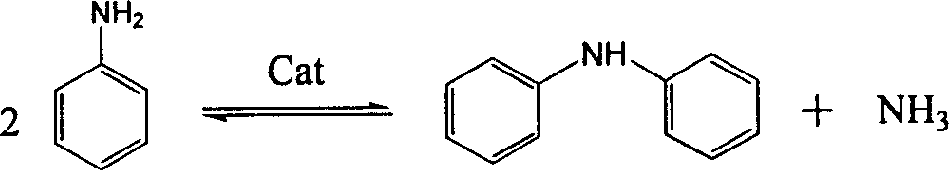

Method for preparing diphenylamine by aniline liquid phase condensation and denitrification coupling

A deamination coupling and aniline liquid technology, which is applied in the direction of condensation/addition reaction to prepare amino compounds, organic chemistry, etc., can solve the problems of affecting the conversion rate of reaction balance, lengthening of residence time, and decrease of selectivity, so as to achieve catalyst utilization and The effect of increased production capacity of the device, convenient operation and control, and reduced energy consumption of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

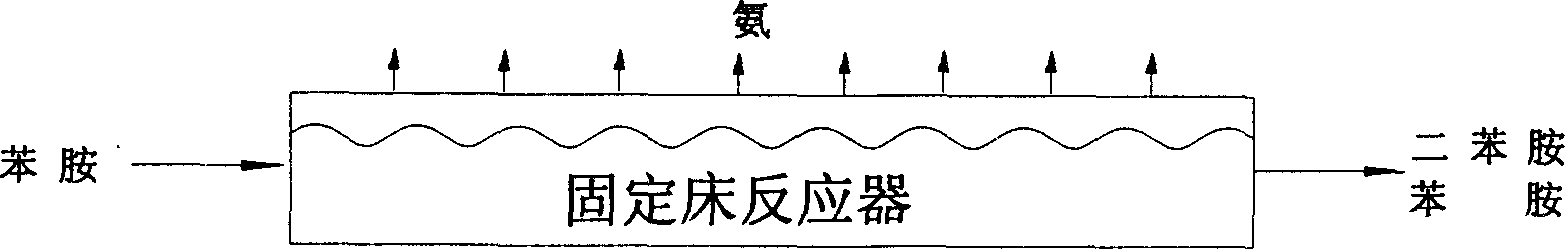

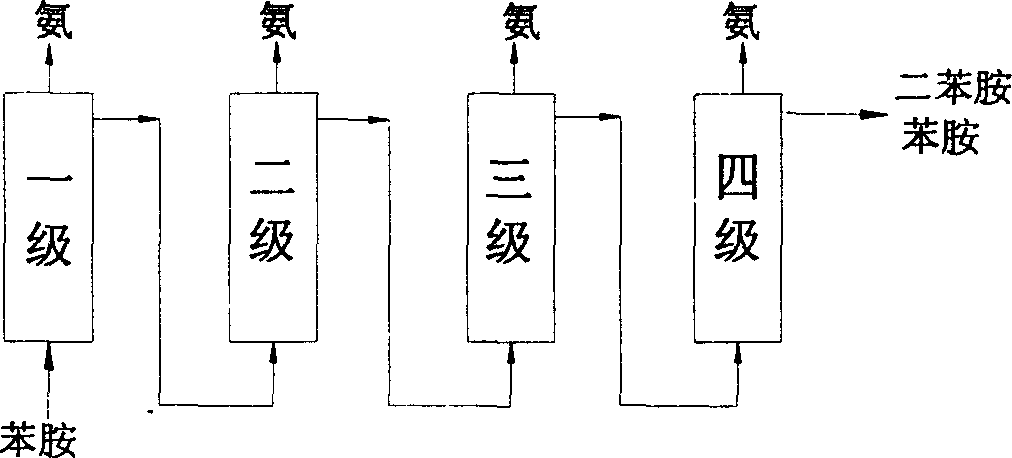

[0021] Four fixed-bed reactors numbered 1, 2, 3, and 4 were connected in series successively, and 6 grams, 12 grams, 24 grams and 48 grams of beta zeolite molecular sieve catalysts were loaded respectively, and the total loading amount of the catalyst was 90 grams. Control the pressure of each reactor to be 2.0MPa and the temperature to be 330°C. After the raw material aniline is pressurized and heated, it is added to the bottom of the first reactor at a speed of 36 g / hour (the space velocity is 0.4 g / g catalyst·hour), followed by Passing through the catalyst beds of the four reactors and exiting from the top of the fourth reactor, samples were taken for analysis of the composition of the reaction mixture. The tops of No. 1, No. 2 and No. 3 reactors are respectively equipped with reflux condensers and valves. When the valves are opened to a certain degree, the deamination can be stabilized while the aniline condensation reaction is carried out. The conversion rates of aniline ...

example 2

[0023] Adopt the same device as example one, catalyst loading, reaction pressure and temperature are also identical with example one. Raw material aniline joins in the reaction system with the speed of 54 grams / hour (space velocity is 0.6 gram / gram catalyst hour), and the aniline conversion obtained under deamination and non-deamination two kinds of operation forms is respectively 18.4% and 23.8%, it can be seen that the conversion rate of aniline has increased by 5.4% because of the coupled deamination and condensation reaction.

[0024] Comparing the results of Example 1 and Example 2, it can be seen that, when the aniline conversion rate is low, deamination is more beneficial to the improvement of the conversion rate.

example 3

[0026] Two fixed-bed reactors filled with 5250 kg of beta zeolite molecular sieve catalysts are connected in series, and the top of each reactor is equipped with a gas-liquid separator, a reflux condenser and a liquid level control system. Control the operating pressure and temperature in the reactor to be 2.0MPa and 320°C respectively. After pressurized and heated, the raw material aniline is added to the first reactor at a rate of 2950 kg / hour (the space velocity is 0.28 g / g catalyst·hour). The bottom, after passing through the catalyst beds of the two reactors, leaves the reaction system from the top of the second reactor. According to the analysis and measurement, the aniline conversion rates under deamination and non-deamination operation conditions are 26.6% and 24.5% respectively, and the coupling of deamination and condensation makes the aniline conversion rate increase by 2.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com