City internal river watercourse desilting construction process

A construction technology and river channel technology, applied in the direction of earth mover/excavator, construction, etc., can solve the secondary pollution of the backwater of the mud discharge field, the inability to desilt in place at the bank slope tooth foot and the operation under the bridge at one time, and the cost advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail by taking the dredging construction of an inland river in a large city with a population of about 8 million as an example.

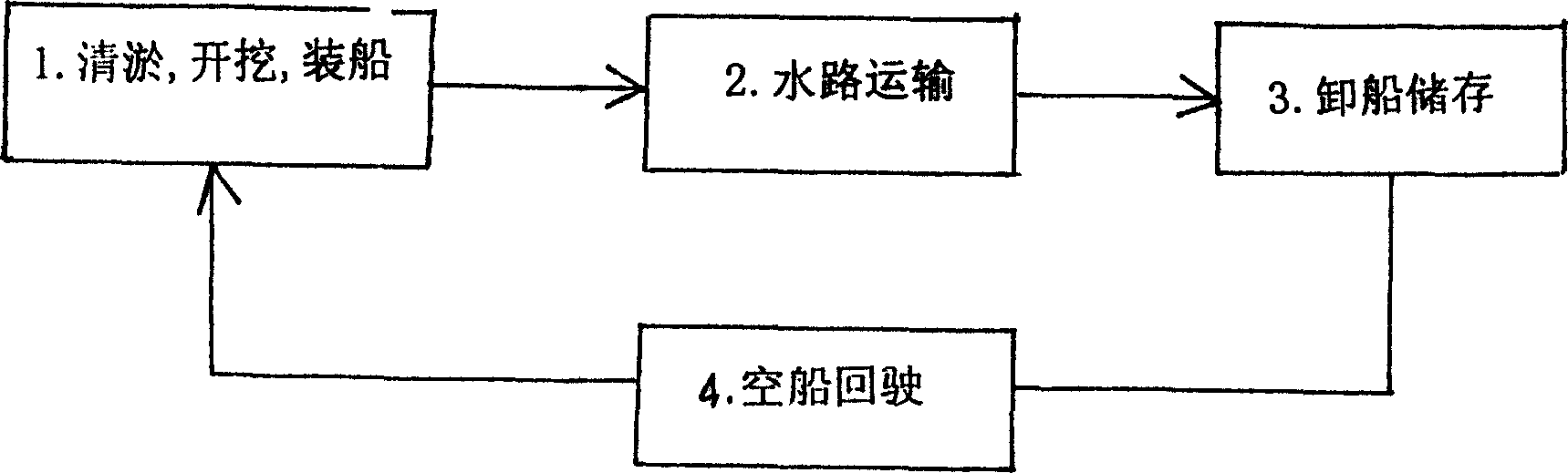

[0031] According to the city's characteristics as a metropolis, a large population, and rivers passing through the city. Developed a detailed construction process: see the process flow chart figure 1 .

[0032] (1) Underwater dredging, excavation and loading:

[0033] Equipment: pontoon type pontoon, hydraulic grab, excavator.

[0034] Process: The three sets of equipment of pontoon type pontoon, hydraulic grab, and excavator are assembled into a pontoon type hydraulic grab machine at the dredging river site; the machine has two-way adjustable positioning piles and a self-adjusting positioning system. Excavation and dredging on the river course; the silt is loaded into the semi-bunk mud barge by hydraulic grab machine.

[0035] Detailed description: The pontoon type hydraulic grab machine is a pontoon with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com