry 10ml PE material syringe to take 8ml of lithium-ion battery electrolyte in the glove box, seal the needle with silica gel, and transfer the syringe to the air; the lithium-ion battery electrolyte is composed of propylene carbonate (PC), dimethoxy diethyl ethane (DME) and LiClO 4 , LiAsF 6 Mixed composition, wherein PC:DME=1:2(w), the concentration of the two lithium salts is 0.5mol / L;

[0023] In the second step, add 50.0ml of absolute ethanol with a pipette in the titration cup (no drying treatment, water content 0.2%), add 2.5 grams of electrolyte (weigh the amount of electrolyte injected with a balance, accurate to 0.1mg), start stirring;

[0024] The 3rd step selects the sodium hydroxide that concentration is 0.0500mol / L to be titrant, starts titration, the consumption of electrolytic solution is input in the potentiometric titrator, input second-order derivation program (Switzerland Metrohm company provides) and acidity calculation ...

Embodiment 3

[0027] The first step is to use a dry 10ml PE material syringe to take 8ml of lithium-ion battery electrolyte in the glove box, seal the needle with silica gel, and transfer the syringe to the air; the lithium-ion battery electrolyte is composed of PC, methyl carbonate (DMC), Tetrahydrofuran (THF) and LiN(CF 3 SO 2 ) 2 Mixed composition wherein PC:DMC:THF=2:3:1 (w), the concentration of lithium salt is 1mol / L;

[0028] The second step is to add 50.0ml of absolute ethanol (without drying process, water content 0.2%) into the titration cup with a pipette, and add 3 grams of electrolyte (weigh the amount of injected electrolyte with a balance, accurate to 0.1mg), start stirring;

[0029] The 3rd step selects the lithium hydroxide that concentration is 0.1000mol / L to be titrant, starts titration, the consumption of electrolytic solution is input in the potentiometric titrator, input second-order derivation program (Switzerland Metrohm company provides) and acidity calculation f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com