Super-short pulse laser with Yb dosed optical fiber

A technology of ytterbium-doped fiber and ultra-short pulse, which is applied in the laser field, can solve the problems of reduced stability and reliability of the laser system, loss of mode-locking of the laser, large grating loss, etc., to achieve light weight, avoid spectrum narrowing, and reliability increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

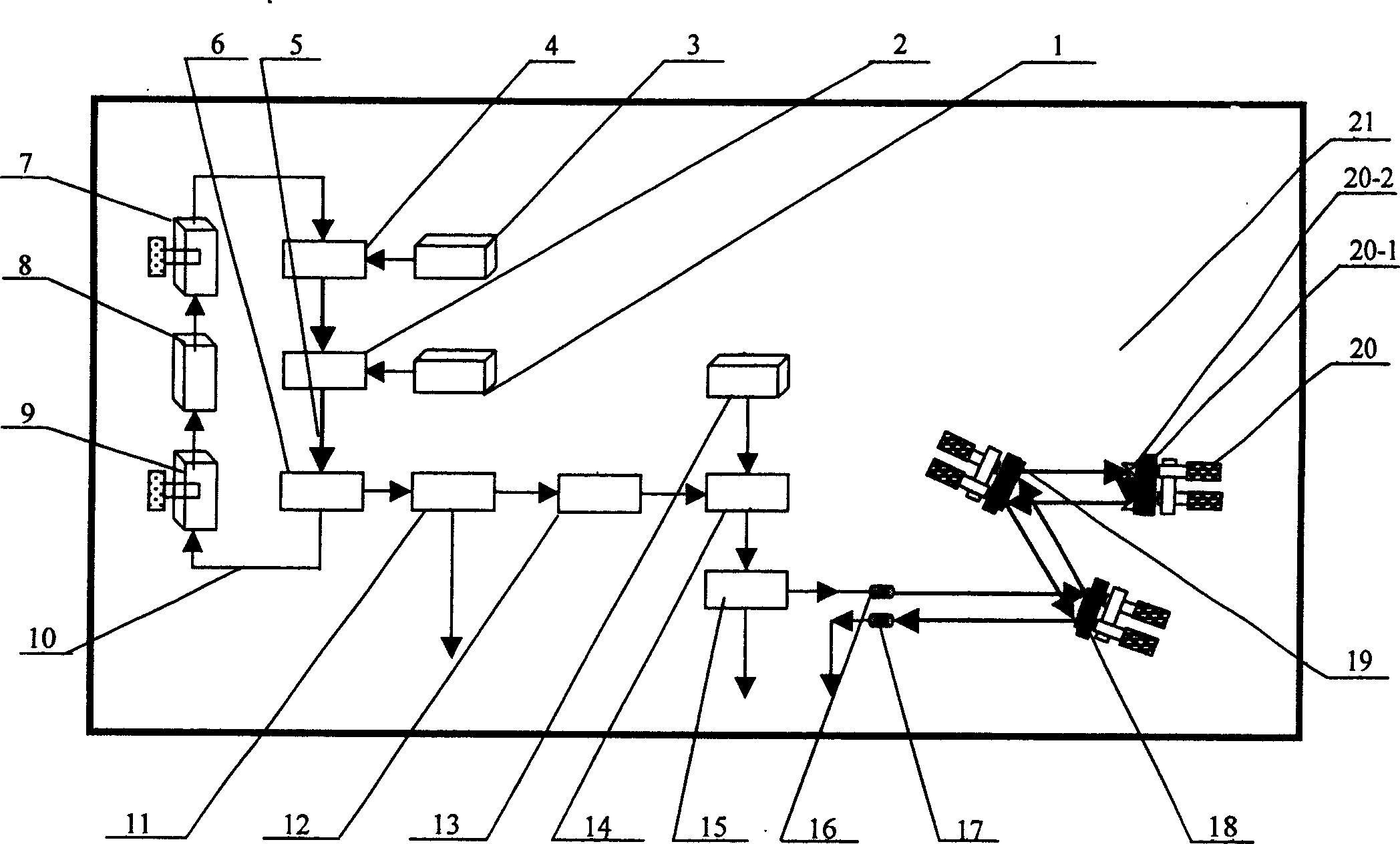

[0017] exist figure 1 Among them, the ytterbium-doped fiber ultrashort pulse laser in this embodiment is composed of an oscillator front-end pump source 1, an oscillator front-end wavelength division multiplexer 2, an oscillator back-end pump source 3, and an oscillator back-end wavelength division multiplexer. 4, ytterbium-doped fiber 5, oscillator output coupler 6, front-end polarization controller 7, polarization-related optical isolator 8, back-end polarization controller 9, ordinary undoped fiber 10, oscillator detection output coupler 11 , polarization-independent optical isolator 12, amplifier pump source 13, amplifier wavelength division multiplexer 14, amplifier detection output coupler 15, collimating coupling lens 16, converging coupling lens 17, diffraction grating 18, collimating grating 19 , a lifting mirror 20, and a mounting plate 21 are connected to form an oscillator, wherein the oscillator front-end pump source 1 to the oscillator detection output coupler 11...

Embodiment 2

[0025] In this embodiment, the total reflection film vacuum-evaporated on the slopes of the two rectangular prisms 20-2 is 3 layers of aluminum oxide coating. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0027] In this embodiment, the total reflection film vacuum-evaporated on the slopes of the two rectangular prisms 20-2 is five layers of aluminum oxide coating. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0028] The working principle of the present invention is as follows:

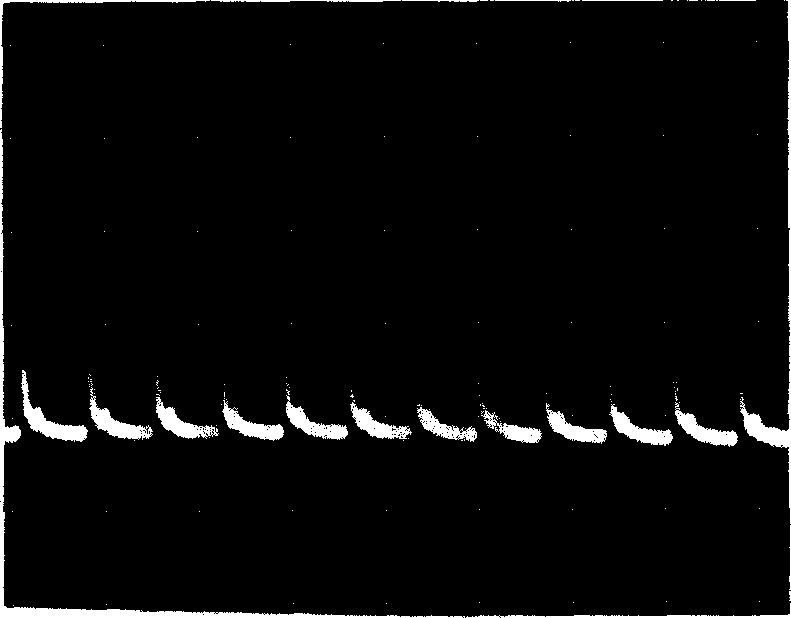

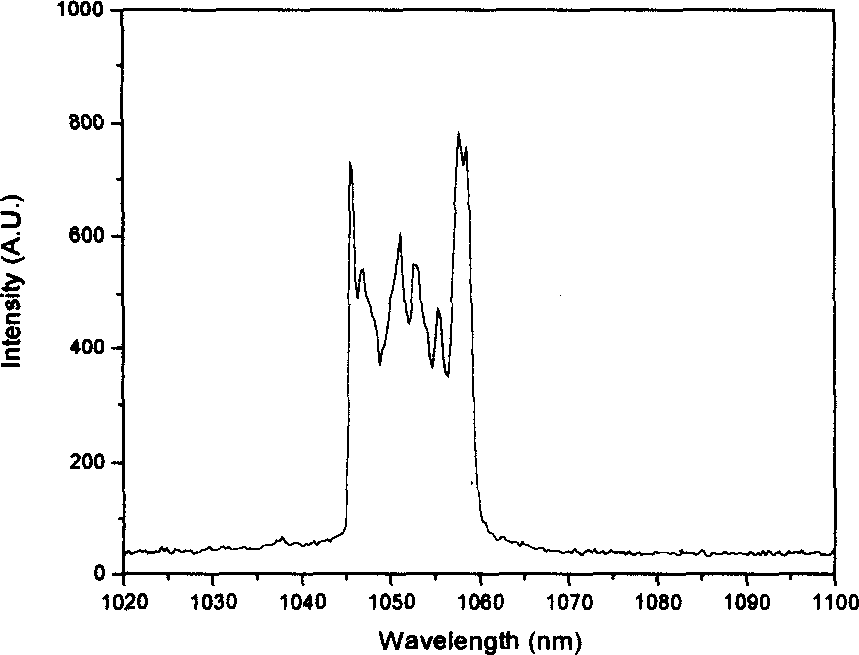

[0029] Add the pump power of the front-end pumping source 1 of the oscillator and the pumping source 3 at the back-end of the oscillator to the maximum value, and the pumping light of the pumping source 1 at the front-end of the oscillator passes through the ordinary undoped optical fiber 10 and passes through the front-end wavelength division of the oscillator. The multiplexer 2 enters the ytterbium-doped fiber 5 to generate continuous laser light, and the pump light of the pump source 3 at the back end of the oscillator passes through the ordinary undoped fiber 10, passes through the wavelength division multiplexer 4 at the back end of the oscillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com